Process for the production of acetic acid

A technology of acetic acid and methyl acetate, applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, preparation of carboxylate, etc., can solve problems such as reducing the efficiency of carbon monoxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

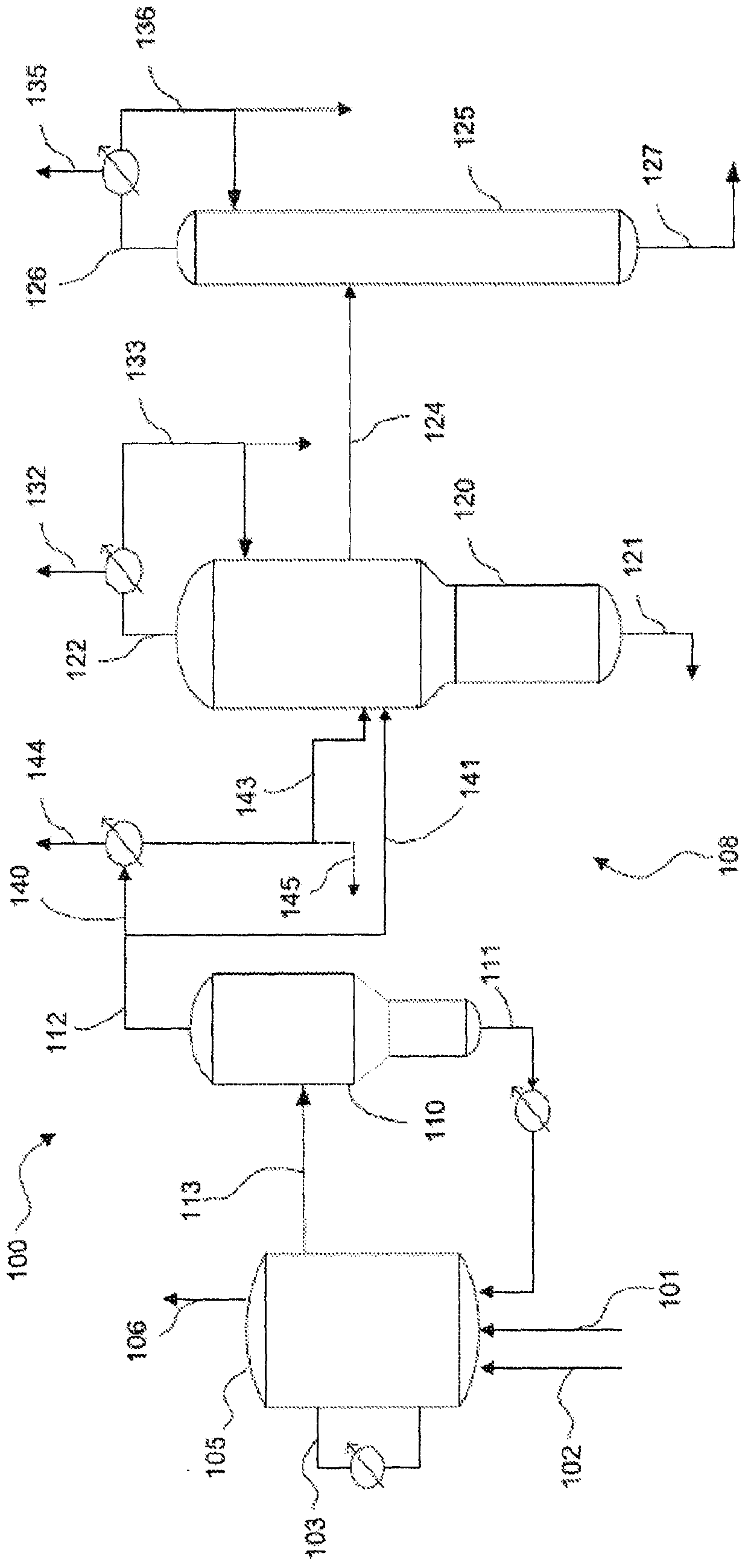

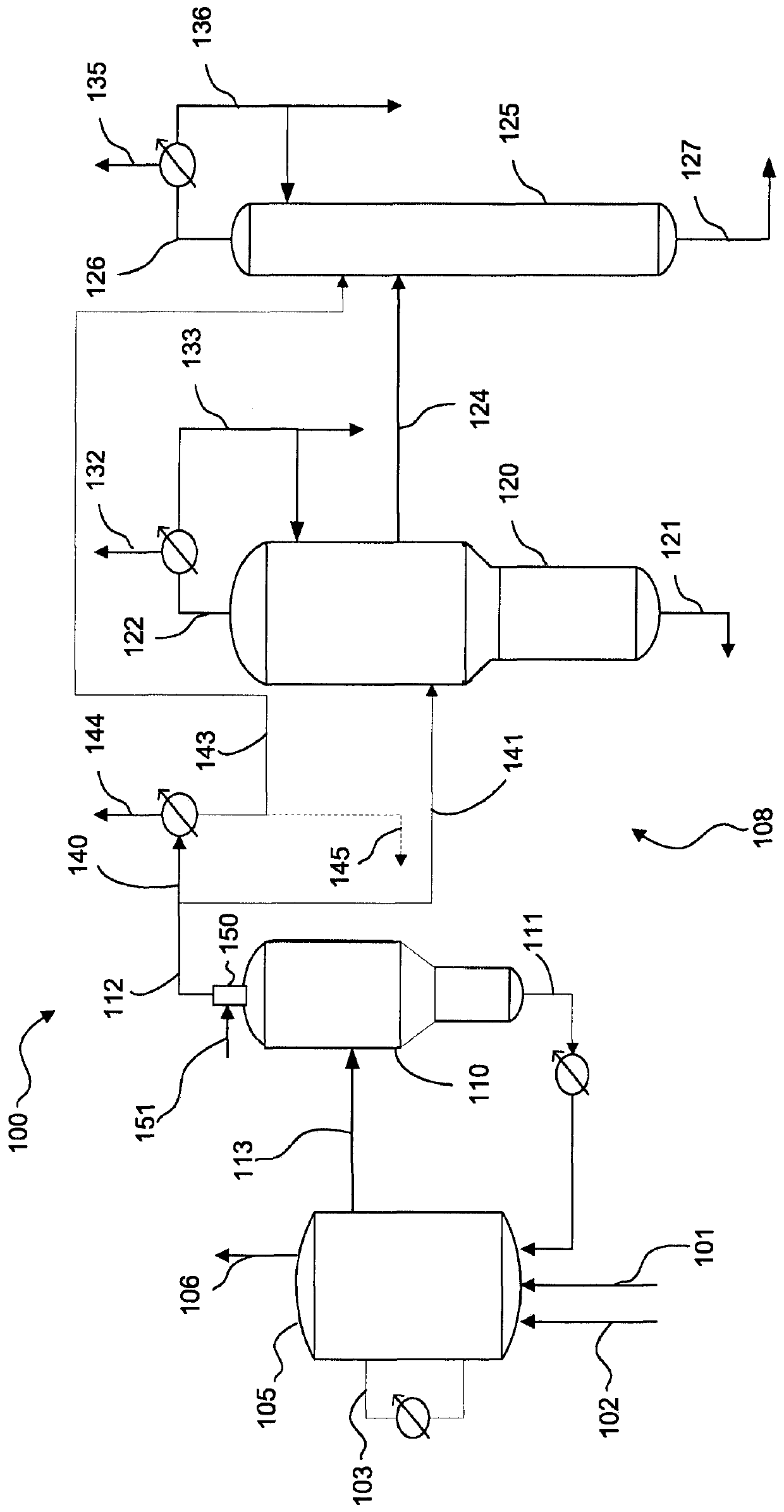

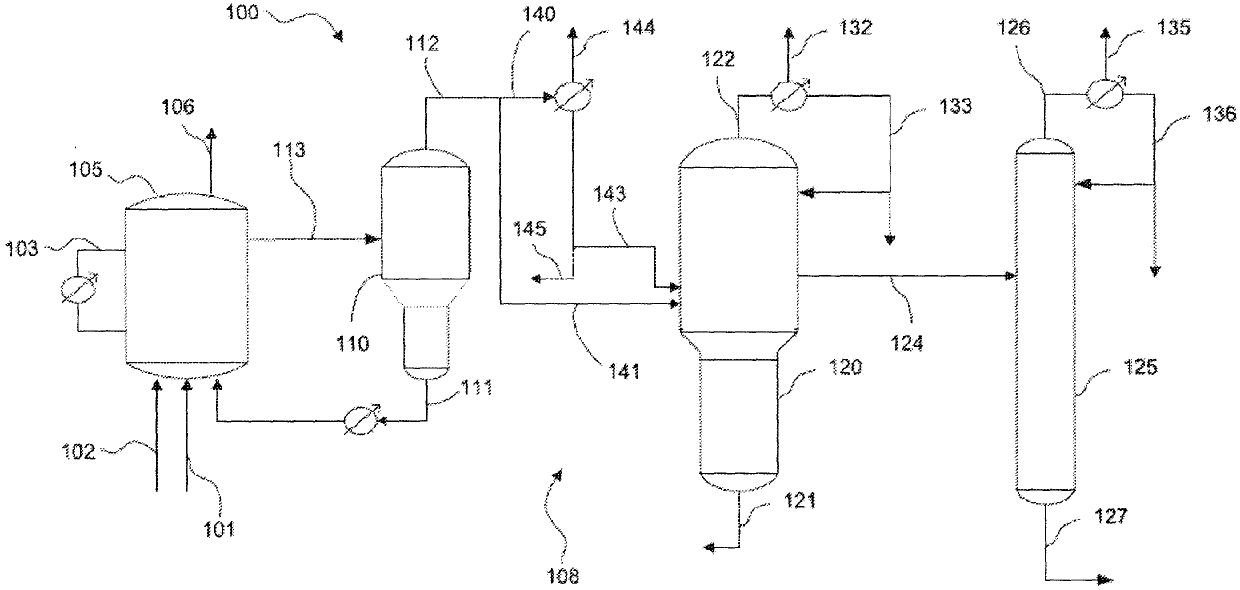

Image

Examples

Embodiment approach

[0120] E1. A method for producing acetic acid, said method comprising:

[0121] In the reactor, in the presence of 0.1% to 14% by weight of water, metal catalysts, methyl iodide and iodide salts, at least one selected from the group consisting of methanol, dimethyl ether, methyl acetate and mixtures thereof carbonylation of a reactant to form a reaction medium;

[0122] splitting the reaction medium into a liquid recycle and a vapor product stream comprising acetic acid, methyl iodide, methyl acetate and water;

[0123] condensing a first portion of the vapor product stream to form a liquid stream; feeding a second portion of the vapor product stream to the first column;

[0124] feeding at least a portion of the liquid stream to the first column; and

[0125] A side stream containing acetic acid product is drawn from the first column.

[0126] E2. The process of embodiment E1, wherein 1% to 50% by weight of the vapor product stream is condensed to form a liquid stream, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com