Self-adaption automatic-adjusted friction wheel installation driving device

A technology of automatic adjustment and drive device, applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc., can solve the problems of complex design, poor transmission performance, large space occupation, etc., to reduce the volume and facilitate installation and disassembly. , The effect of simplifying the transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

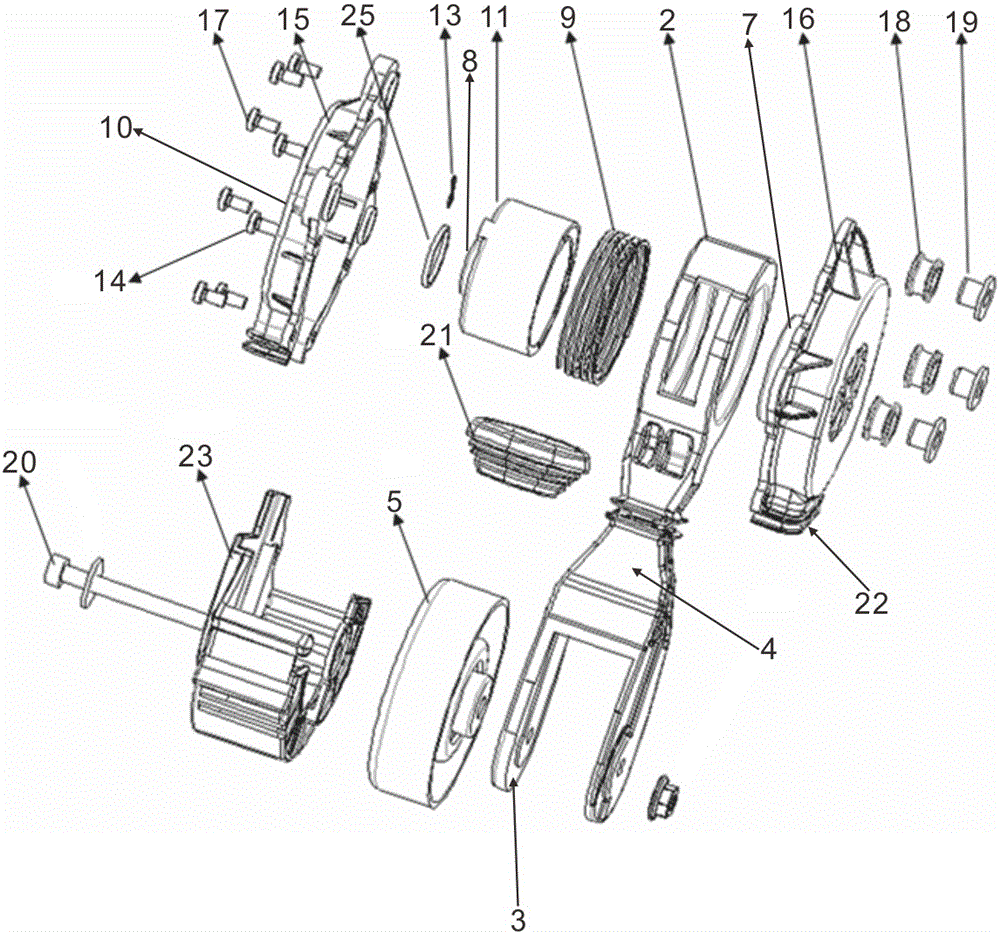

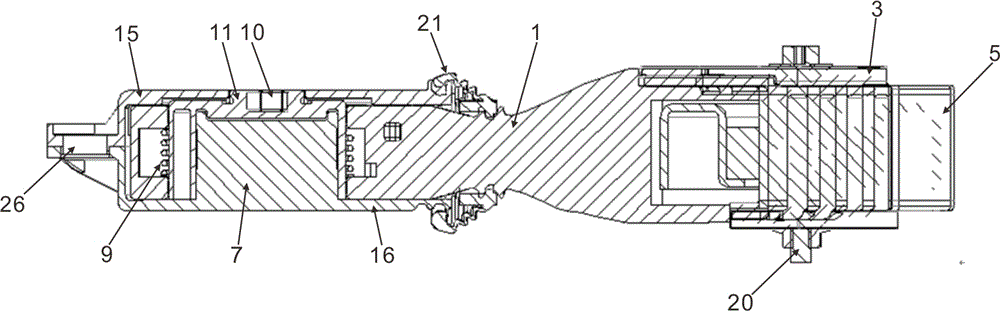

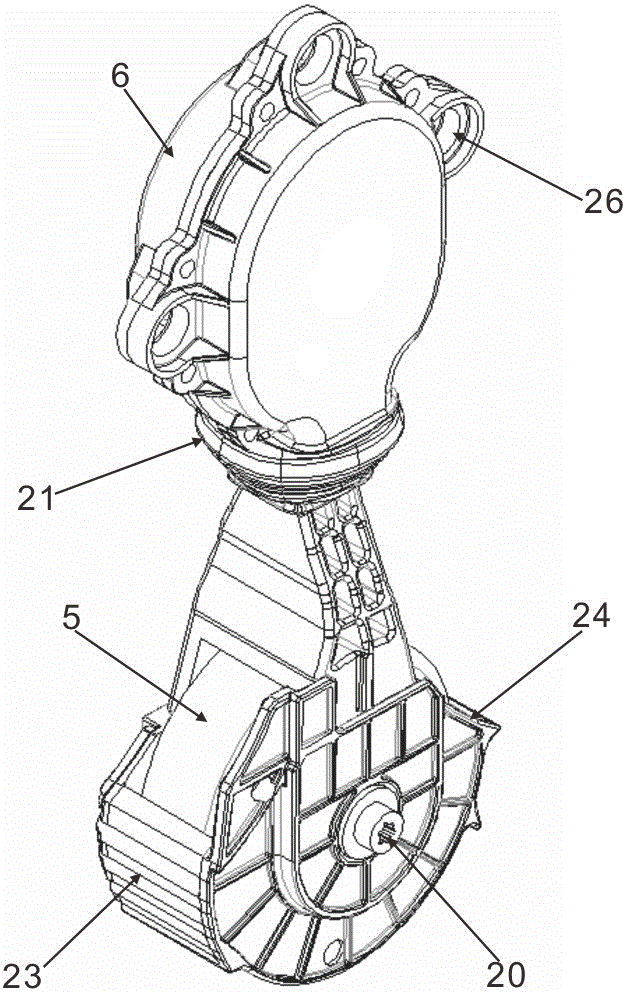

[0030] The present invention provides a self-adaptive and self-adjusting friction wheel mounting drive device, which includes a rocker arm 1 , an outer shell 6 , an eccentric drive wheel 11 , a torsion spring 9 , a limit mechanism and a friction wheel 5 .

[0031] The rocker arm 1 is one of the installation and driving bodies of the friction wheel. The rocker arm 1 includes an eccentric end 2, a U-shaped installation end 3 and a connecting arm 4 connecting the eccentric end and the installation end. The eccentric end 2 has a cavity for accommodating the eccentric drive wheel , The friction wheel 5 is installed in the U-shaped mounting end. Driven by the eccentric drive wheel 11 , the eccentric end 2 can rotate eccentrically within a certain range, so that the front and rear positions of the mounting end 3 change accordingly within a certain range.

[0032] The friction wheel 5 can rotate in the installation end 3, and the specific installation method can preferably be provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com