Device for removing dust blocking in filter of dust collector

A technology of filters and vacuum cleaners, which is applied in the direction of cleaning filter devices, etc., and can solve problems such as low efficiency, inconvenient cleaning, troublesome and troublesome

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

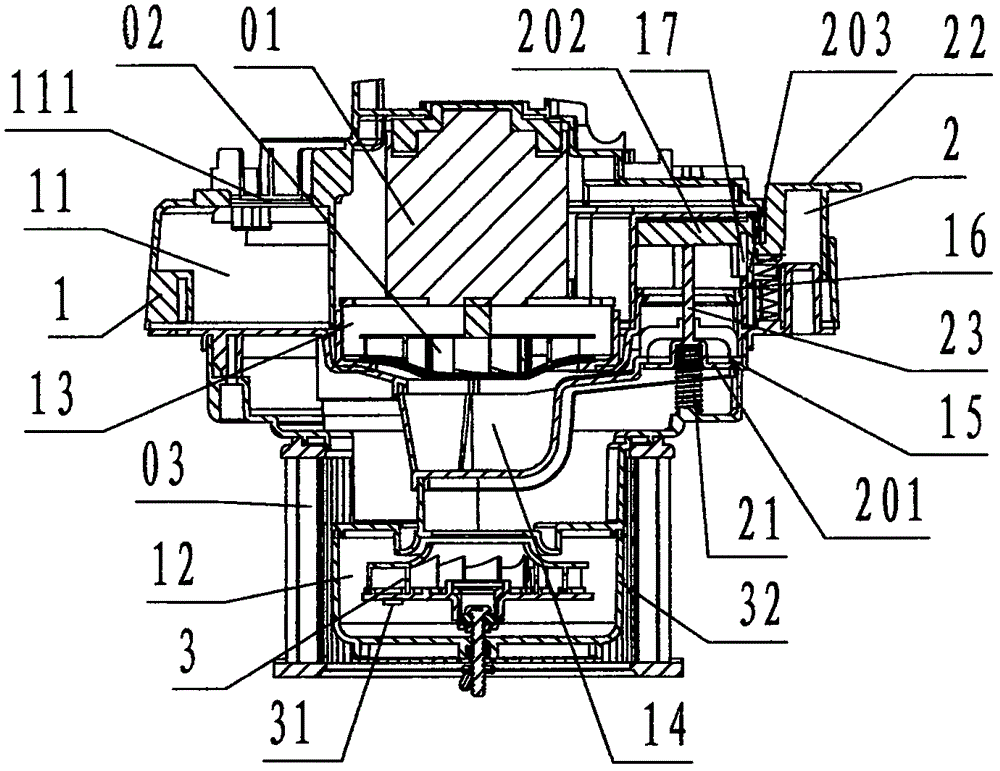

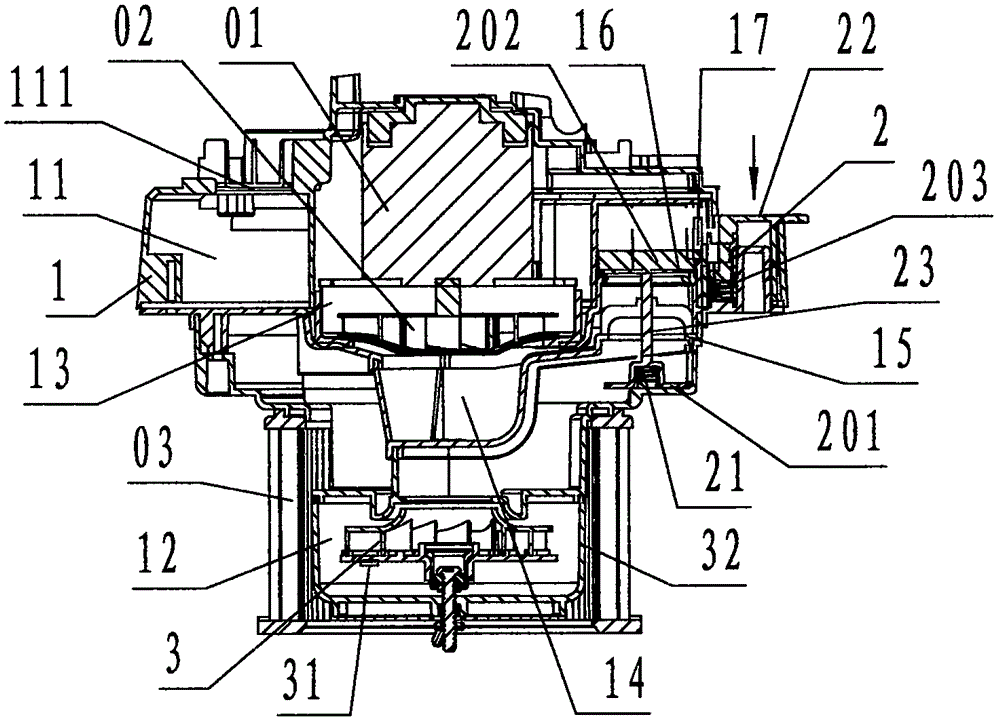

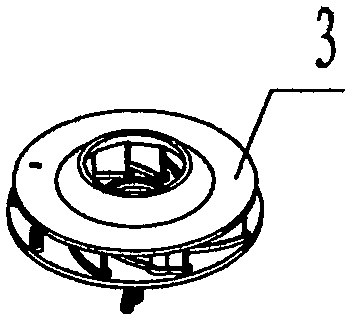

[0032] refer to Figure 1 to Figure 11 , a device for removing dust clogging of a vacuum cleaner filter according to the present invention, including a casing 1, a linkage valve core 2, and a wind-operated vibrating wheel 3, wherein: the casing 1 is hollow, the upper part is closed, the lower part is open, and the upper part is larger and the lower part is open. Small cylindrical steps describe cavity-shaped plastic components, the motor 01 is fixed at the center of the upper part of the inner cavity of the casing 1, the fan 02 is connected below the motor 01, and the filter 03 is fixed at the lower center of the casing 1; the surrounding motor 01 and Fan 02, the inside of the casing 1 is provided with an exhaust duct 11, a clearing air duct 12, a positive pressure chamber 13, a negative pressure chamber 14, a normally closed valve port 15, a normally open valve Port 16 and the normally closed side valve port 17; wherein, the chamber corresponding to the output end of the fan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com