Energy-saving rotating-speed measuring device of ship main engine

A technology for ship main engine and speed measurement, which is applied in measuring devices, linear/angular velocity measurement, speed/acceleration/impact measurement, etc., can solve problems such as low accuracy, poor real-time performance, and unfavorable speed adjustment of ship main engine, and achieve energy saving The management of consumption reduction and the effect of energy saving and consumption reduction management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

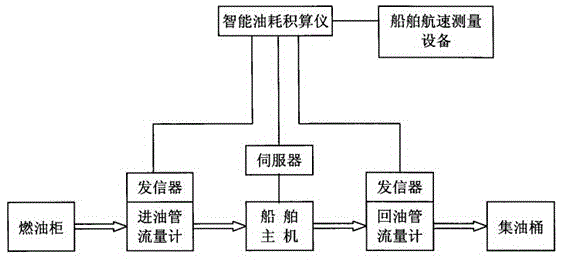

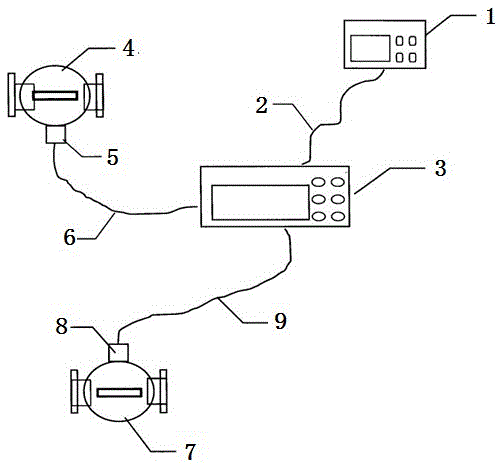

[0013] like figure 1 As shown, the present invention discloses an energy-saving rotational speed measuring device for a main engine of a ship, which includes a speed measurement device, a fuel consumption measurement device connected to the main engine of the ship for calculating fuel consumption, and a device for electrically connecting the fuel consumption measurement device and the speed measurement device. Fuel consumption calculator for calculating unit distance fuel consumption. The speed measuring device is a speed log or a GPS terminal. The fuel consumption measuring device includes an oil inlet pipe flowmeter and an oil return pipe flowmeter, and the oil inlet pipe flowmeter and the oil return pipe flowmeter are respectively connected to the oil inlet and the oil outlet of the main engine of the ship. A signal sender is also arranged on the flow meter to be electrically connected with the intelligent fuel consumption calculator. A server is connected between the shi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com