A production line of oral film coating machine

A film coating machine and production line technology, which is applied in the direction of transportation packaging, packaging, transportation and packaging, etc., can solve the problems of complex manual coating, high labor cost, poor efficiency, etc., and achieve the effect of solving manual processing and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly and completely described below.

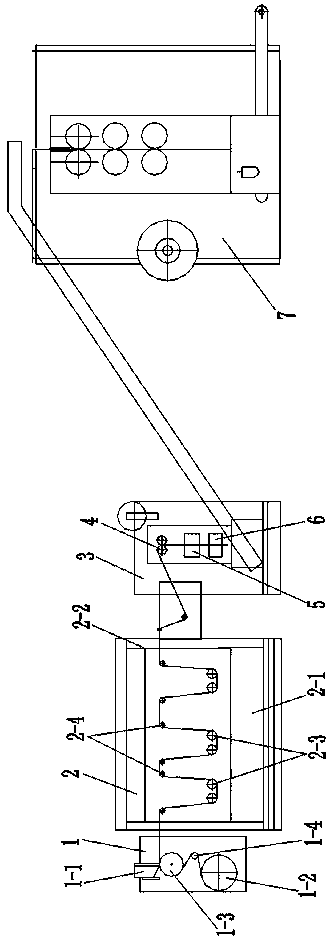

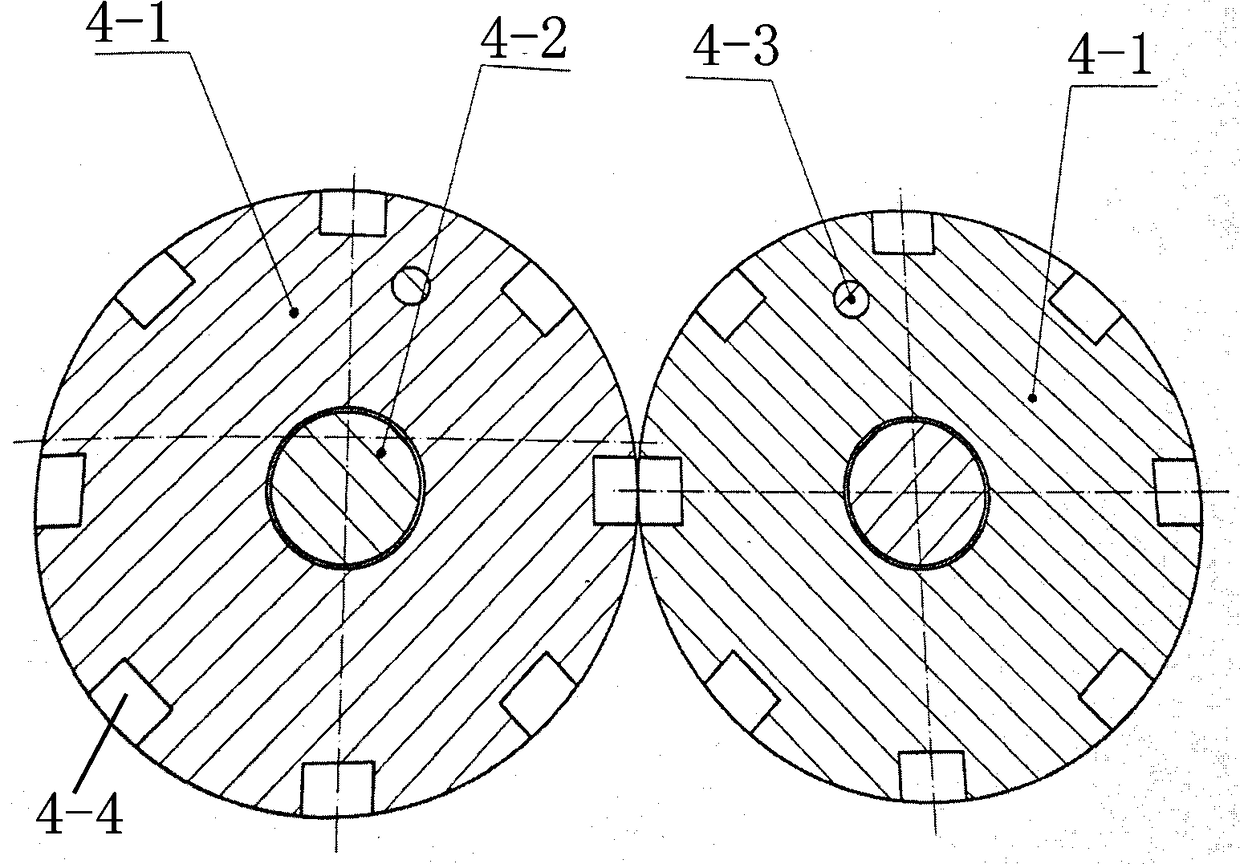

[0017] Such as figure 1 Shown, the production line of oral film coating machine of the present invention, it comprises film coating mechanism 1, the coating film preheating shaping machine 2 that is communicated with the film outlet of coating film mechanism, communicates with the film outlet of coating film preheating shaping machine Sealing film cutting bag mechanism 3, and the bag making machine packaging machine 7 (prior art) that is connected with sealing film cutting bag mechanism by conveyer belt, the oral cavity film raw material on the film coating mechanism is passed through the motor and the gear mechanism on the preheating setting machine. The driven upper and lower tension rollers provide power for film release.

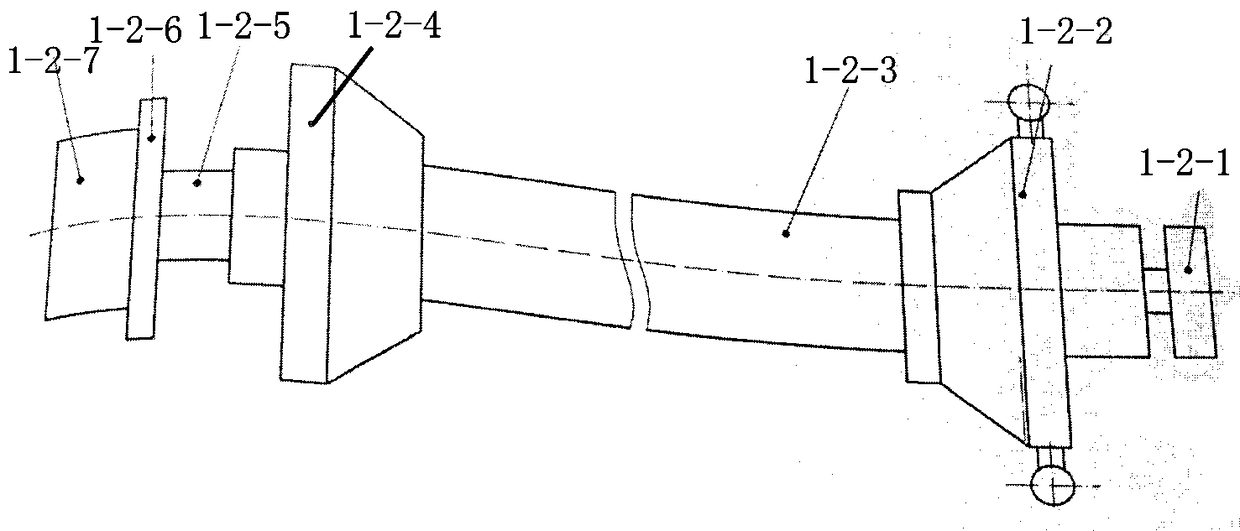

[0018] The film coating mechanism 1 includes a dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com