Double disc coulter

A double-disc and disc plow technology, which is applied to plows, agricultural machinery and tools, and digging/covering trenches and holes, can solve the problems of inaccurate modeling, expensive, troublesome mass production, etc., and achieve the effect of easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

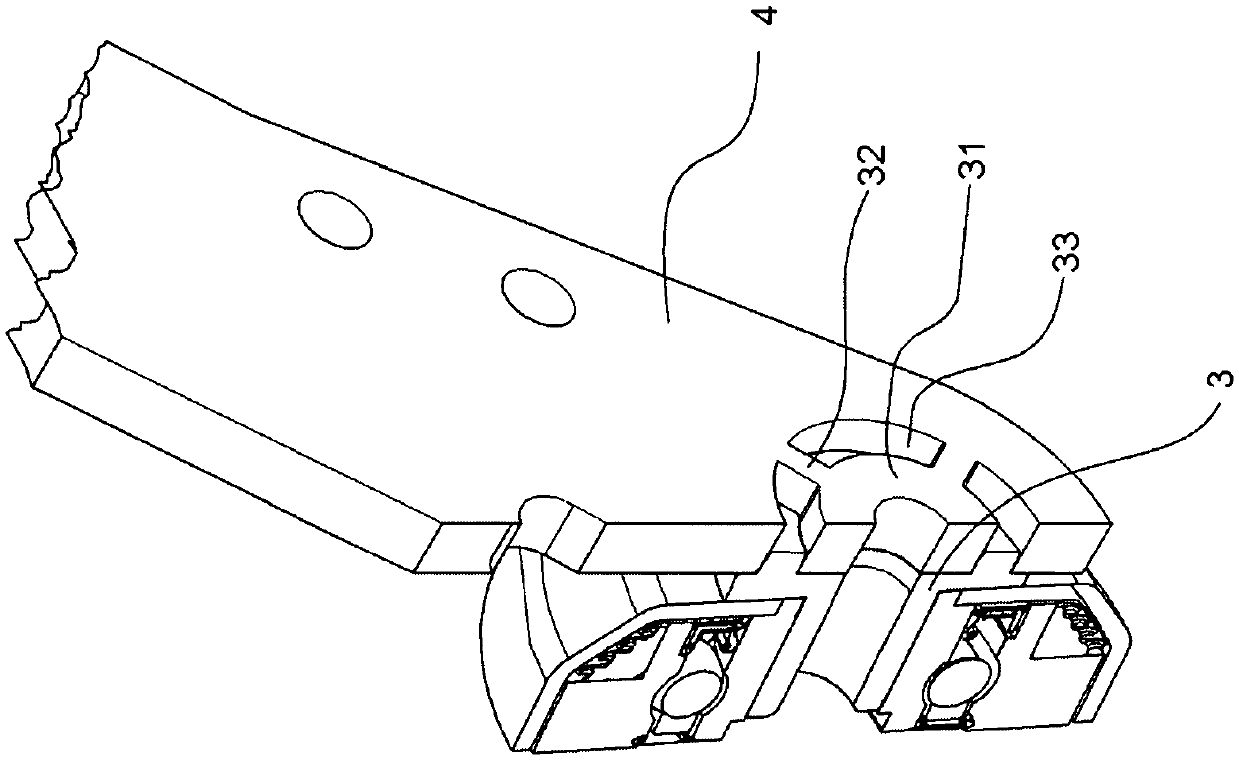

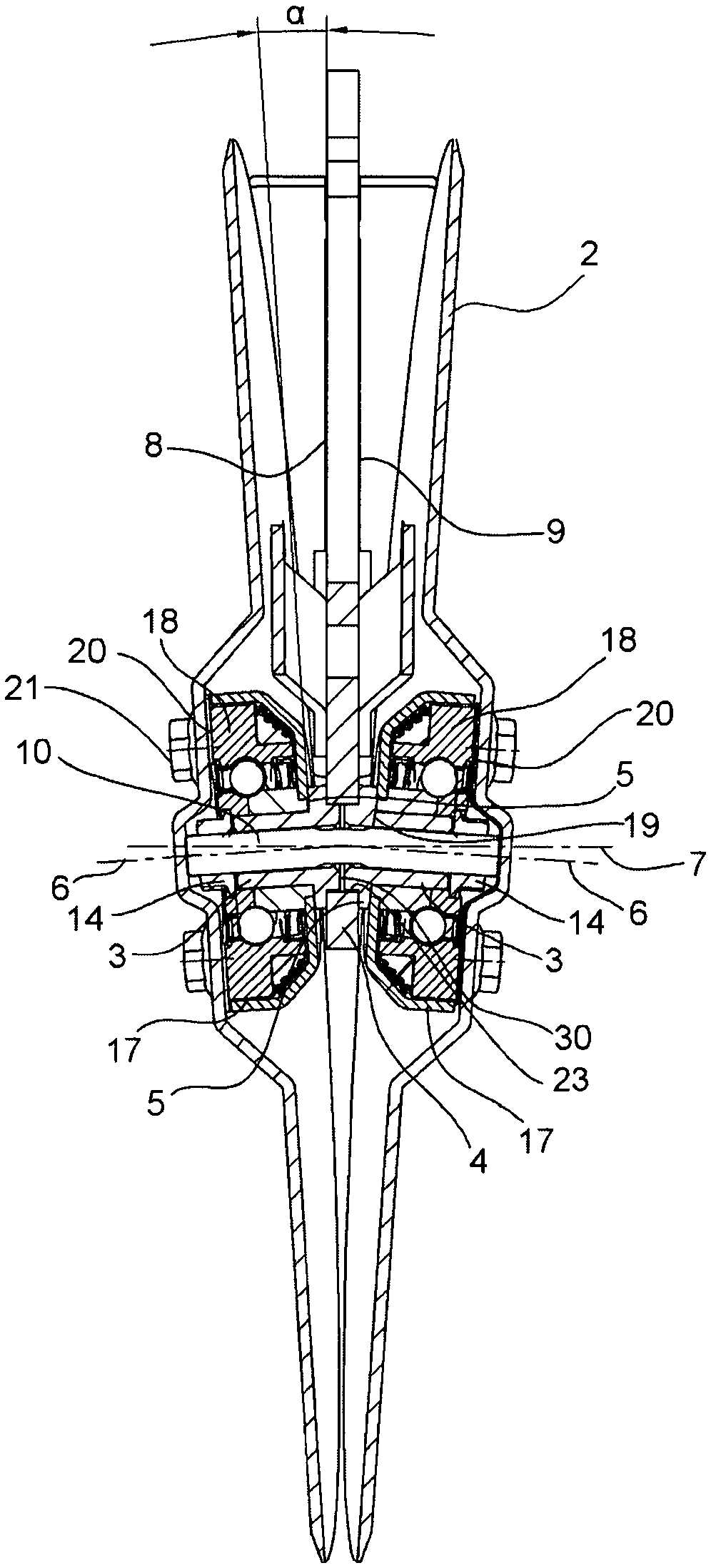

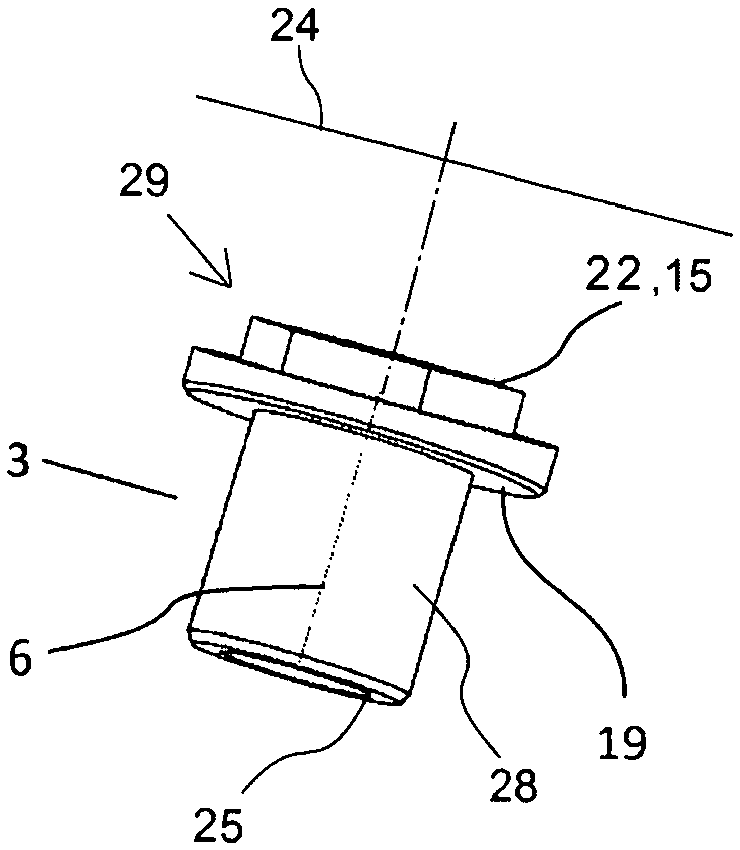

[0027] figure 1 A cross-sectional view of a double disc coulter is shown in perspective. The right-hand coulter disc is not shown for a better view of the coulter holder. The double-disc coulters 1 are connected laterally at a distance from other double-disk coulters (not shown) by means of a front borehole 11 in such a way that they can move vertically on the crossbeam by means of bearing elements , and the beam is connected with the main frame (Hauptrahme) of the distribution machine (Verteilmaschine). A vertical, movably connected post 12 to the coulter bar can exert pressure on the coulter bar 4 and the double disc coulter 1 with respect to the base by means of a spring or other force , so that it squeezes into the soil. Due to the V-shaped position of the disk coulters relative to one another, the soil is pushed apart in a V-shaped manner. The agricultural product can be introduced into this V-groove by means of an application line (Ausbringleitung) which protrudes in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com