Large-capacity optical cable cross-connecting cabinet capable of longitudinally expanding without disassembling

A fiber optic cable transfer box and large-capacity technology, applied in the direction of light guides, optics, optical components, etc., can solve the problems of reducing maintenance efficiency, reducing space utilization, and the impact of the surrounding space of the box, so as to facilitate installation and later maintenance , Improve space utilization and ensure the effect of curvature radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

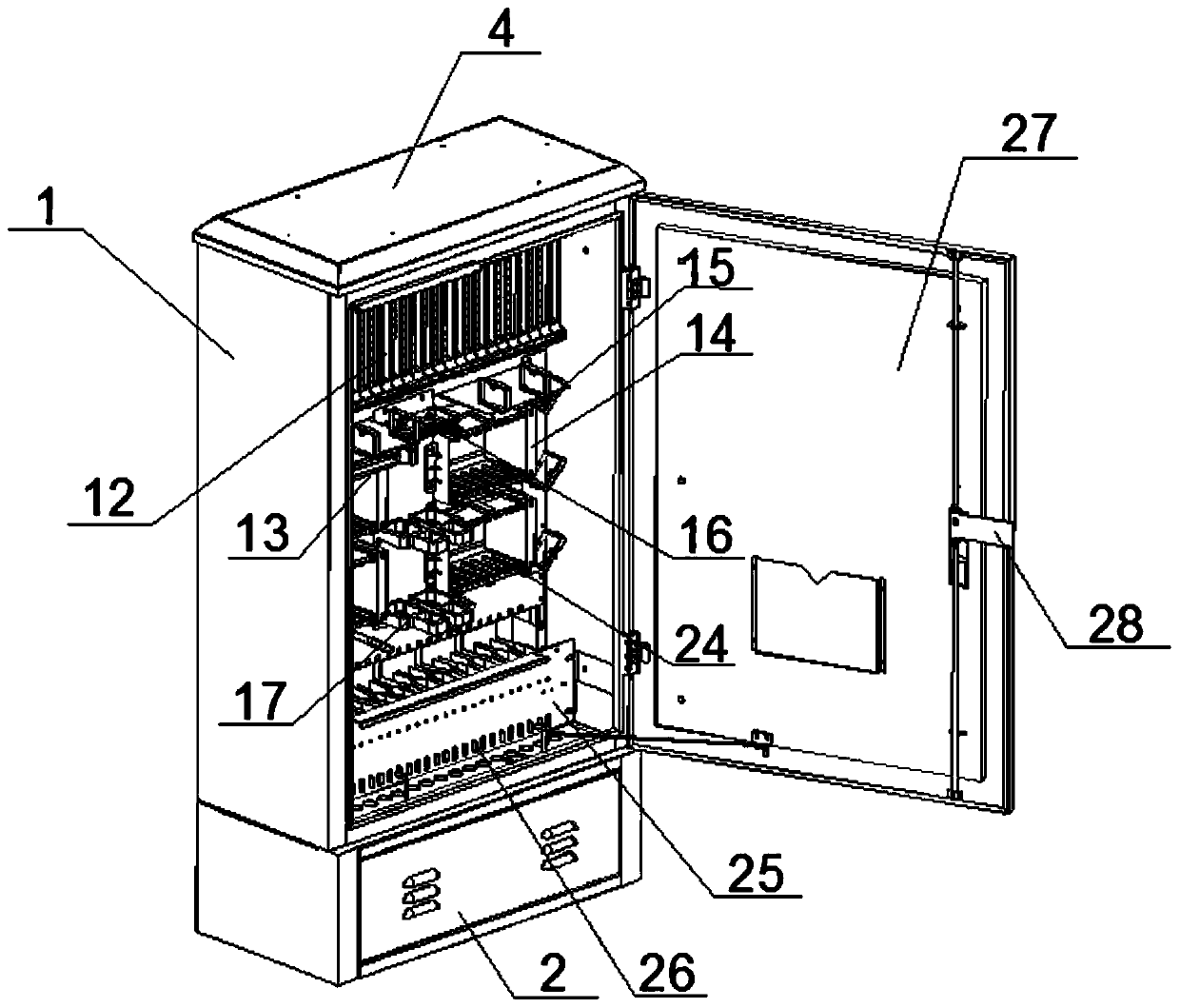

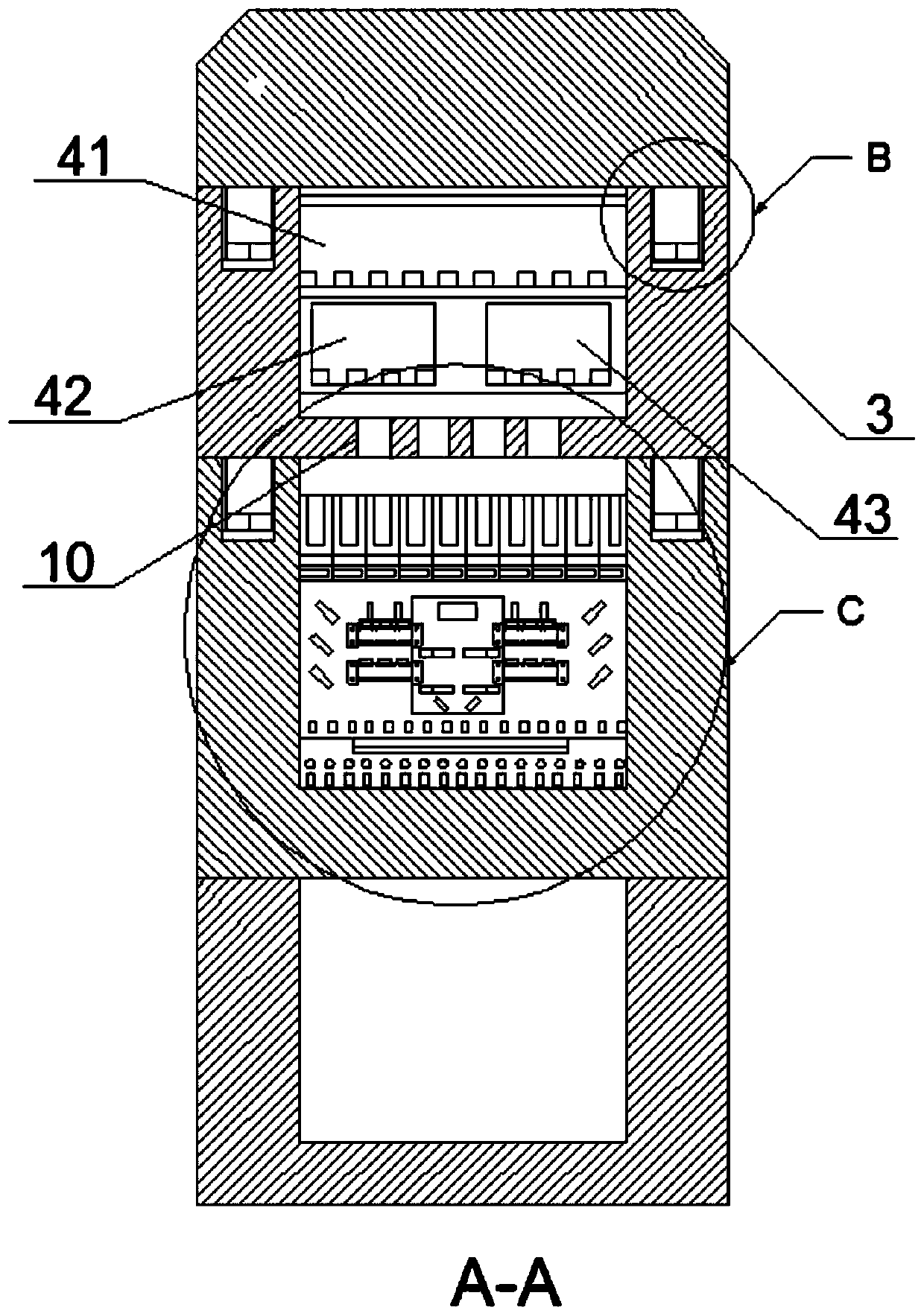

[0033] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0034] The existing technology is to use the horizontal expansion method to expand the capacity of the optical cable transfer box. The specific construction steps are as follows: the first step is to remove the optical cable landing transfer box, including on-site cleaning of the existing optical transfer box usage, and to formulate a box disassembly plan (to ensure No failure to the in-use business), on-site dismantling and other workloads; the second step, the installation of the floor-type transfer box base includes the measurement of the site terrain, and the removal, expansion, and transformation of the original base according to the new box size. The third step is to install the optical cable landing transfer box, which includes the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com