Rail wheels and rail vehicles

A wheel and track technology, applied in the field of rail wheels, to achieve the effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

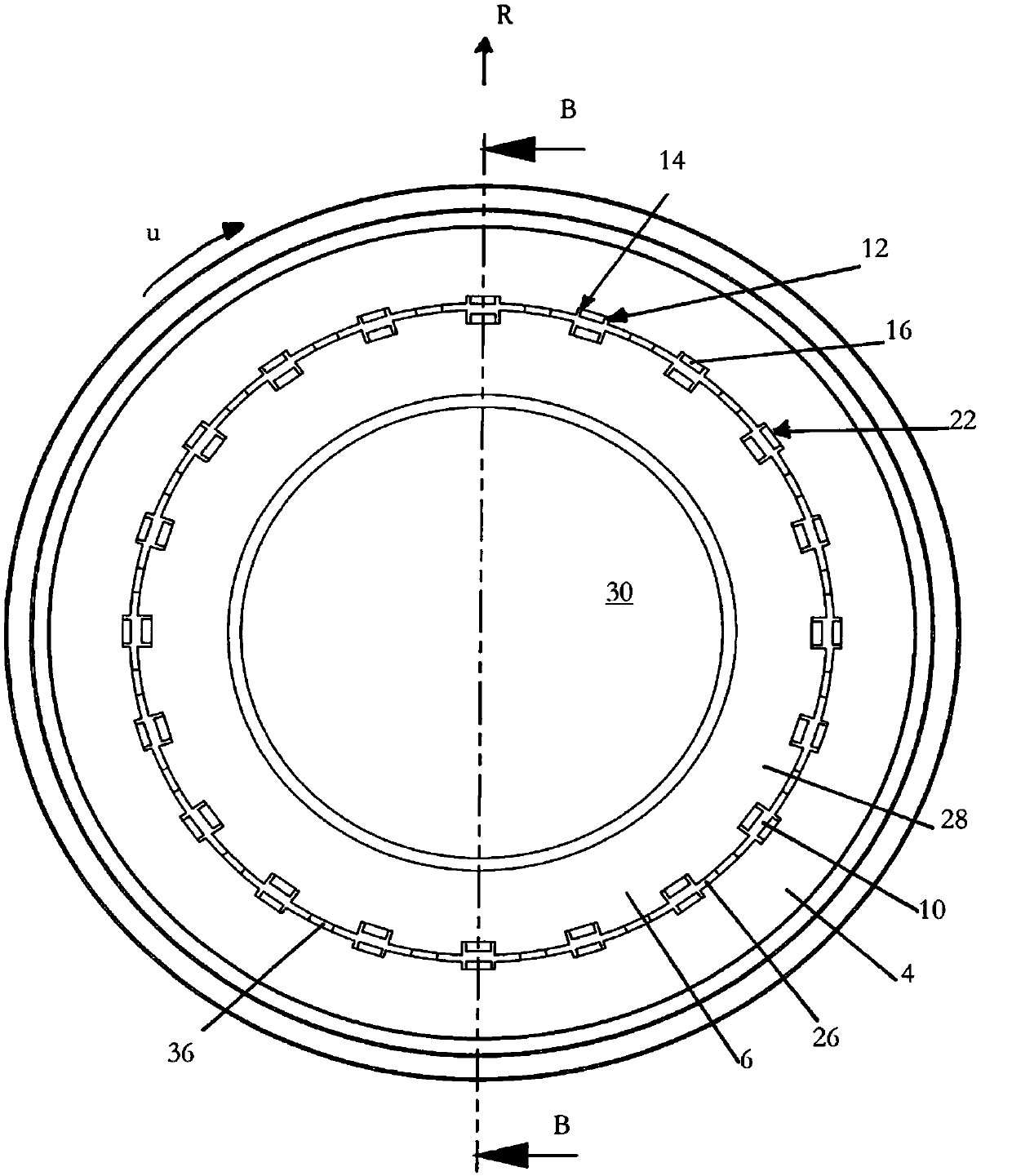

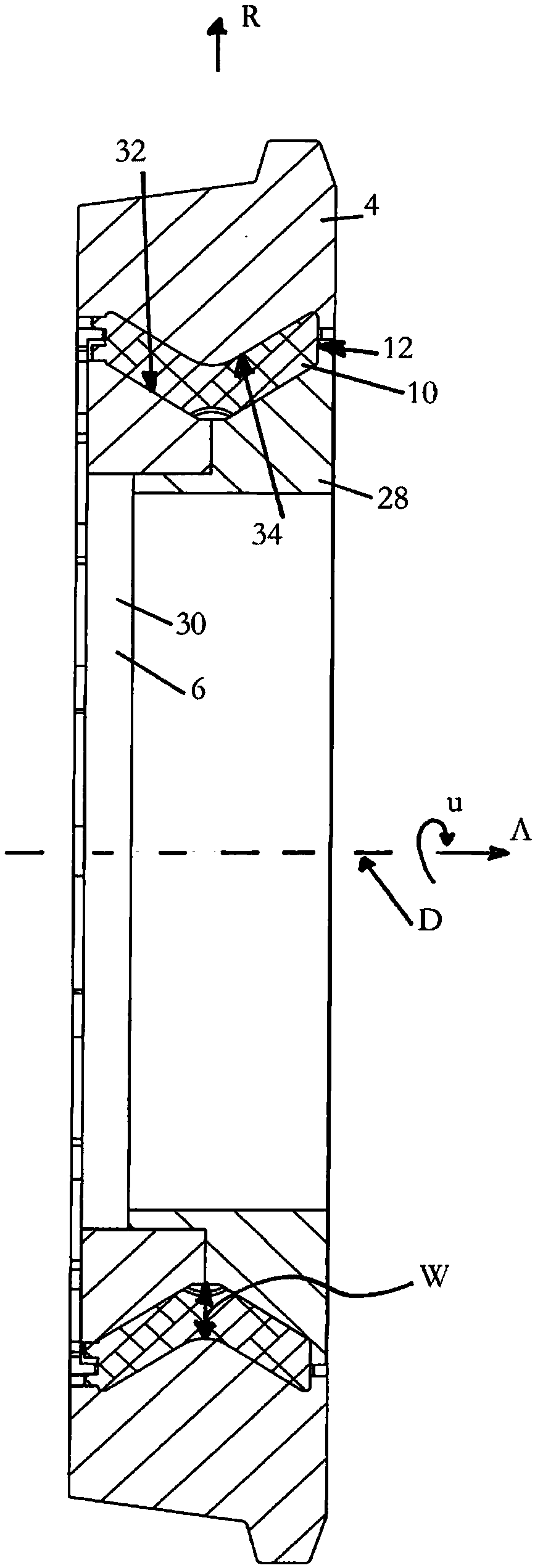

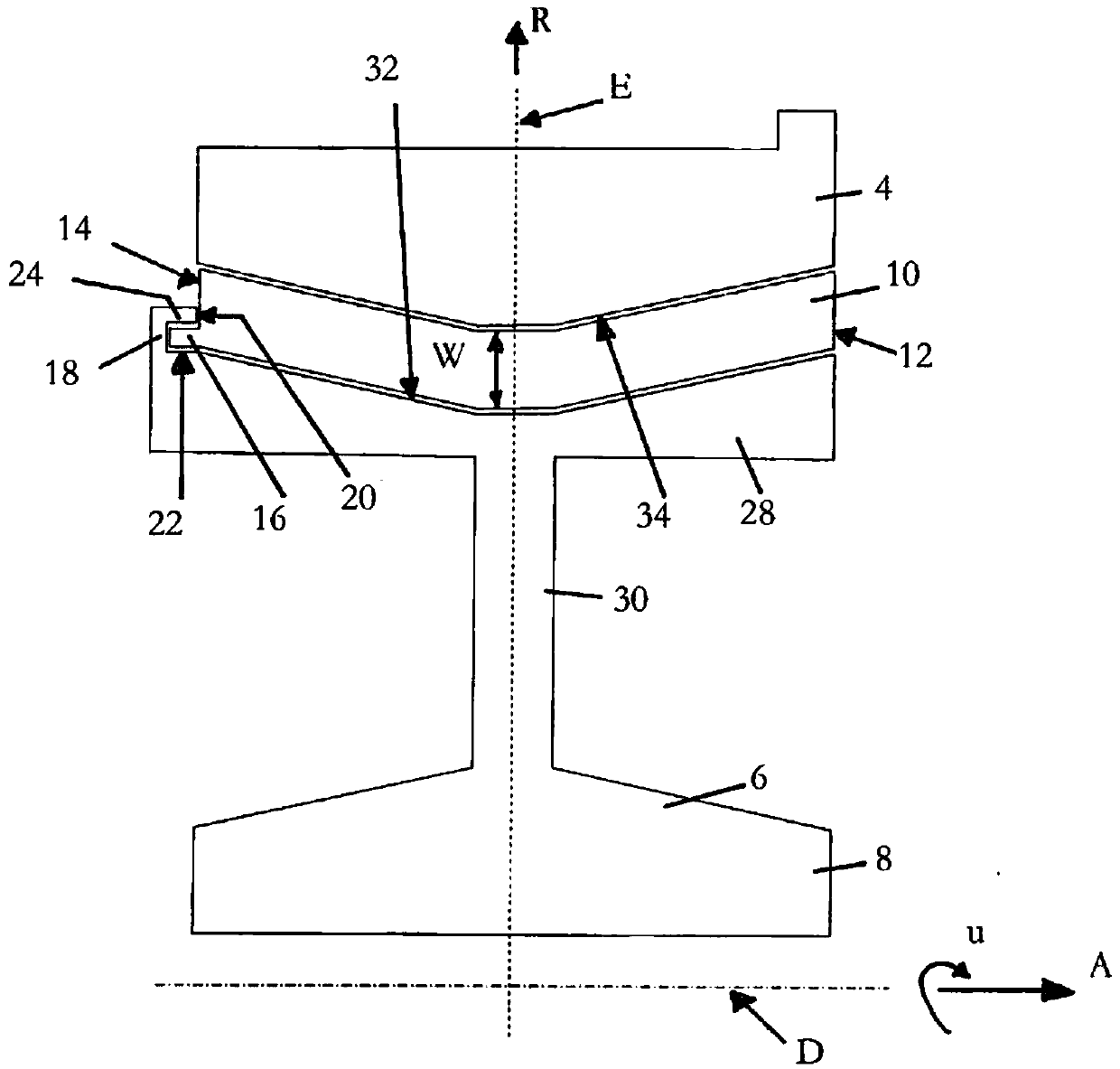

[0028] exist figure 1 shows a rail wheel 2 according to the invention in a schematic side view. The rail wheel 2 comprises an annular tire 4 arranged radially on the outside. In addition, the cylindrical wheel body 6 is arranged radially on the inside. Since the tire 4 and the wheel body 6 are arranged coaxially with each other, an annular gap is formed between the tire 4 and the wheel body 6 . The spring body 10 is inserted into the annular gap. The spring body 10 is used for force transmission in the radial direction R and for torque transmission.

[0029] figure 2 is shown in a cross-sectional view along section B-B from figure 1 The track wheels 2. Therefore, the following description refers to the figure 1 and figure 2 the summary of. It has proven to be advantageous in practice if the spring body 10 is V-shaped in cross-section. In order to be able to arrange the spring body 10 between the wheel body 6 and the tire 4 , the wheel body 6 is preferably formed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com