Cotton picker

A cotton picking machine and cotton picking technology, which is applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of poor cotton fiber quality and easy clogging, and achieve reasonable structure, high suction power and high separation rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

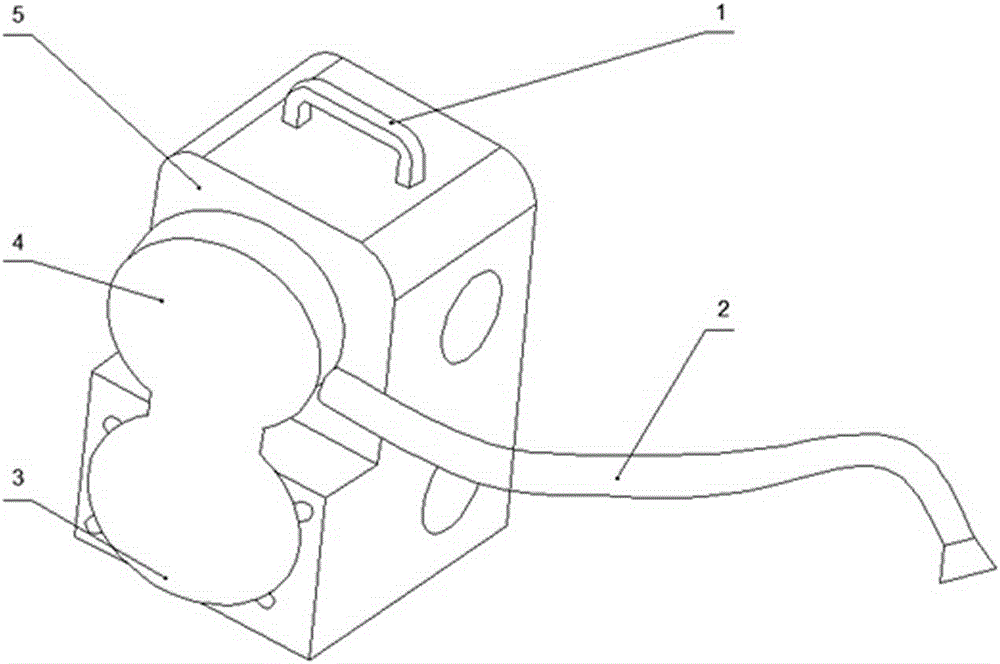

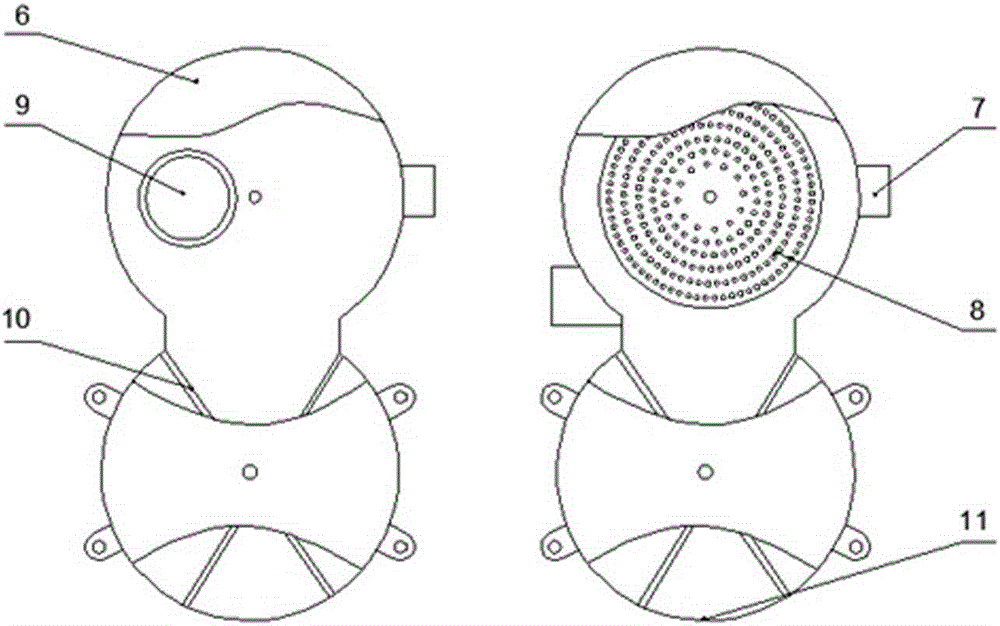

[0018] exist figure 1 Among them, the cotton picker can be divided into five parts: cotton picking handle, hose, cotton air separation box, centrifugal fan and chassis; the function of the cotton air separation box is to separate the cotton from the air flow, and to ensure the airtightness of the device during the separation process. 6 is the separation box shell, and 7 is the separation box inlet, which is connected to the cotton picking hose. After the cotton and the air flow are sucked together, the air flow will enter the centrifugal fan from the separation box air flow outlet 9, and the cotton will be picked on the net cover 8, and the cotton will be picked. When the cotton machine is working, the net cover is rotating, and the cotton can be thrown down by centrifugal force, and the cotton falls to the lower part of the separation box. The closed wind wheel 10 also has a sealing function. The edge of the vane is closely matched with the periphery and two ends of the separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com