A kind of capacity division method of high-voltage lithium-ion battery

A lithium-ion battery and capacity-division technology, which is applied in secondary batteries, electrolyte battery manufacturing, non-aqueous electrolyte batteries, etc., to achieve the effects of eliminating insufficient power supply, stable voltage and slow decay.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

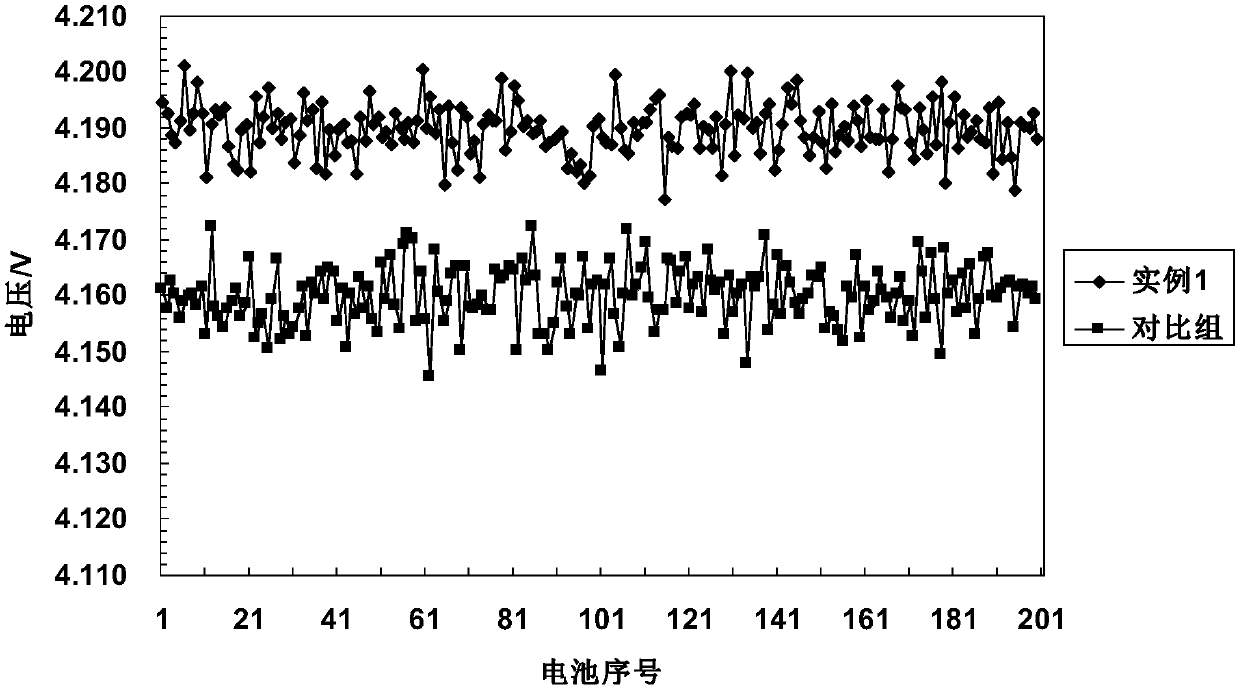

Image

Examples

Embodiment 1

[0026] A kind of capacity dividing method of high-voltage lithium-ion battery, its concrete steps are as follows:

[0027] a. The first charging stage: take the formed battery, charge it to 4.2V with a current of 0.5C constant current and constant voltage, the cut-off current is 0.02C, the time limit is 130min, and stand for 5min;

[0028] b. Discharge stage: Discharge to 3.0V at a constant current of 0.5C, the time limit is 130min, and stand for 5min;

[0029] c. The second charging stage: charge to 4.2V with a current of 0.5C constant current and constant voltage, the cut-off current is 0.02C, the time limit is 200min, and stand for 60min;

[0030] d. The third charging stage: first charge to 4.21V with a current of 0.5C constant current and constant voltage, the cut-off current is 0.02C, the time limit is 60min, and stand for 60min; then charge to 4.22V with a current of 0.5C constant current and constant voltage V, the cut-off current is 0.02C, the time limit is 60min, an...

Embodiment 2

[0033] A kind of capacity dividing method of high-voltage lithium-ion battery, its concrete steps are as follows:

[0034] a. The first charging stage: take the formed battery, charge it to 4.0V with a current of 0.05C constant current and constant voltage, the cut-off current is 0.02C, the time limit is 150min, and stand for 5min;

[0035] b. Discharge stage: discharge to 3.0V at a constant current of 0.05C, the time limit is 150min, and stand for 5min;

[0036] c. The second charging stage: charge to 4.2V with a current of 1.0C constant current and constant voltage, the cut-off current is 0.02C, the time limit is 180min, and stand for 60min;

[0037] d. The third charging stage: first charge to 4.21V with a current of 0.05C constant current and constant voltage, the cut-off current is 0.02C, the time limit is 120min, and stand for 60min; then charge to 4.22V with a current of 0.5C constant current and constant voltage V, the cut-off current is 0.02C, the time limit is 60min...

Embodiment 3

[0040] A kind of capacity dividing method of high-voltage lithium-ion battery, its concrete steps are as follows:

[0041] a. The first charging stage: take the formed battery, charge it to 4.2V with a current of 0.05C constant current and constant voltage, the cut-off current is 0.02C, the time limit is 150min, and stand for 5min;

[0042] b. Discharge stage: discharge to 3.0V at a constant current of 0.05C, the time limit is 180min, and stand for 5min;

[0043] c. The second charging stage: charge to 4.2V with a current of 0.5C constant current and constant voltage, the cut-off current is 0.02C, the time limit is 200min, and stand for 60min;

[0044]d. The third charging stage: first charge to 4.21V with a current of 0.05C constant current and constant voltage, the cut-off current is 0.02C, the time limit is 120min, and stand for 60min; V, the cut-off current is 0.02C, the time limit is 120min, and the time is limited to 60min; first charge to 4.23V with a current of 0.5C c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com