Railway track rust removal vehicle

A railway track and main body technology, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of complex structure of grinding car, high operation difficulty, poor cleaning effect, etc., and achieves the advantages of manual handling and use, the same smoothness, and mobile convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

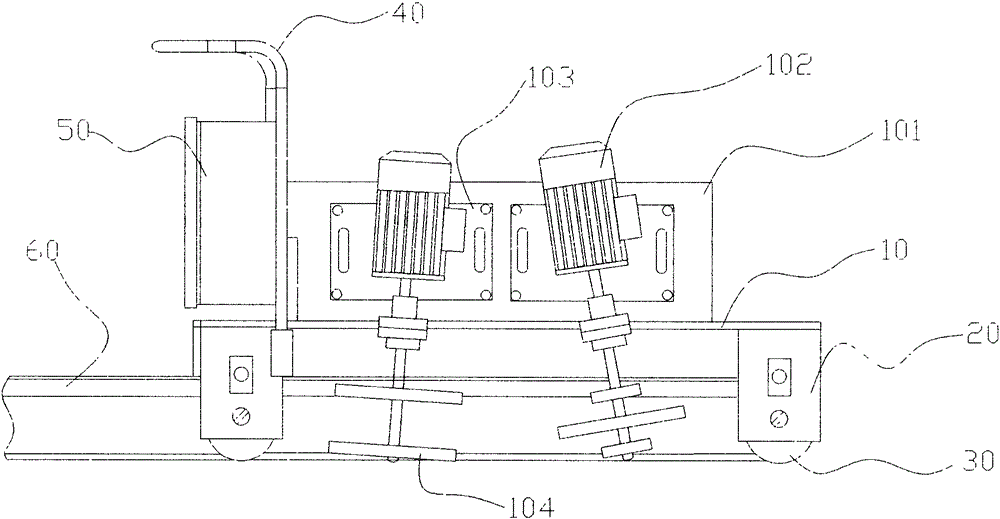

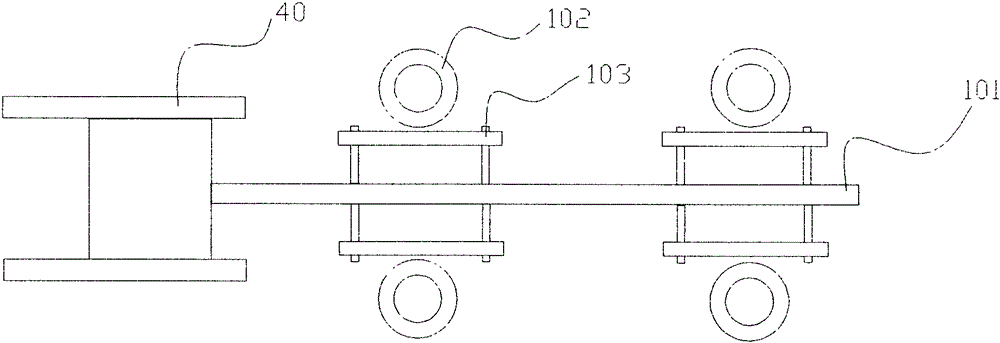

[0021] Such as figure 1 , figure 2 Shown, a kind of derusting vehicle for railway tracks comprises a derusting vehicle main body 10 sliding along railway tracks 60 and parallel wire wheels 104 that are arranged on both sides of the derusting vehicle main body 10 and rub against railway tracks 60. The car main body 10 is provided with a motor 102 and a motor plate 101, and a plurality of motor seat plates 103 are respectively arranged on both sides of the motor plate 101. The motor seat plate 103 is provided with an arc-shaped displacement hole, and the motor 102 is passed through by a fixing bolt. It is fixed on the motor seat plate 103 through the displacement hole, and the inclination angle of the motor 102 can be changed by changing the position of the fixing bolt in the displacement hole. The rotating shaft of the motor 102 is provided with multiple parallel wire wheels with different radii 104.

[0022] Specifically, the parallel wire wheels 104 on the motor 102 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com