Beef curing equipment

A kind of equipment and beef technology, applied in the direction of food science, etc., can solve the problems of puncture degree, long time, shrinkage, affecting the appearance and taste of meat, etc., and achieve the effect of ensuring the marinating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

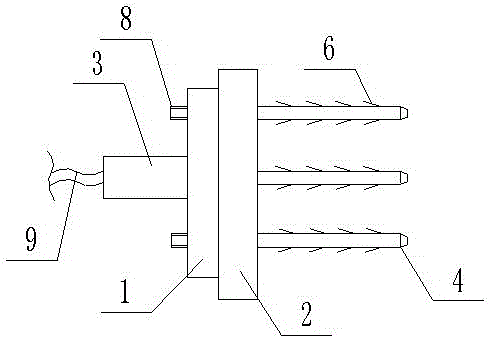

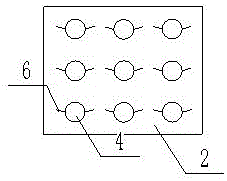

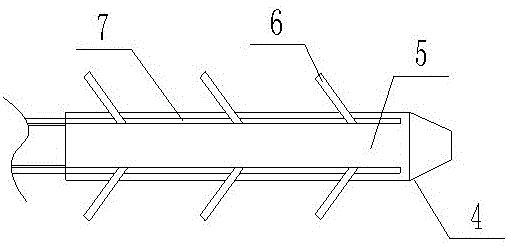

[0019] The reference signs in the accompanying drawings of the description include: base 1 , needle holder 2 , handle 3 , puncture needle 4 , cavity 5 , protruding thorn 6 , linkage lever 7 , operating handle 8 , and delivery pipe 9 .

[0020] basically as figure 1 Shown:

[0021] The marinating equipment for beef in this embodiment includes a base 1, a needle base 2 and a handle 3; There are several puncture needles 4 arranged on it, and the material of the puncture needles is stainless steel, which is not easy to rust and is easy to clean; two rows of convex thorns 6 are arranged on the outer wall of the puncture needles 4, and pickling liquid is perfused from both sides of the puncture needles, so that the pickling area is larger. more, the perfusion of the pickling solution is faster and more sufficient; the base 1 is provided with an operating handle 8 connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com