Serial sealed combustor device and testing method of relationship of explosive combustion speed, and pressure and temperature

A burning rate and burner technology, which is applied in the field of explosive performance testing, can solve the problems of narrow application range, difficult realization, and difficult control, and achieve the effects of high burning rate, good data stability, and small device volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

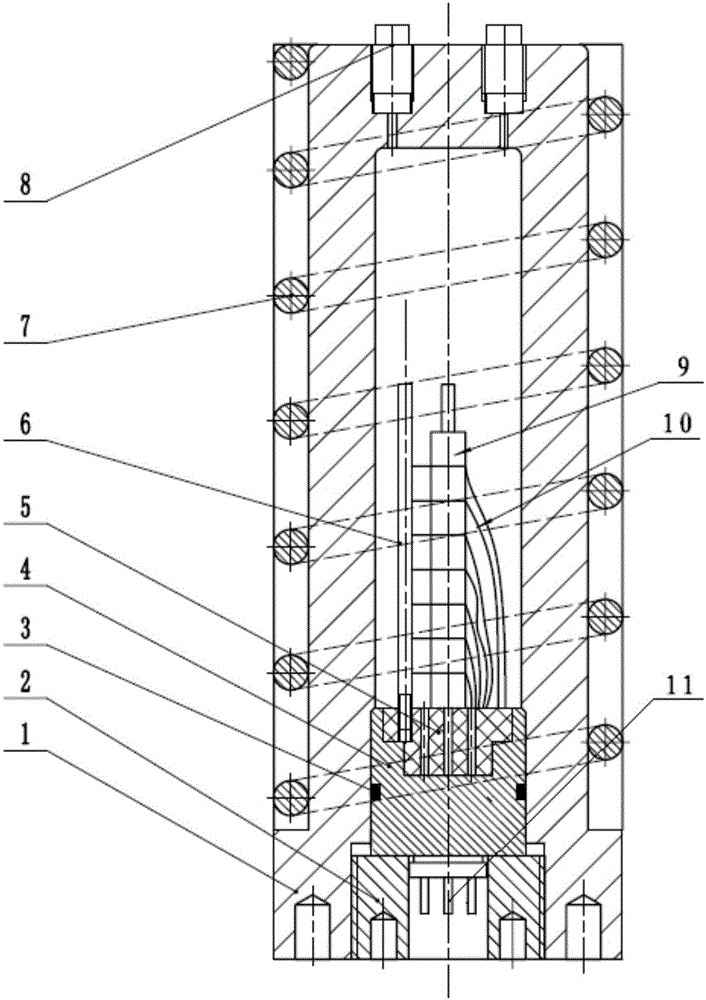

[0030] A tandem airtight burner device, which is composed of a cylinder body 1, a sealing member and a heater 7; the upper end of the cylinder body is sealed, and a pressure sensor 8 is provided through the upper end wall of the cylinder body; the lower end of the cylinder body Opening, a seal is installed at the opening of the lower end, the seal is composed of a fixed ring 4 and an insulating plug 5, the fixed ring is provided with a slot that can fix the insulating plug, and the insulating plug is fixedly installed on the fixed ring In the card slot of the fixed ring, there is also a ring of O-ring 3 around the fixed ring; a terminal 11 is installed under the fixed ring, and a guide hole is opened on the insulating plug, and the guide hole is matched with the terminal setting; and the terminal is radially fixed by the fixing ring, and axially fixed by setting the compression nut 2 at the lower end of the terminal; the heater is uniformly arranged outside the cylinder wall. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com