LED street lamp capable of achieving high solar energy utilization ratio

A technology of LED street light and utilization rate, applied in the direction of energy-saving lighting, circuit layout, components of lighting devices, etc., can solve the problems of low utilization rate of solar energy conversion, single fixing method of solar LED street light, complicated structure, etc., to improve conversion and utilization. efficiency, improved convenience, and the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

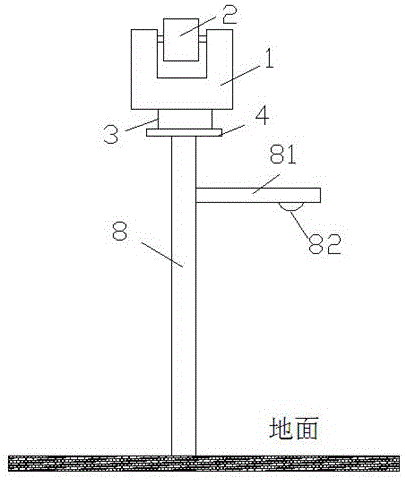

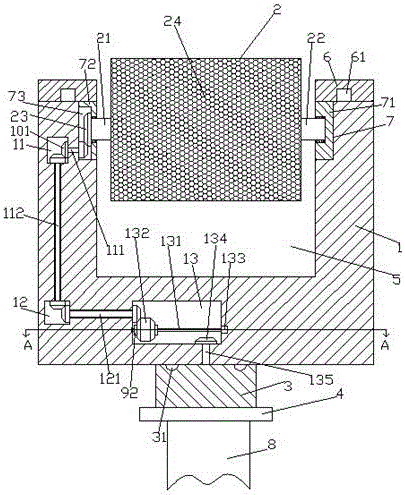

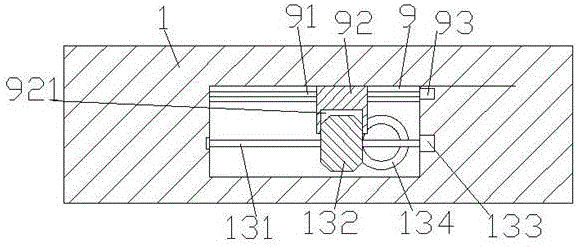

[0021] Such as Figure 1-Figure 5 As shown, an LED street lamp with high solar energy utilization rate of the present invention includes an assembly frame 1 with an assembly groove 5 on the inner top and an assembly seat 3 that is rotationally connected to the bottom of the assembly frame 1. The assembly groove 5 An assembly board 2 is provided inside, and a solar photovoltaic panel 24 is provided on the front end of the assembly board 2, and a first steering shaft 21 and a second steering shaft 22 are respectively provided on the left and right sides of the assembly board 2, and the first steering shaft 21 A first sliding block 72 is connected to the tail end of the left side by rotation and fitting, and a slot 73 is arranged in the first sliding block 72, and a first sliding block fixedly connected with the first steering shaft 21 is arranged in the slot 73 . Three gears 23, the tail end on the right side of the second steering shaft 22 is rotatably connected with a second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com