Automobile body front longitudinal beam structure and automoible

A technology of automobile body and front longitudinal beam, which is applied in the substructure, vehicle parts, transportation and packaging, etc. It can solve the problems of low energy absorption efficiency of beam structure, endangering the life safety of passengers, and large intrusion of passenger compartment, etc., and achieves the goal of unit energy High absorption efficiency, reduced occupant damage, and expanded design space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the front longitudinal beam structure of the automobile body involved in the present invention will be further described in detail in conjunction with the accompanying drawings and embodiments.

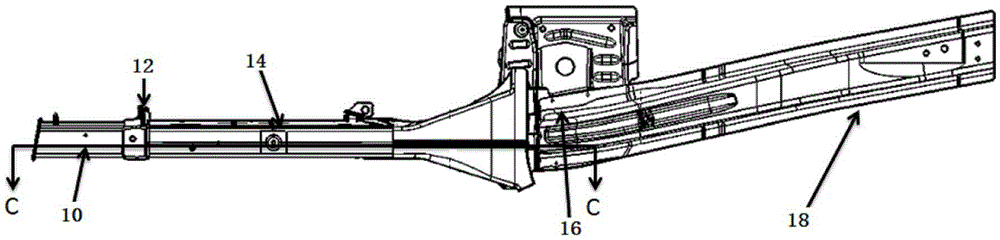

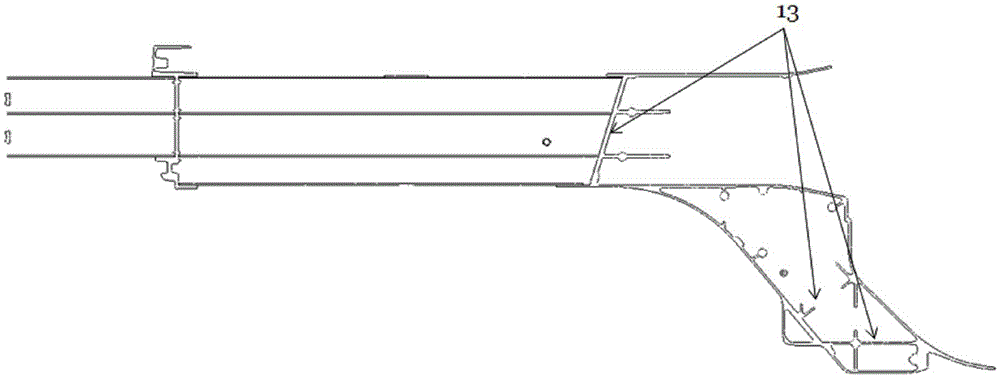

[0040] see figure 1 , figure 2 , image 3 and Figure 4 As shown, one embodiment of the present invention provides a front side beam structure of an automobile body, which includes a front side beam main body, and the front side beam main body includes a front section made of aluminum and a rear section made of steel. Wherein, the front section includes a crash box section 10 , a connector section 12 , a straight beam section 14 and a bent section 16 which are sequentially connected from front to back. The rear section includes a rear beam section 18 .

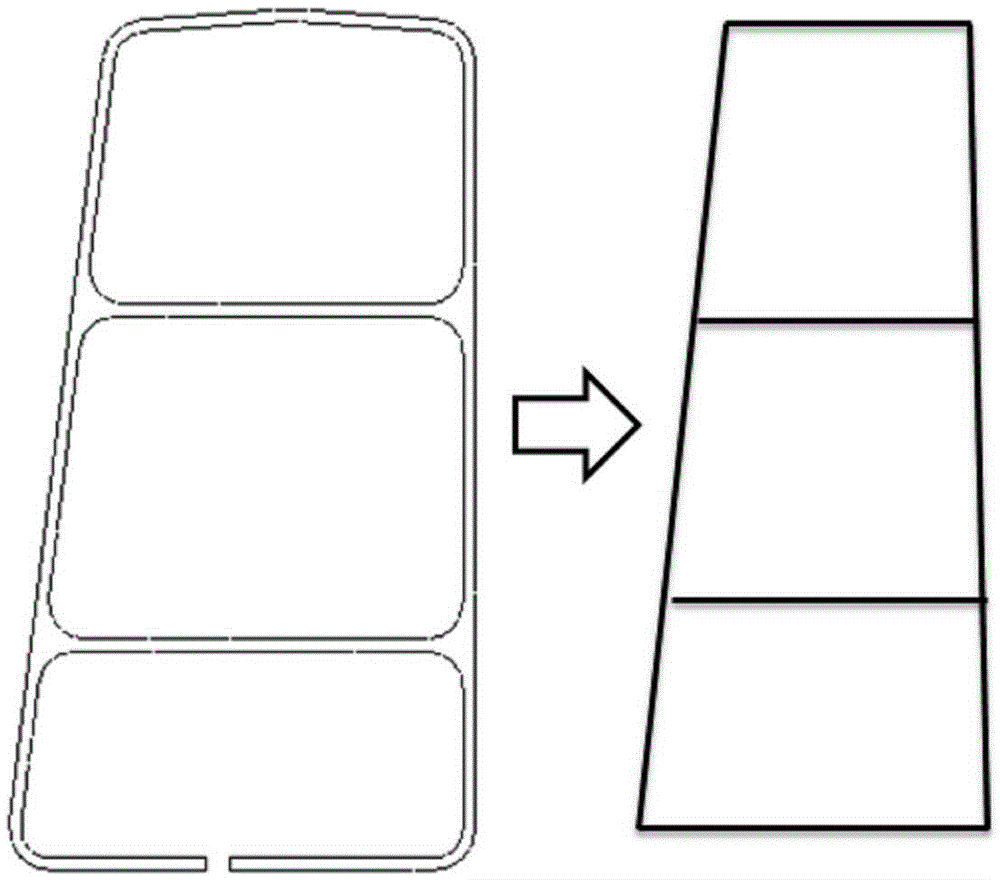

[0041] see Figure 5 and Figure 6 As shown, the cross sections of the energy-absorbing box section 10 and the straight beam section 14 of the front section respectively adopt the configuration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com