Post-construction method of reinforced-concrete-poured interior wall

A technology for pouring concrete interior walls and post-construction, which is applied in the treatment of walls and building materials, construction, etc., can solve problems such as difficulty in pouring and construction of interior walls of vaults, and achieve the effect of saving construction period, meeting waterproof needs, and saving project cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

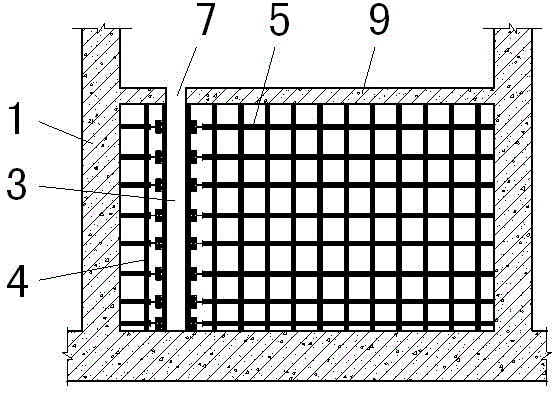

[0018] Such as figure 1 As shown, some post-pouring holes 7 are reserved when pouring the roof 9, and when the interior wall 3 is being constructed, the concrete delivery pipe is inserted between the templates on both sides of the interior wall through the post-pouring holes 7 to complete the pouring of the interior wall 3.

Embodiment 2

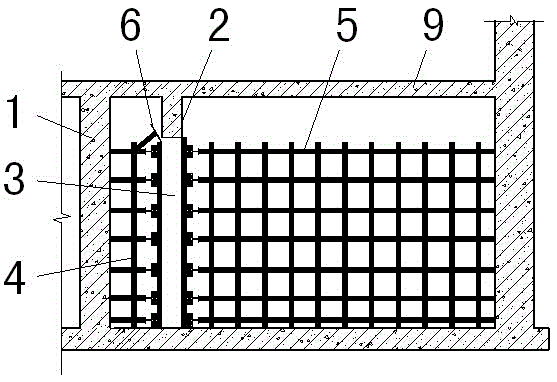

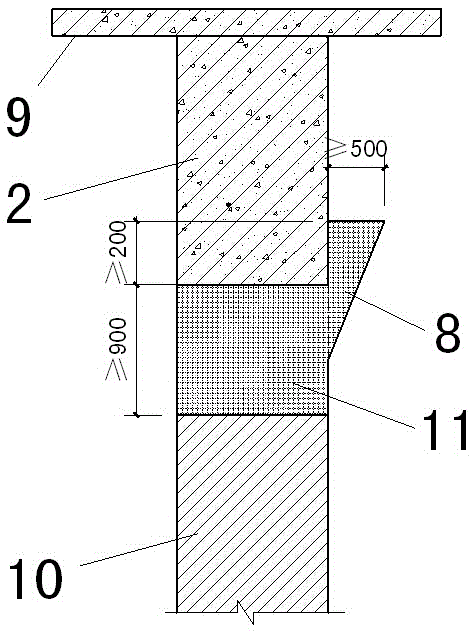

[0020] Such as figure 2 As shown, when pouring the structural beam 2 and the roof 9, the post-pouring hole 7 is not reserved. When the interior wall 3 is constructed, the segmented pouring method is adopted. For the pouring of the wall 11, a corbel-like inclined plate 6 is made on the formwork of the upper inner wall, and the pouring of the upper inner wall 11 is completed from the side of the inner wall through the inclined plate 6 similar to the corbel. 8. Remove the corbel-like concrete mix 8.

[0021] Concrete implementation steps of the present invention:

[0022] 1 1. Plate-tied steel bars: the 3 vertical steel bars on the inner wall are bound, the upper and lower section steel bars are staggered and overlapped by 50%, and the length of the steel bars in the wall extending into the upper structural beams is in accordance with the design drawings and 11G101-1 atlas. The junction of the inner wall 3 and the structural beam 2 must first be stretched and planted wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com