Omni-directional prestress antifatigue combined steel structure wind tower and construction method thereof

A steel structure and prestressing technology, applied in wind power generation, installation/support of wind turbine configuration, etc., can solve the problems of increased consumption of structural materials and low allowable stress amplitude of fatigue, so as to eliminate fatigue problems, facilitate construction and save money material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

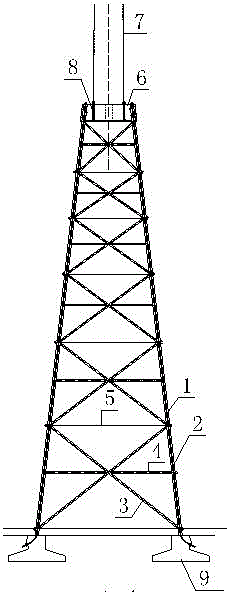

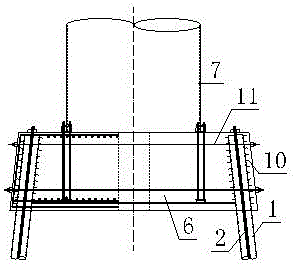

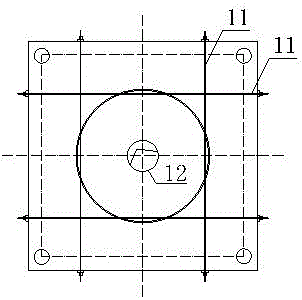

[0023] Such as Figure 1-Figure 3 As shown, an omnidirectional prestressed anti-fatigue composite steel structure wind tower is composed of a lattice tower, a concrete transition section 6 and a steel structure tower tube 7 .

[0024] In this embodiment, the lattice tower includes a foundation 9, a tower column 1, a stud 10, a steel strand 2, a diagonal bar 3, a cross bar 4 and a diaphragm 5, and the steel strand 2 is connected from the The inner bottom of the tower column 1 penetrates to the inner top of the tower column 1, and the stud 10 is welded at the end of the tower column 1, and the stud 10 is used to strengthen the transition section between the tower column 1 and the concrete 6, the bottom of the tower column 1 is also provided with a cable, and the bottom of the tower column 1 is jointly anchored to the bottom of the tower column 1 with the lower end of the cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com