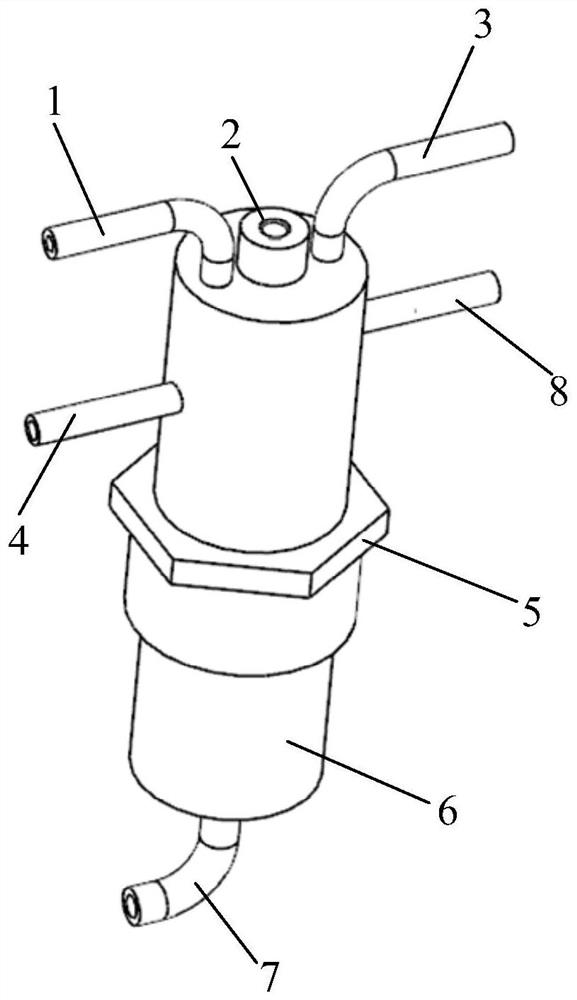

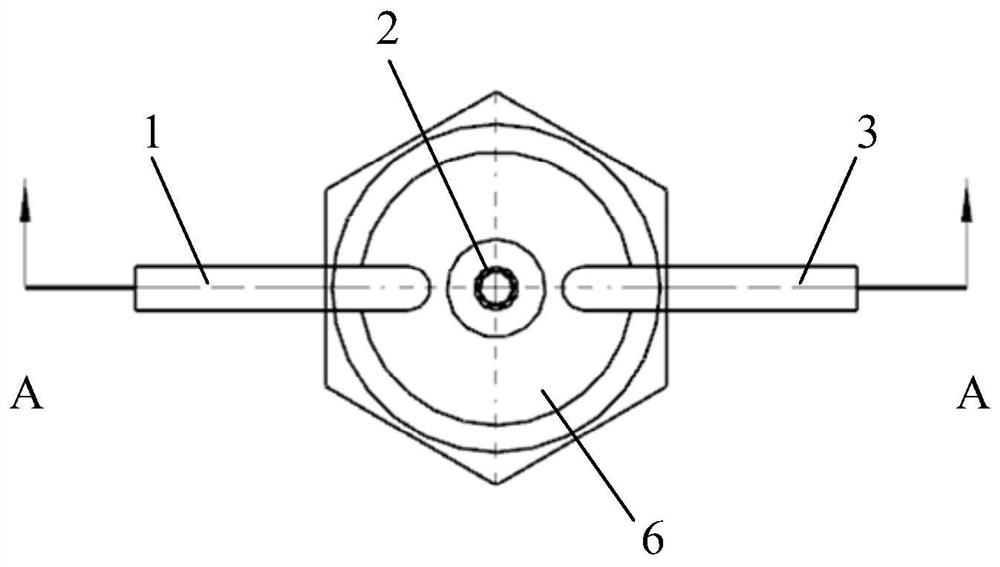

A pressure sensor cooling device suitable for high temperature environment testing

A technology of pressure sensor and cooling device, applied in the direction of measuring device, measuring fluid pressure, instrument, etc., to achieve the effect of improving thermal adaptability, realizing total pressure or static pressure measurement, and facilitating real-time working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

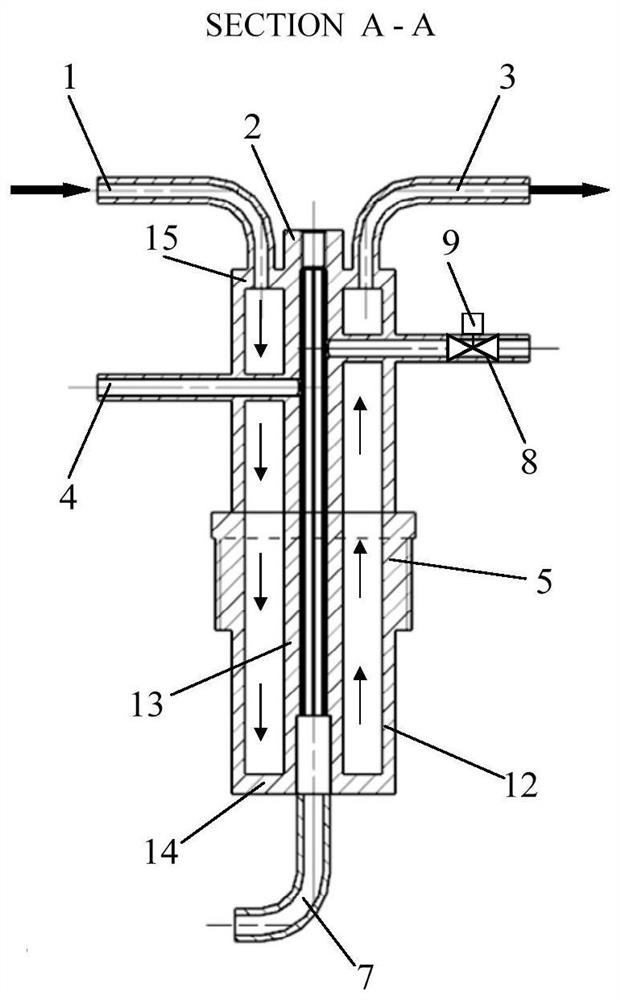

[0034] In this embodiment, the cooling heat exchange structure 6 is 80 mm long, the outer wall 12 of the cooling cavity and the inner wall 13 of the cooling cavity are arranged coaxially, the outer diameter of the outer wall 12 of the cooling cavity is 25 mm, the inner diameter is 21 mm, the wall thickness is 2 mm, and the outer diameter of the inner wall 13 of the cooling cavity is 9 mm. The inner diameter is 5mm and the wall thickness is 2mm. The inner surface of the cooling chamber inner wall 13 from the cooling chamber bottom plate 14 is designed with a M6×0.5 standard internal thread with a length of 15mm. The cooling chamber bottom plate 14 and the cooling chamber cover plate 15 have a wall thickness of 2mm; The plate 10 is 70mm long and 2mm thick, and is connected to the outer wall 12 of the cooling cavity and the inner wall 13 of the cooling cavity, and divides the annular space formed between the outer wall 12 of the cooling cavity and the inner wall 13 of the cooling c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com