Fine wire guiding device

A guiding device and thin wire technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of wire resistance influence, large conveying resistance, and influence on wire conveying process, etc. Effect of large wire conveying force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

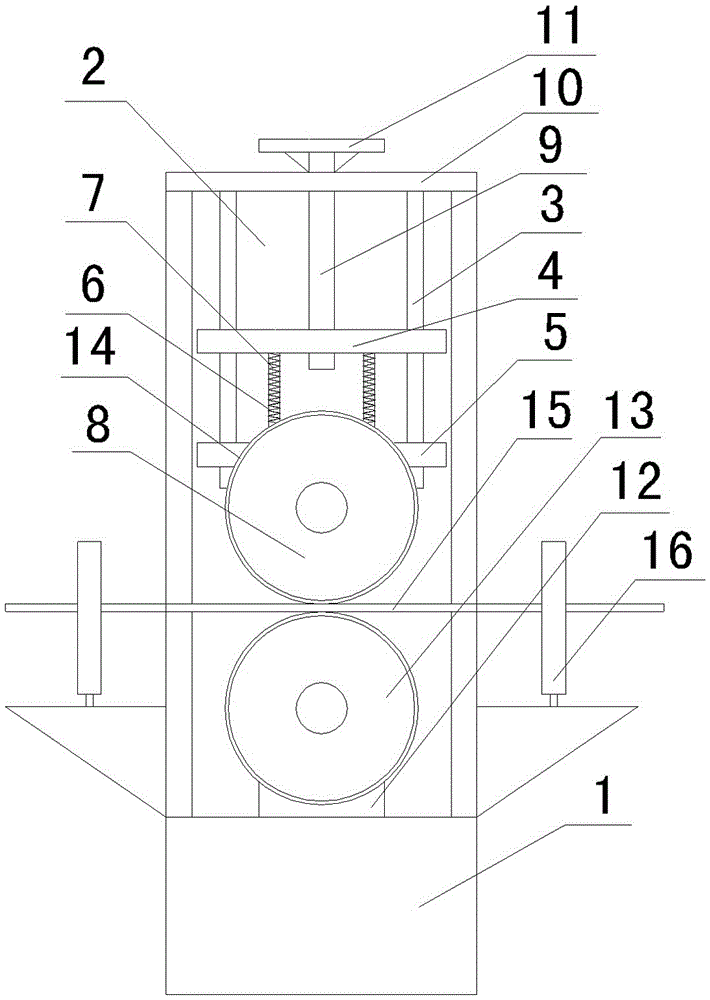

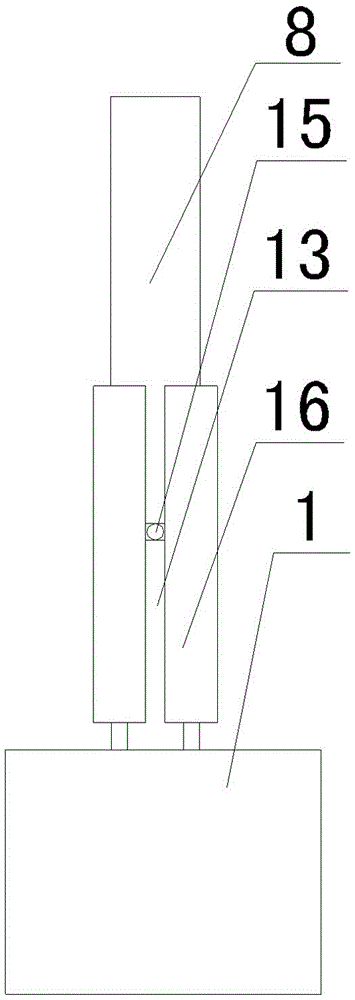

[0009] See figure 1 , figure 2 As shown, a thin wire guiding device includes a base 1, a groove space 2 is opened on the base 1, vertical guide rods 3 are installed on both sides of the upper end of the groove space 2, and a mobile seat is set on the vertical guide rod 3. The moving seat includes an upper plate 4 and a lower plate 5 with guide holes matched with the vertical guide rod 3 and an intermediate link 6 connecting the upper plate 4 and the lower plate 5. The intermediate link 6 is covered with a spring 7, and the effect of the spring is It can make the upper plate 4 and the lower plate 5 be supported by a certain elasticity, which can offset some shaking caused by the rotation of the upper guide wheel 8 on the lower plate 5. There is a threaded hole in the middle of the upper plate 4, and a screw rod is installed in the threaded hole. 9. The upper end of the screw 9 is a polished rod and runs through the top plate 10 of the base 1. A rotating handle 11 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com