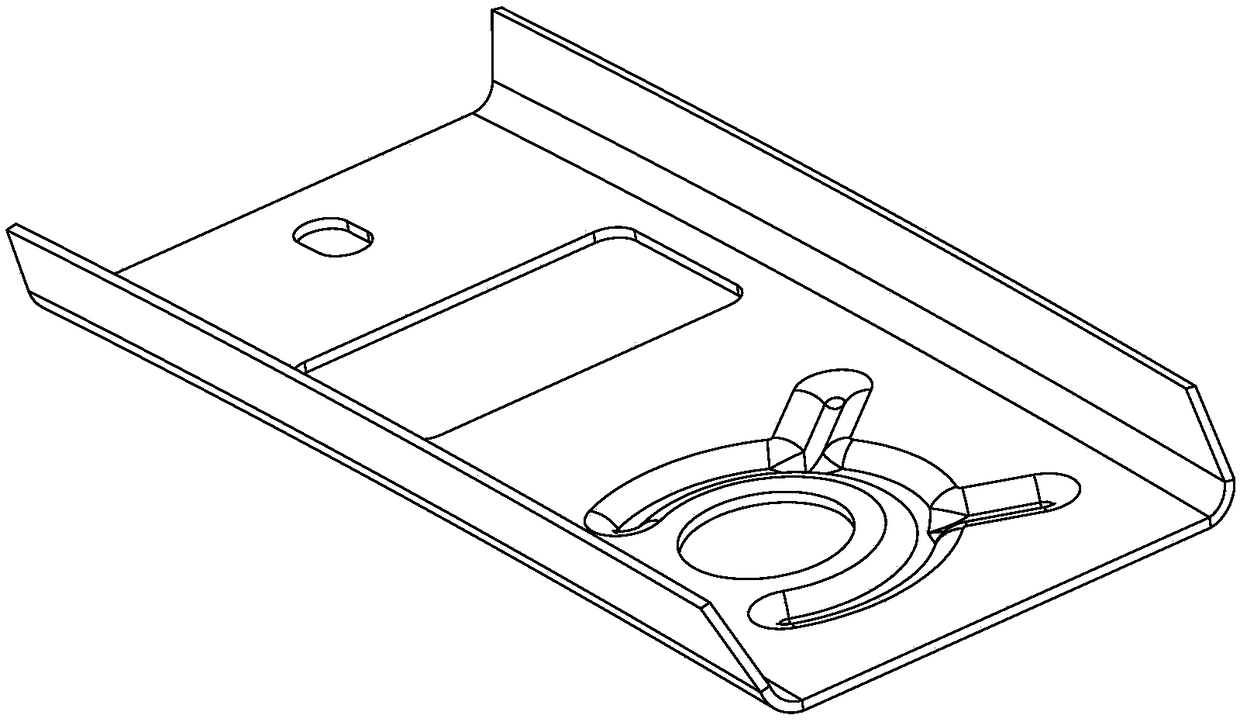

Car bumper accessory progressive die

An automobile bumper and accessory-level technology, which is applied in the field of automobile bumper accessories progressive die, can solve the problems of increasing defective products, time-consuming, operator injury, etc., and achieves the effect of saving equipment space, accurate processing, and reducing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

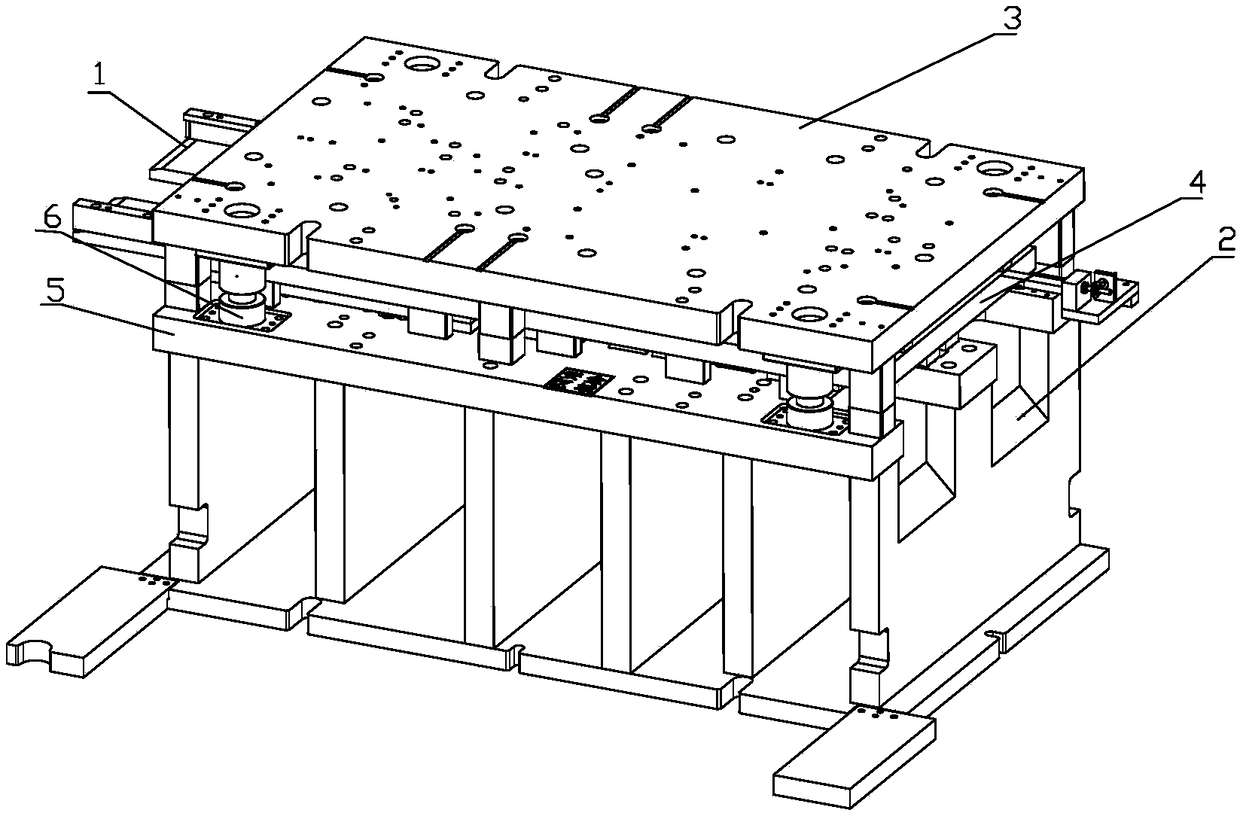

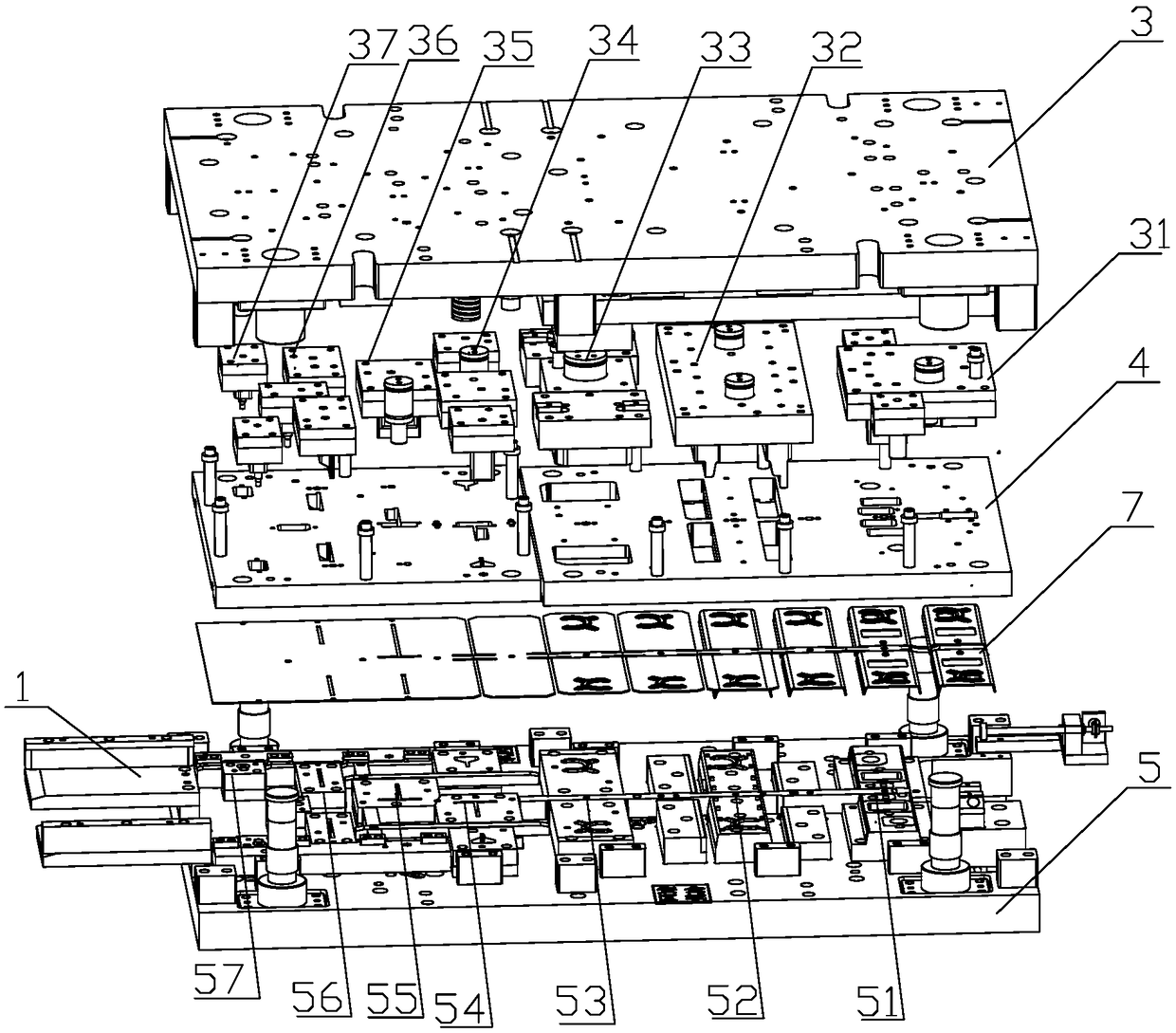

[0025] The present invention will be described in further detail below in combination with the accompanying drawings, and specific implementation methods will be given.

[0026] Such as Figure 2-8 Shown, a kind of progressive die of automobile bumper fittings, comprises the upper mold fixed plate 3 that is used to fix the upper mold, the binder plate 4 that is arranged from top to bottom and the lower mold fixed plate 5 that is used to fix the lower mold, so Said patrix comprises successively the die 33 for processing C-shaped reinforcing ribs, the flanging molding die 32, the large hole punching die 31 according to the processing procedure, and said die 33 is positioned at the middle part of the lower surface of the patrix fixed plate 3, and the large hole punching die 31 is located on one side of the upper die fixing plate 3, and the flanging forming die 32 is located between the die 33 and the large hole punching die 31;

[0027] The binder plate 4 is flexibly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com