Elastic foil piece bearing top layer foil piece heat treatment tool capable of controlling shape and performance

An elastic foil and tooling technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of reducing the corrosion resistance and mechanical fatigue properties of the foil, increasing the processing cost, and scrapping the foil, so as to curb the degree of surface oxidation. , Prevent surface oxidation, good fit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

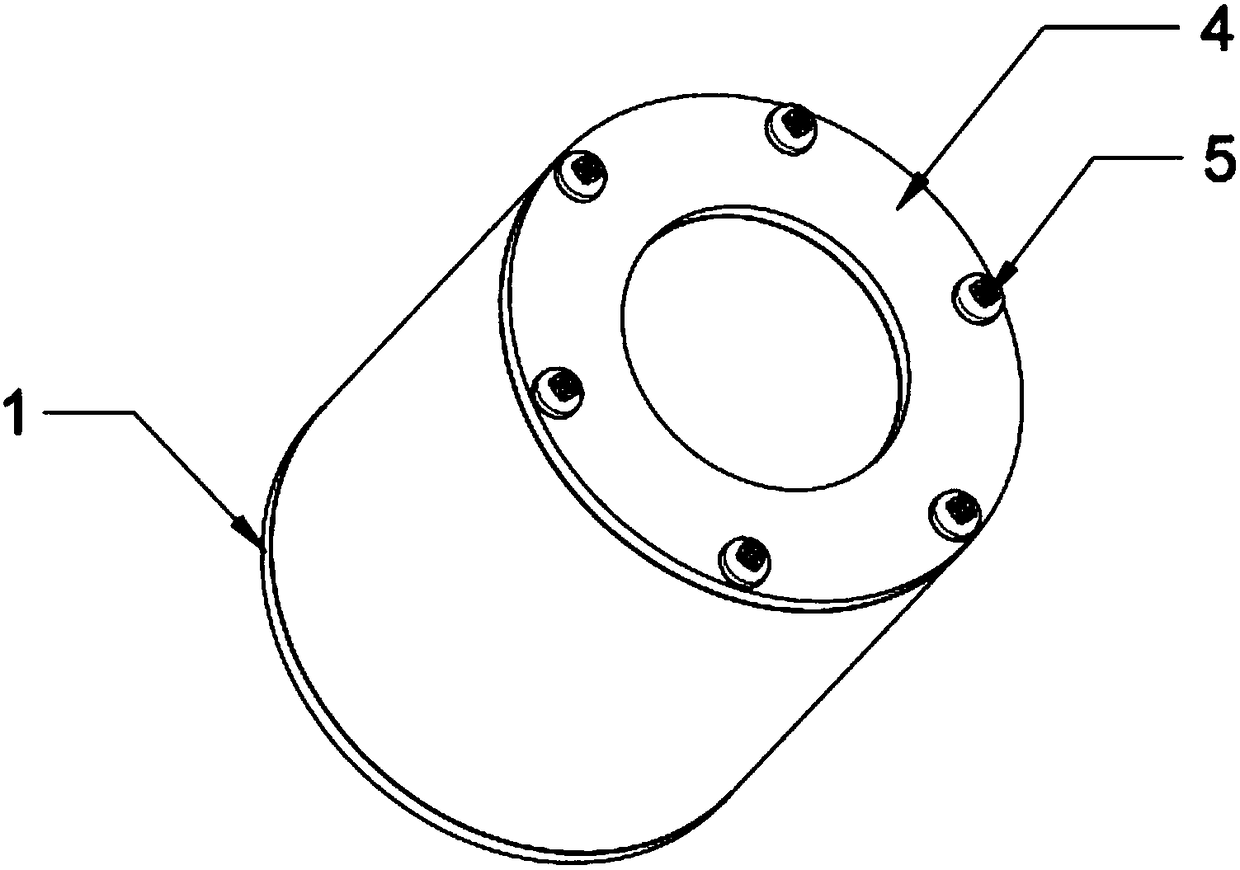

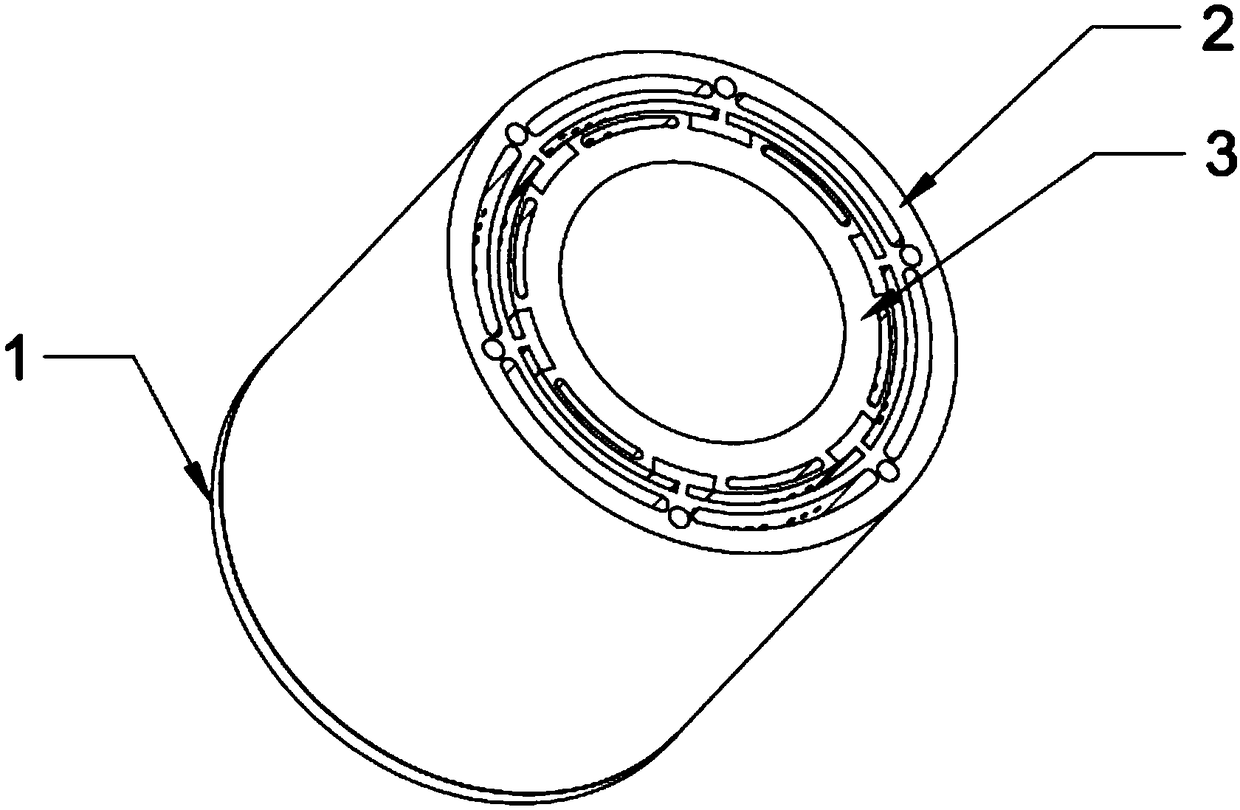

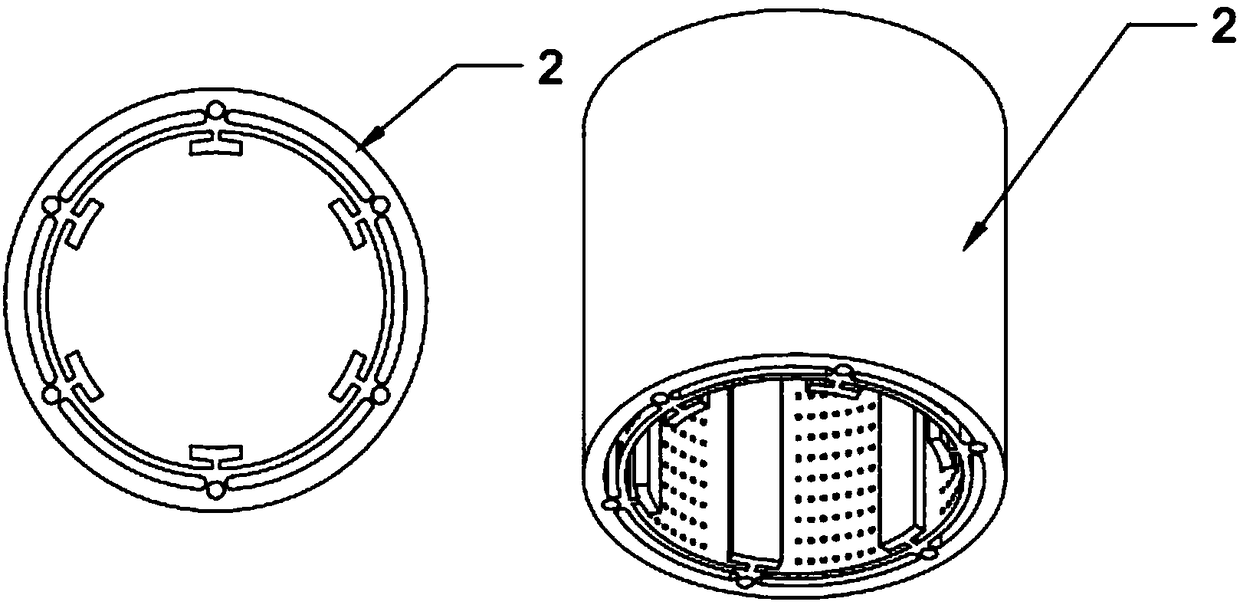

[0017] Such as figure 1 , figure 2 As shown, a controllable shape-controllable elastic foil bearing top layer foil heat treatment tooling includes an inner mold 3, and the inner mold 3 is loaded into the outer mold 2 through the slot matched with the outer mold 2, and forms with the outer mold 2 A plurality of through slots capable of placing elastic foils, the two ends of the inner mold 3 and the outer mold 2 are provided with a bottom cover 1 and a top cover 4, and the bottom cover 1 and the top cover 4 are fixed on the outer mold by fastening screws 5 2 above; during the heat treatment process, the elastic foil is inserted into the through groove formed by the outer mold 2 and the inner mold 3 to form a predetermined curvature, which can be fixed after the heat treatment to achieve the effect of shape control. The curvature radius of the through groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com