Installation process for back well drilling type platform sleeving-free wellhead

An installation process and drilling technology, which is applied in the field of offshore petroleum engineering to achieve the effect of saving workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

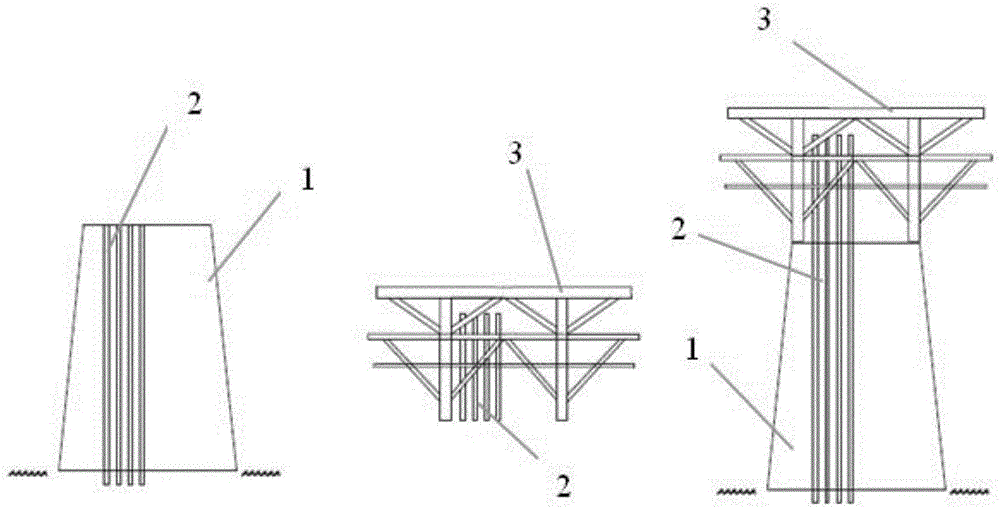

[0020] Such as figure 1 As shown, the present invention adopts the following installation steps:

[0021] Step 1: Optimize the 2 sections of the riser sleeve, divide the riser 2 into three or four sections, and make the first two or three (depending on the specific design requirements) penetrate the seabed to reach the design entry Mud depth, and reserve the end section of the riser 2;

[0022] Step 2: Install jacket 1 at sea;

[0023] Step 3: Install the first two sections or the first three sections (depending on the specific design requirements) of the water riser 2 at sea to reach the design depth of mud penetration and meet the design standards after penetrating into the seabed;

[0024] The fourth step: construct the upper module 3 on land, and install and fix the last section of the riser 2 in the wellhead area of the upper module 3;

[0025] The fifth step: marine transportation of the upper module 3 and the terminal water-proof casing 2 fixed on the upper module 3;

[0026] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com