Loading device and loading method for dynamic biaxial compression of solid propellant

A technology of solid propellants and loading devices, which is applied to measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve problems such as inability to test biaxial mechanical properties of materials, and achieve uniform and universal load distribution Good performance, reduce the effect of prestress and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

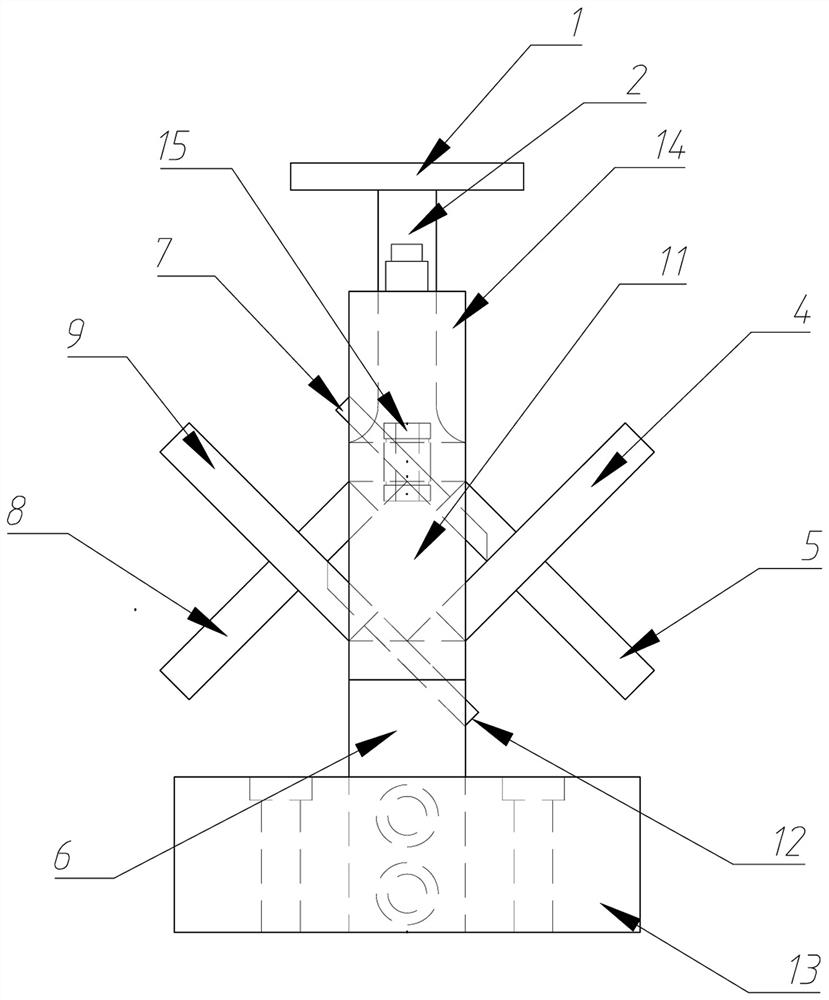

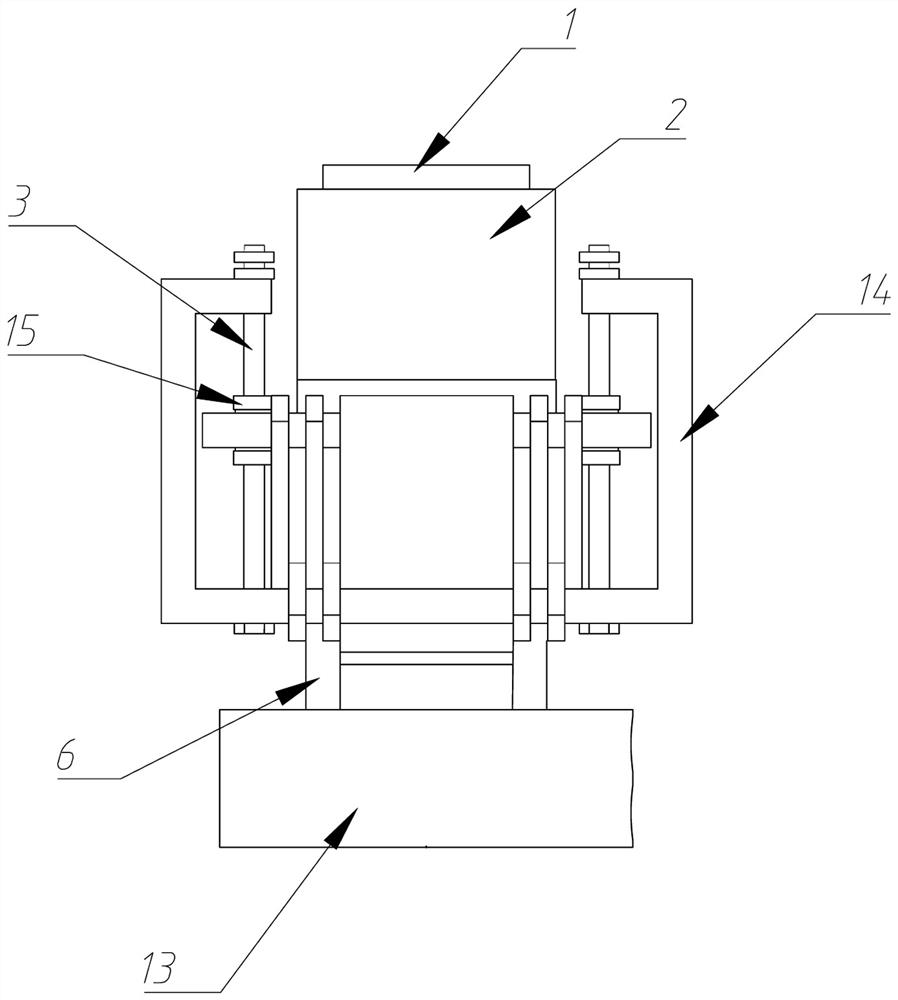

[0052] The present invention is a loading device for dynamic biaxial compression of solid propellant, which comprises an upper clamp and a lower clamp which are matched and connected. A disc-shaped upper pressure plate 1 is fixedly connected to the upper loading table 2;

[0053] The lower clamp includes a lower clamp body and a lower loading platform 6 fixedly arranged at the lower end of the lower clamp body, and a bottom fixed sleeve 13 is fixedly connected to the lower loading platform 6;

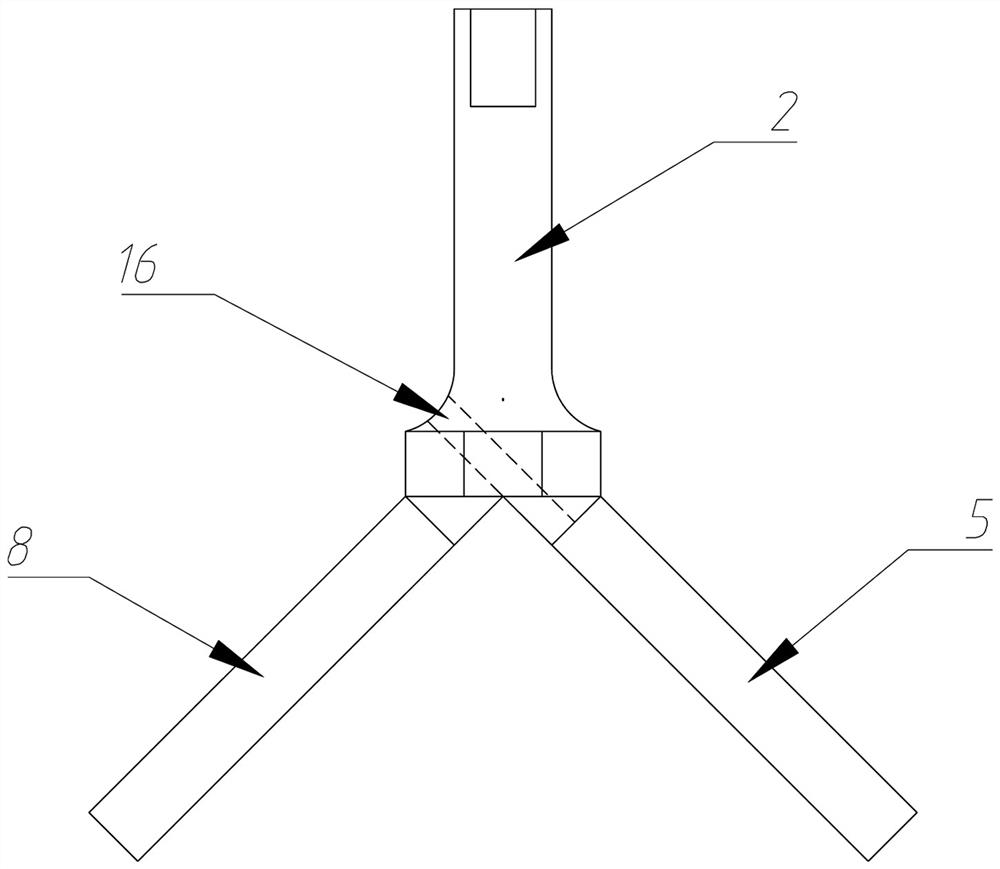

[0054] The upper clamping body and the lower clamping body are fastened to each other, and the area between the upper clamping body and the lower clamping body is the clamping area 11. The clamping area 11 is in the shape of a cuboid, and the diagonal line of the clamping area 11 is located One of the planes is parallel to the vertical plane; a guiding device is also arranged between the upper clamping body and the lower clamping body;

[0055] The two ends of the upper clamping body a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com