Solid-tire-and-rim composite structure

A solid tire, combined structure technology, used in tire parts, non-pneumatic tires, transportation and packaging, etc., can solve problems such as melting and cracking of rubber materials, and achieve the effect of weakening radial rigidity and improving ride comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

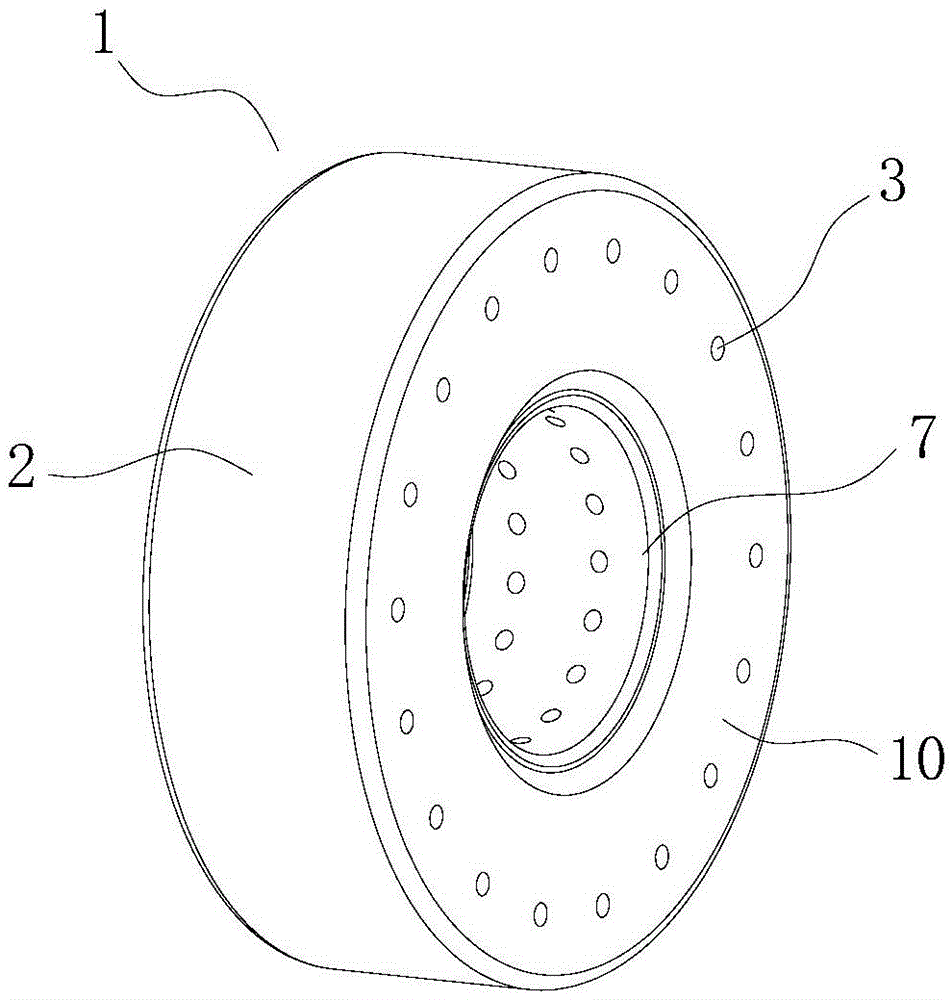

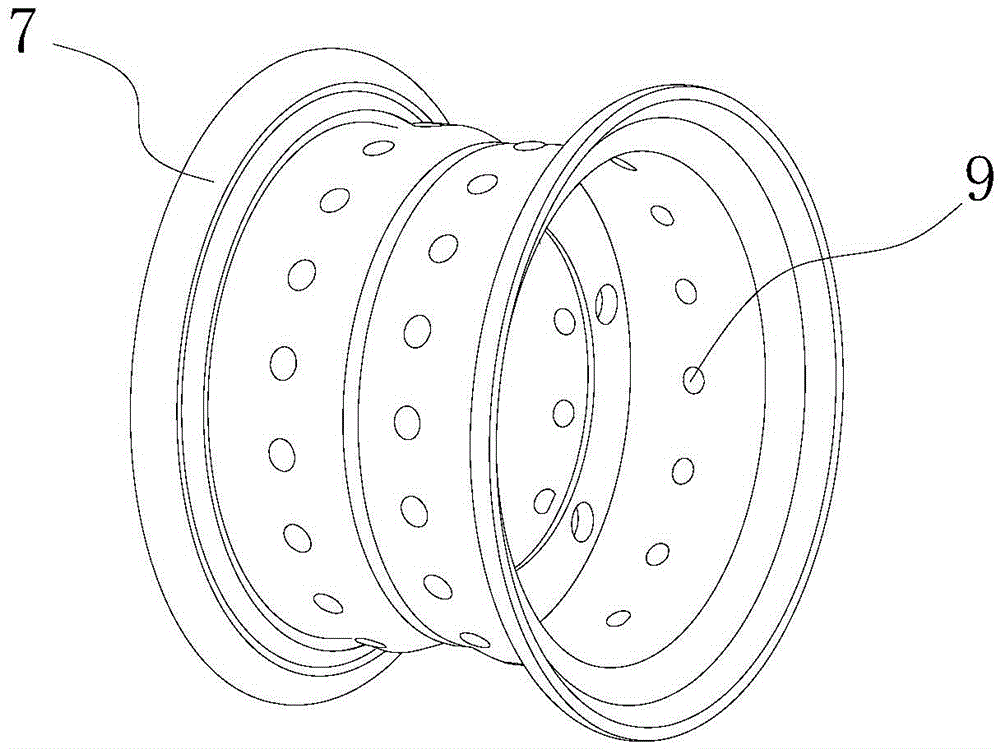

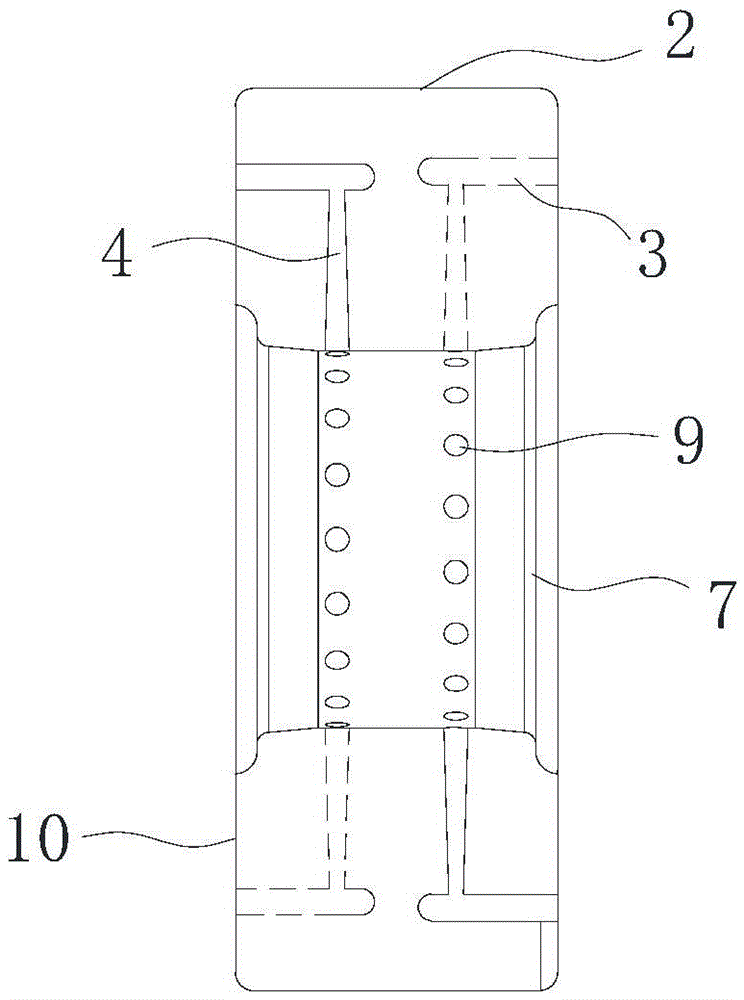

[0024] Such as Figure 1 to Figure 5 As shown, the present invention provides a solid tire and rim combined structure, which includes a tire 1, a rim 7 for fixing the tire 1, and a wire ring 6 in the tire 1, wherein the tire 1 is divided into a tread portion 2, a tire on both sides The bead portion 10 and the bead portion 5 in contact with the rim 7 are provided with a plurality of axial cooling holes 3 and radial cooling holes 4 on the tire carcass, wherein the axial cooling holes 3 are distributed on the bead portion 10 and along the tire The axial direction extends into the carcass, and the radial cooling hole 4 extends along the radial direction of the tire to the axial direction. The radial cooling hole 4 is connected with the axial cooling hole 3 to form a "7-shaped" through hole. Rigidity, improve the heat dissipation performance of the tire, so as to ensure the service life of the tire.

[0025] See Figure 4 As shown, the diameter φR of the axial cooling hole 3 shou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com