Display screen for supporting full screen optical fingerprint sensor and manufacturing method thereof

A technology of a fingerprint sensor and a manufacturing method, which is applied in the acquisition/organization of fingerprints/palmprints, instruments, identification devices, etc., can solve the problem of poor human-computer interaction experience, affecting the accuracy of fingerprint identification, and inability to effectively penetrate the display module, etc. problems, to avoid the inconvenience of operation, the display effect is excellent, and the product is beautiful and elegant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

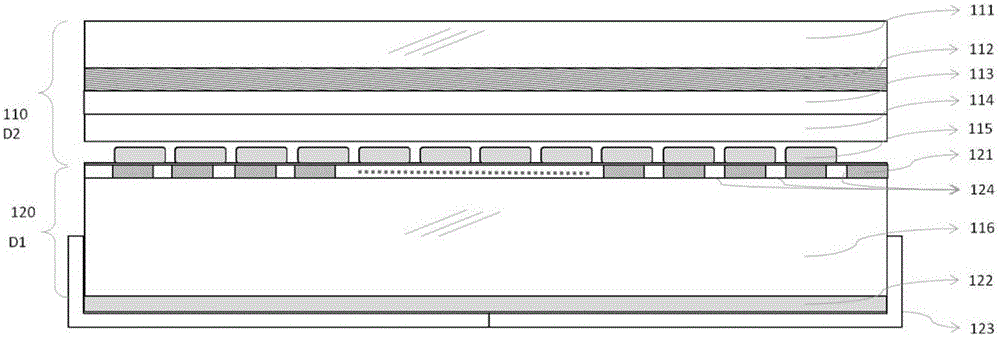

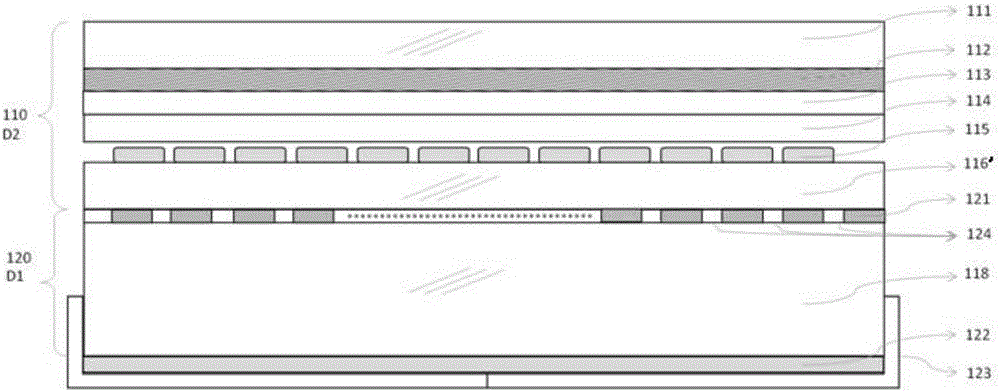

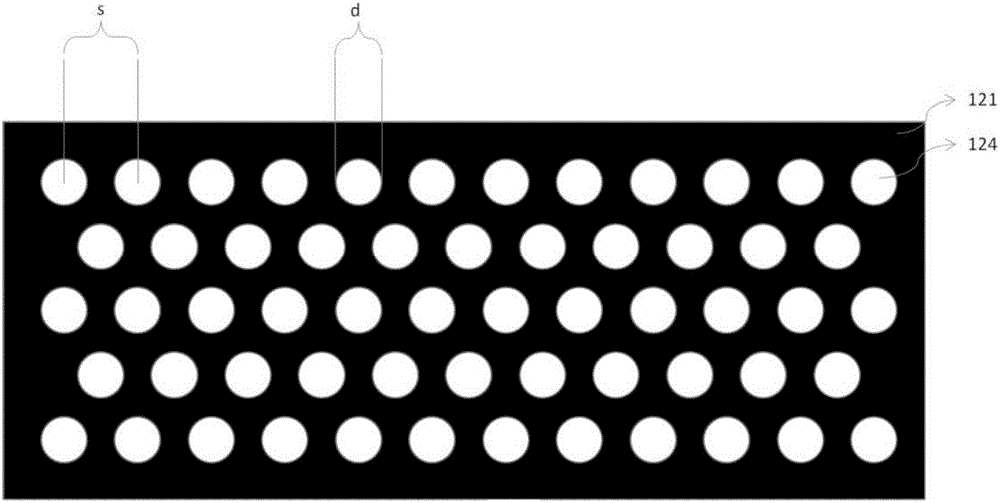

[0089] figure 1 It is a schematic structural diagram of a single-layer substrate display supporting a full-screen optical fingerprint sensor, and its process is a single-layer substrate process.

[0090] The LED display module 110 (ie, the display module) includes a cover glass 111 , a CTP capacitive touch sensor 112 (ie, the touch sensor 112 ), a polarizer 113 , a package cover 114 , an LED pixel circuit 115 , and a substrate 116 . The CTP capacitive touch screen is integrated in the display screen, and it can also be installed under the cover glass. Each layer is bonded by optical glue OCA to improve light transmittance.

[0091] In order to support high light transmittance, the substrate 116 may be a transparen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com