Paint pneumatic vibration filtering device

A technology of pneumatic vibration and filtration device, applied in the direction of moving filter element filter, filtration separation, separation method, etc., can solve the problems of filter blockage, high manufacturing cost, poor paint filtration effect, etc., to facilitate replacement and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

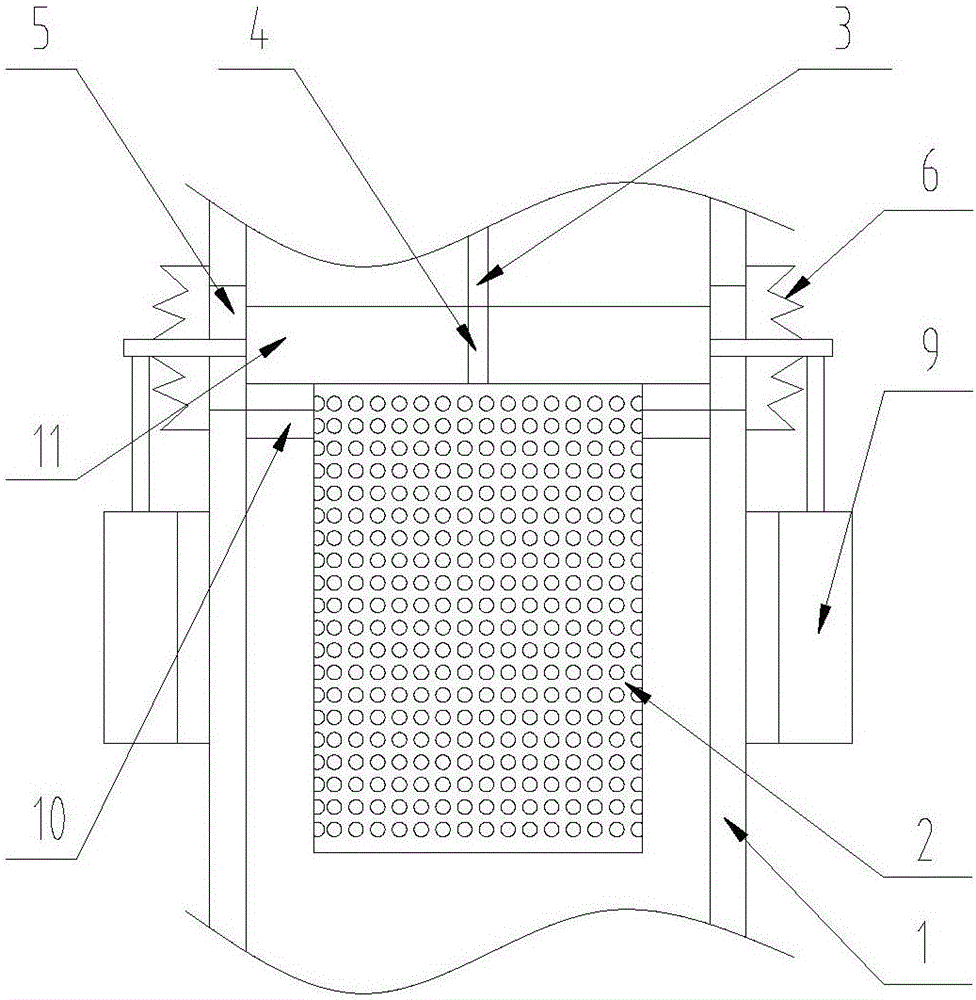

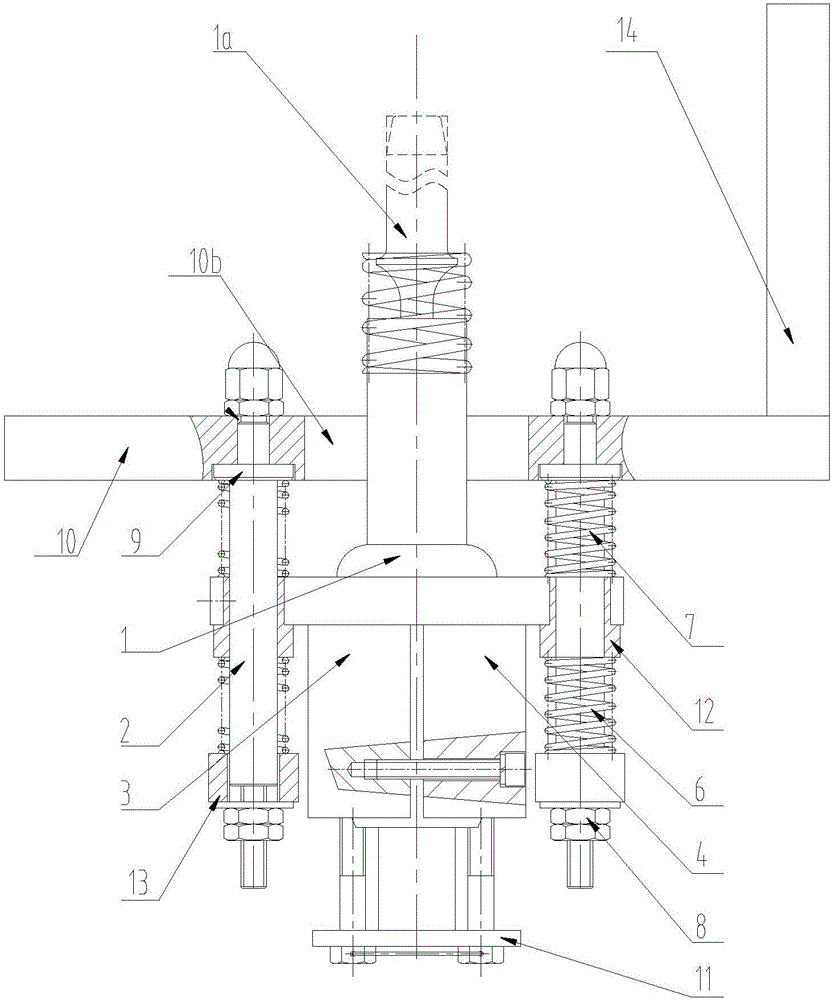

[0028] A paint pneumatic vibration filter device, including a connecting pipe, the upper and lower ends of the connecting pipe are respectively provided with threaded connection ports (not shown) for connecting with the oil pipeline, a filter bucket is erected in the connecting pipe, and the filtering The length of the barrel is 1.5 times the diameter. The pipe wall of the connecting pipe is provided with guide grooves in the axial direction, guide protrusions are provided on the outer peripheral surface of the filter barrel to slide and cooperate with the guide grooves, and the outer peripheral surface of the filter barrel is provided with threads in the radial direction Connecting hole, the pipe wall of the connecting pipe is provided with a relief bar hole in the axial direction corresponding to the threaded connection hole, and the pipe wall of the connecting pipe is covered with a bellows to completely cover the relief strip on the pipe wall of the connecting pipe shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com