Cyperus esculentus harvester and threshing device

A threshing device and the technology of oily bean, which can be applied in the direction of excavator, harvester, threshing equipment, etc., can solve the problem of inability to separate the oily bean.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

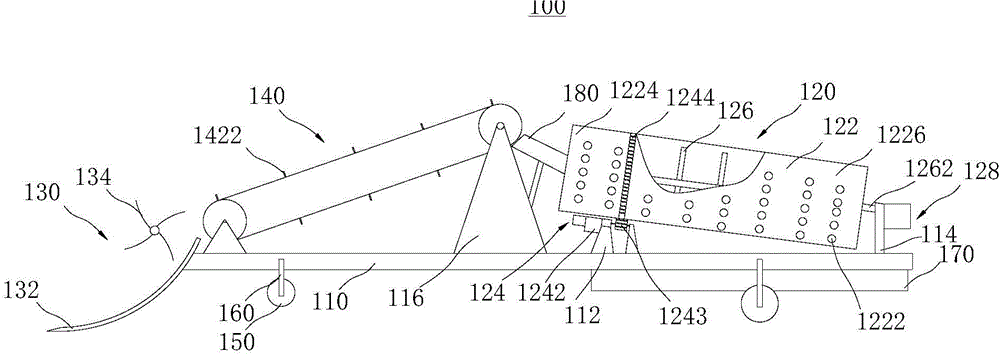

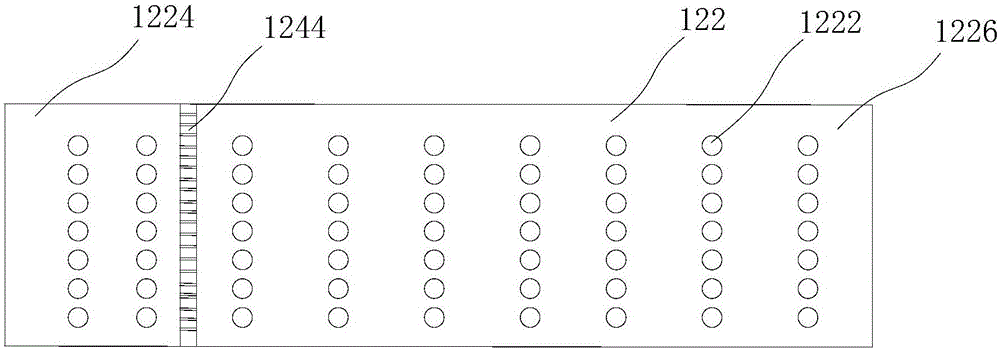

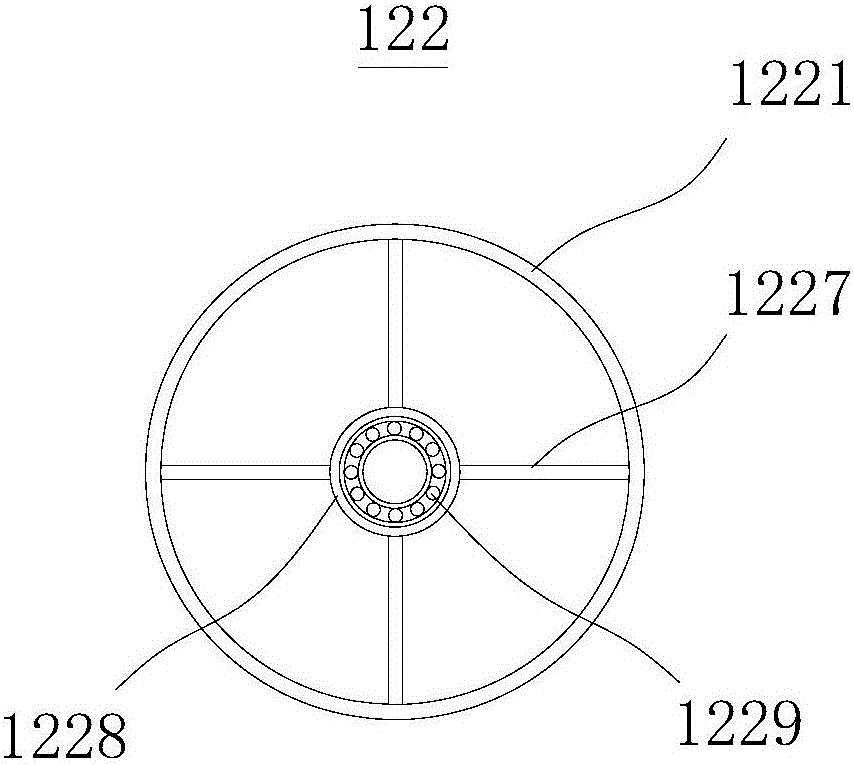

[0035] Such as figure 1 , the present embodiment provides a kind of bean harvester 100, which mainly includes digging device 130, conveying device 140, feeding chute 180, threshing device 120, receiving hopper 170, the above-mentioned components and other necessary parts The components are connected with the frame 110 to form the whole oily bean harvester 100. Digging device 130 is arranged at the front end of frame 110, and conveyer 140 is arranged adjacent to digging device 130, and threshing device 120 is arranged at the afterbody of frame 110, and its feeding end 1224 faces forward, and discharge end 1226 Towards the rear; the receiving hopper 170 is arranged below the threshing device 120 ; the feeding chute 180 is arranged between the end of the conveying device 140 and the feeding end 1224 of the threshing device 120 .

[0036]Digging and picking up grain device 130 excavates the oily bean plants in the field, and picks out the plants from the soil through the grain pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com