Patents

Literature

55results about How to "Facilitates axial positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

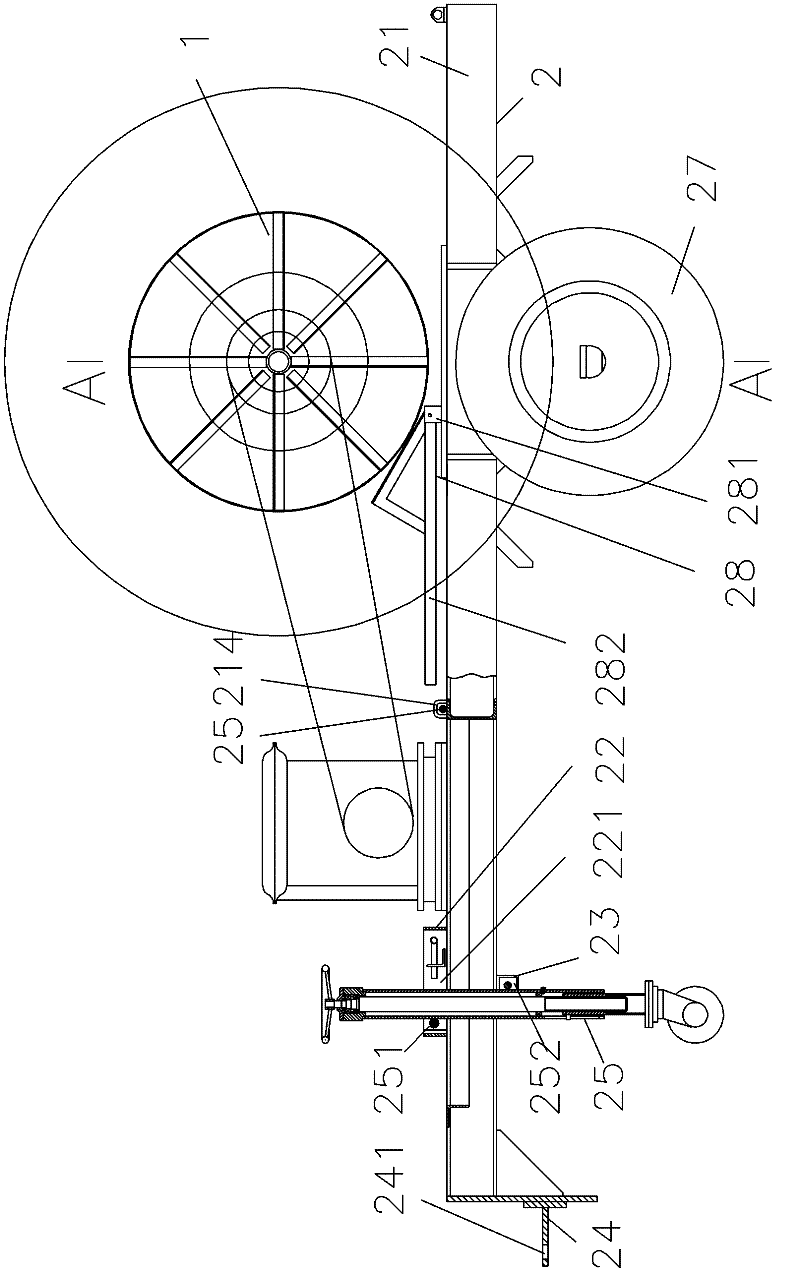

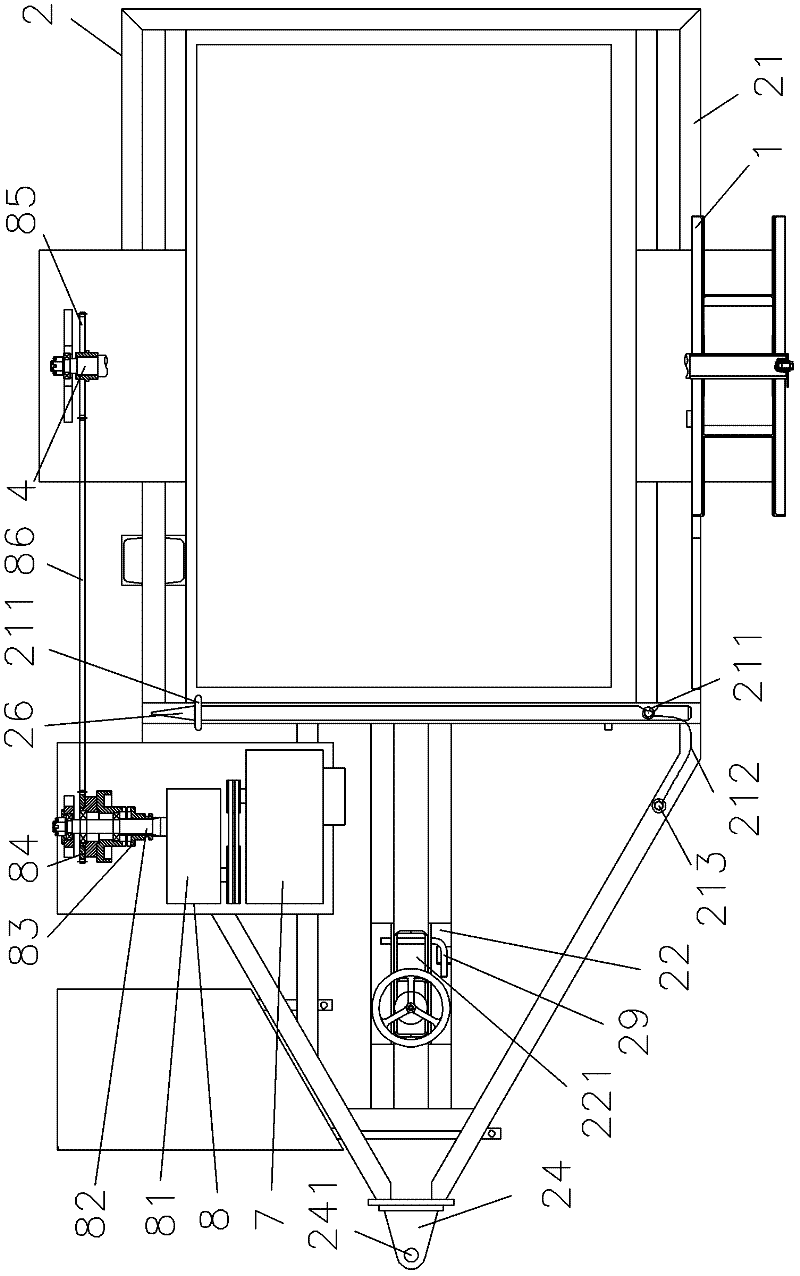

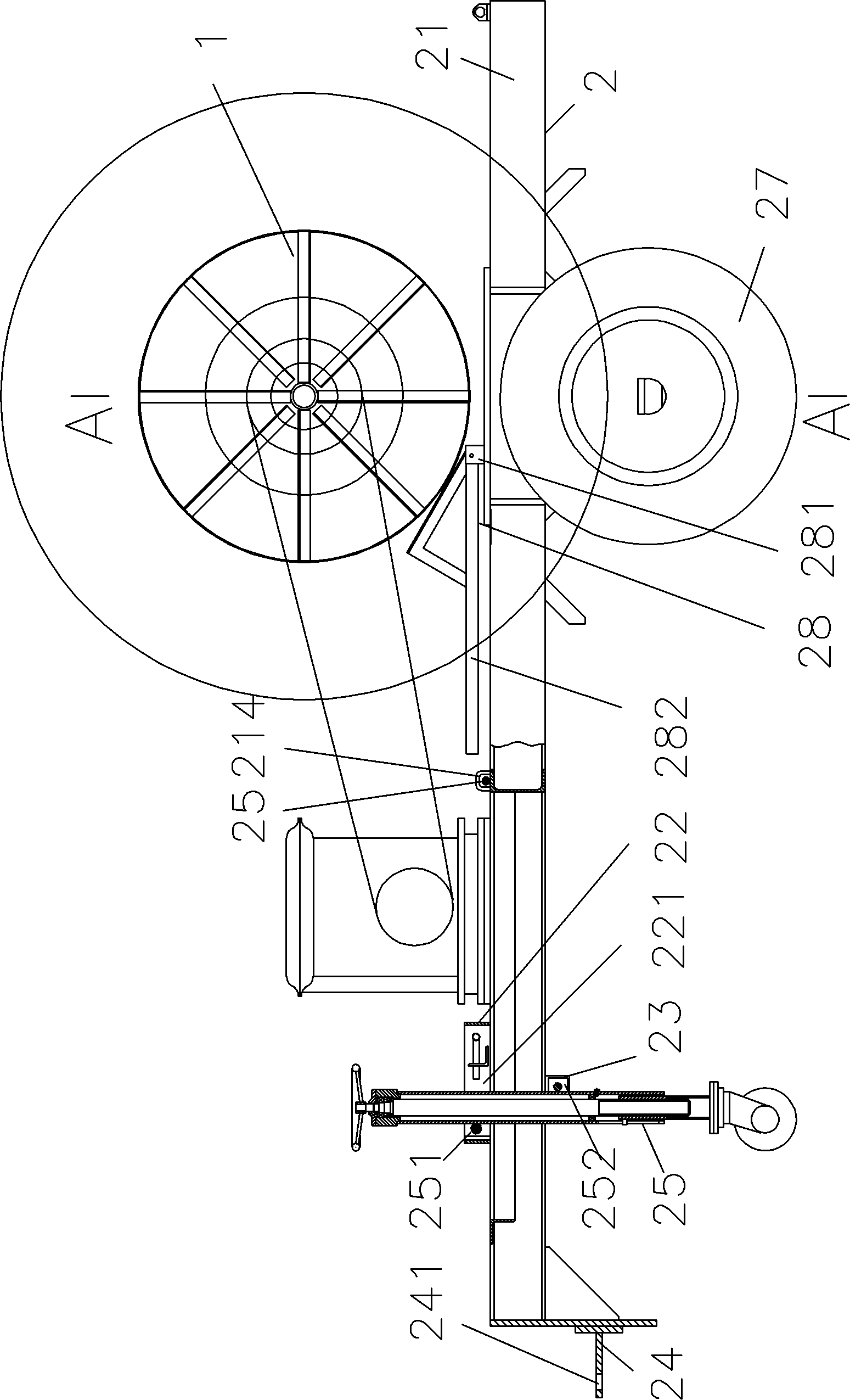

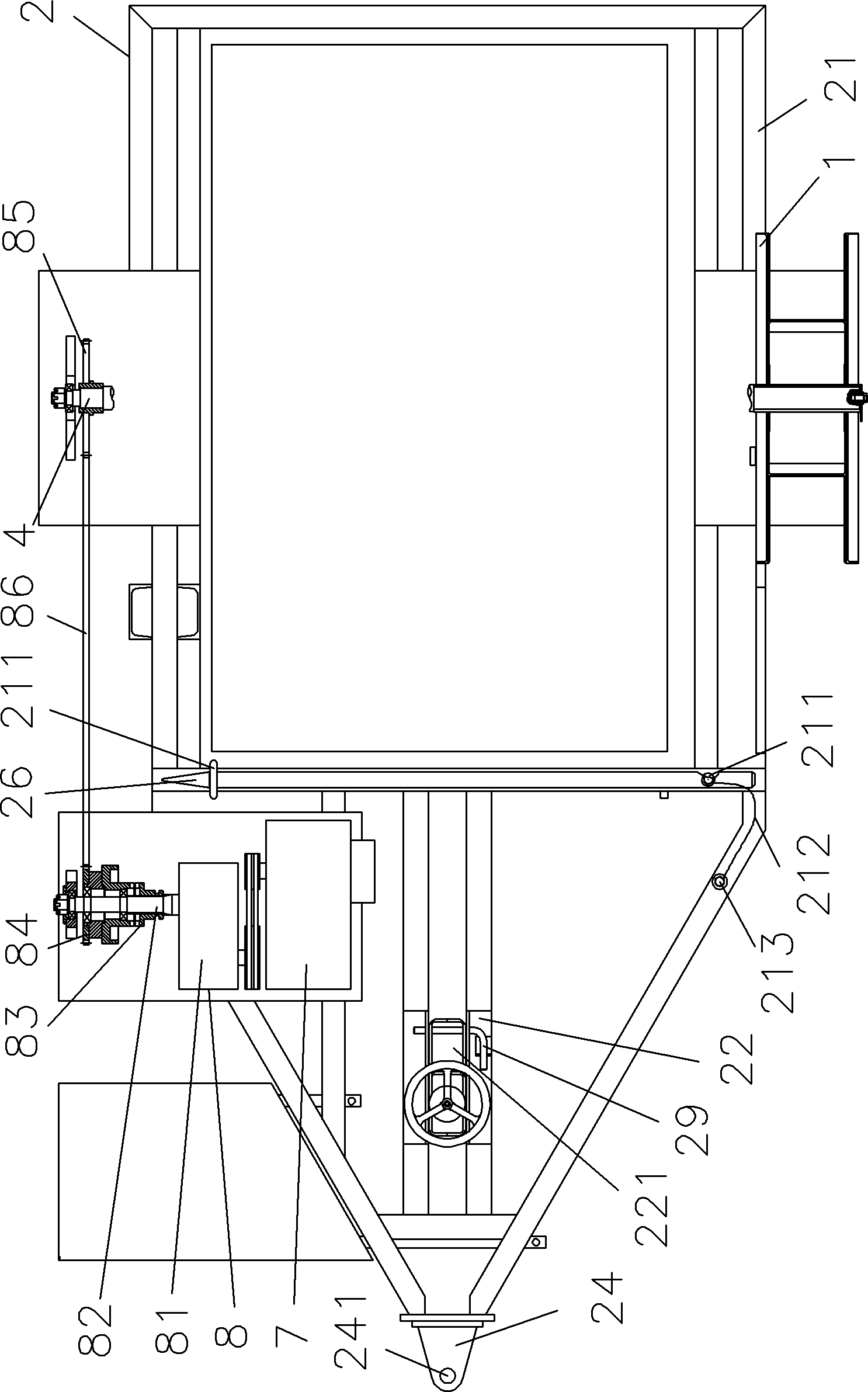

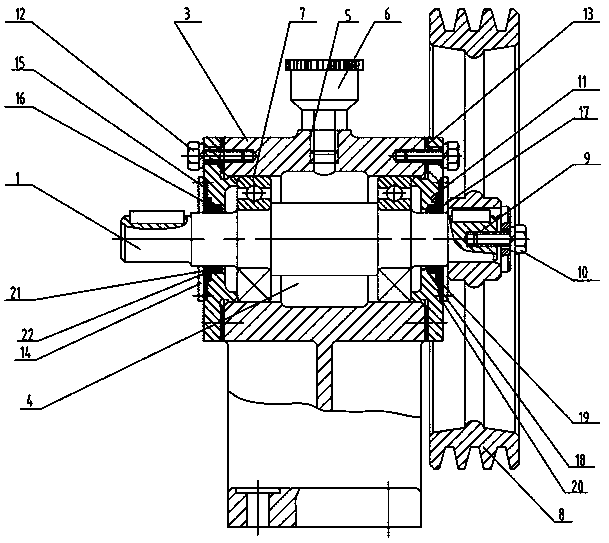

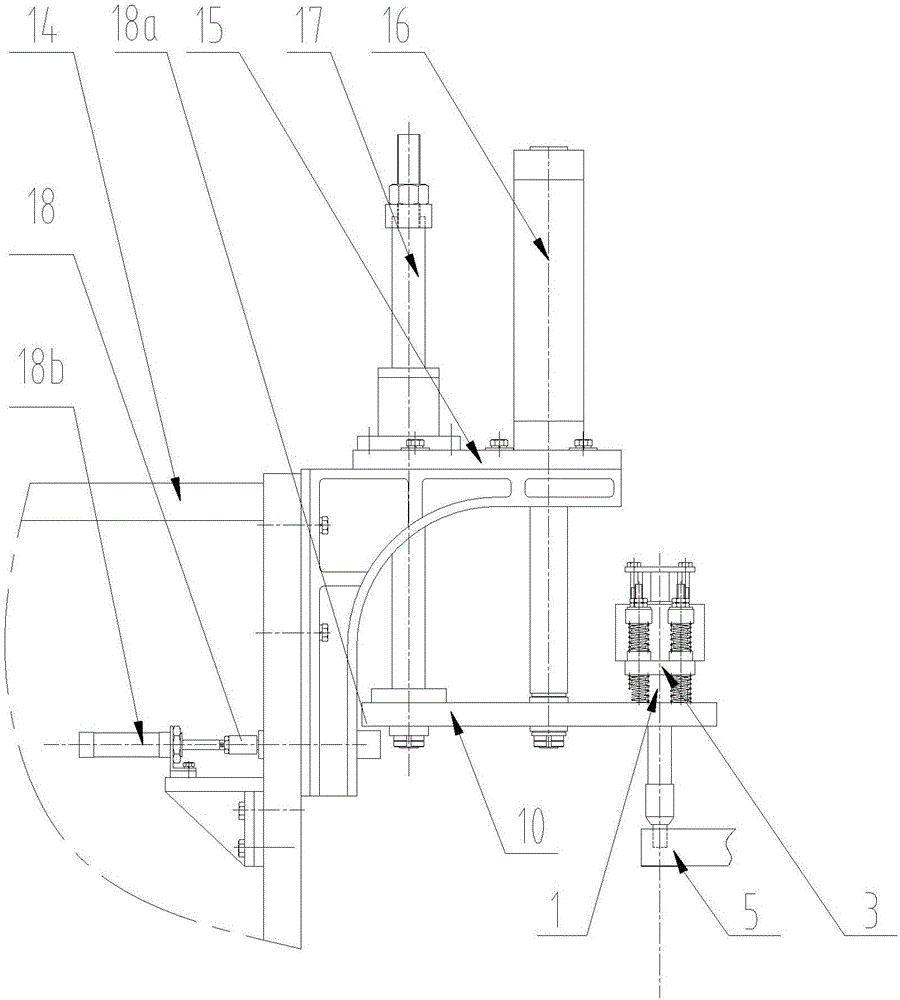

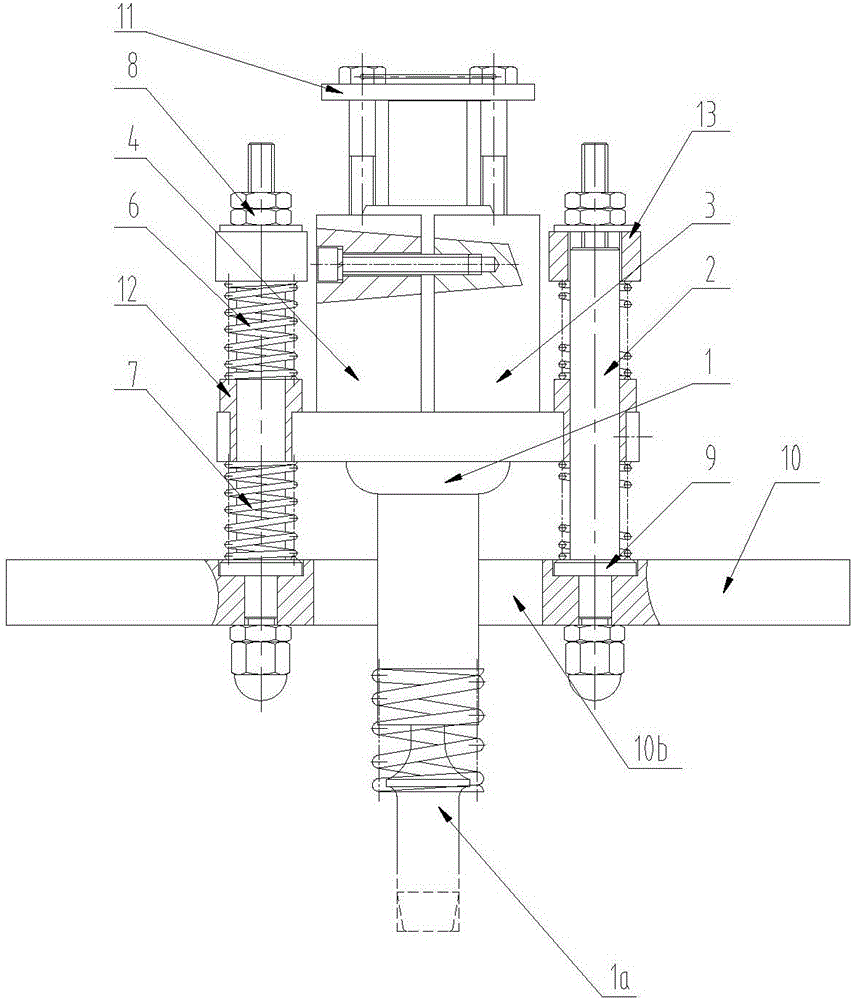

Cable wire barrow

ActiveCN102655316AConvenient parkingFirmly connectedArrangements using take-up reel/drumVehicle frameEngineering

The invention relates to the field of cable taking-up and paying-off equipment, and aims to provide a cable wire barrow of which a transmission mechanism between a power machine and a take-up drum has functions of overload protection and labor conservation by manually rotating the take-up drum. The cable wire barrow comprises a car frame with wheels, a bearing frame, a rotating shaft, a driving device which is used for driving the rotating shaft, a transmission device, a wire plate shaft, a traction rope plate, a transmission fork and an opening and closing retainer, wherein the wire plate shaft comprises a connecting section, a cable section, a bearing section and a traction section which are connected with one another in sequence; the rotating shaft comprises a transmission section and a supporting section; the transmission section of the rotating shaft is pivoted with the bearing frame, and the transmission fork is sleeved outside the supporting section and is fixedly connected with the supporting section; and the connecting section is detachably and fixedly connected with the supporting section, the opening and closing retainer bears the bearing section, and the traction rope plate is sleeved outside the traction section. The cable wire barrow ensures that the paying off of cables is easy and labor-saving when the cables are relatively thick and heavy and a paying-off path is bumpy.

Owner:HANGZHOU ELECTRIC EQUIP MFG +3

Stroke control mechanism of metering pump

InactiveCN1796786ASimple processing technologyImprove stress conditionPump controlPumpsEngineeringMetering pump

A stroke regulating mechanism of metering pump consists of worm wheel, worm gear, regulating stem and eccentric wheel. It is featured as connecting eccentric wheel with link lever and setting bush between them, firm ¿C joining L form shaft with regulating stem below the regulating stem to use L form shaft to regulate stroke of metering pump.

Owner:ZHEJIANG UNIV OF TECH

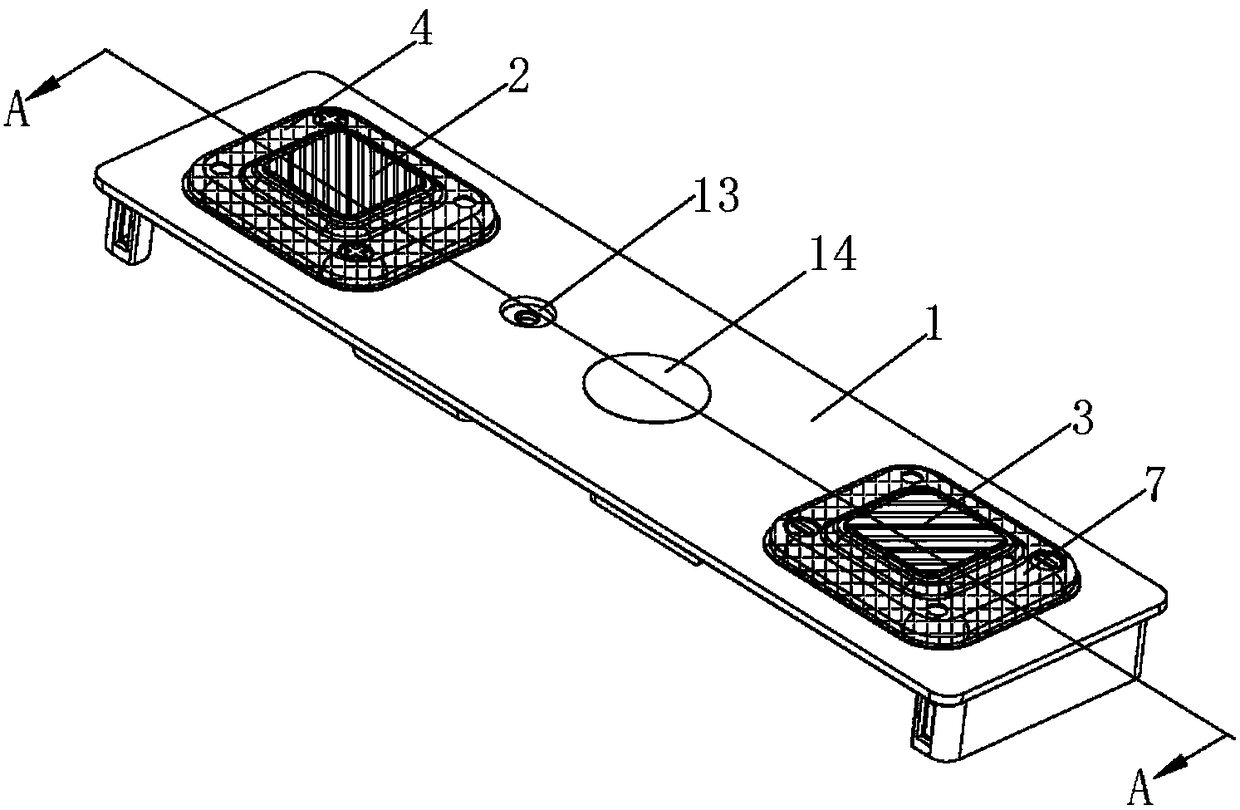

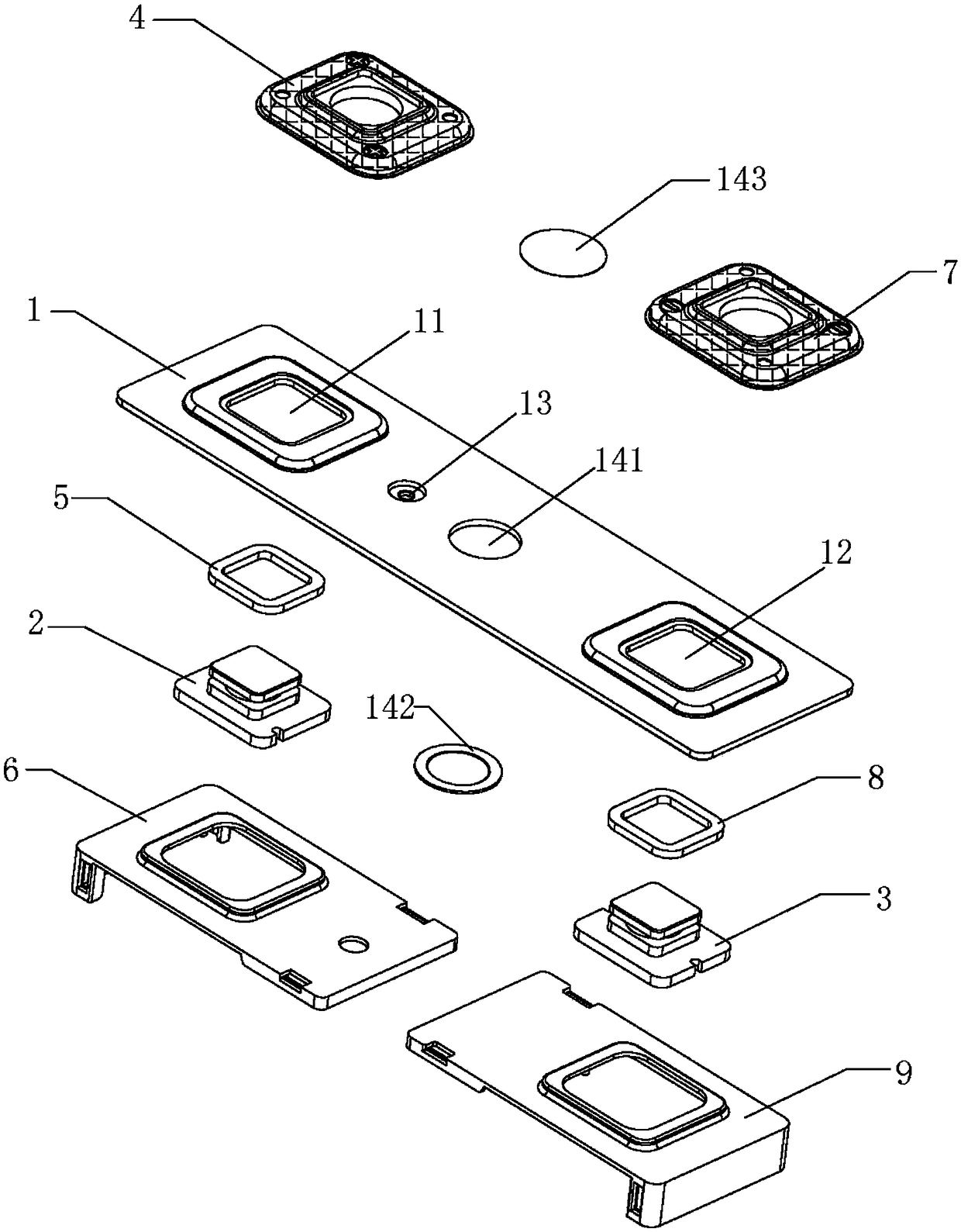

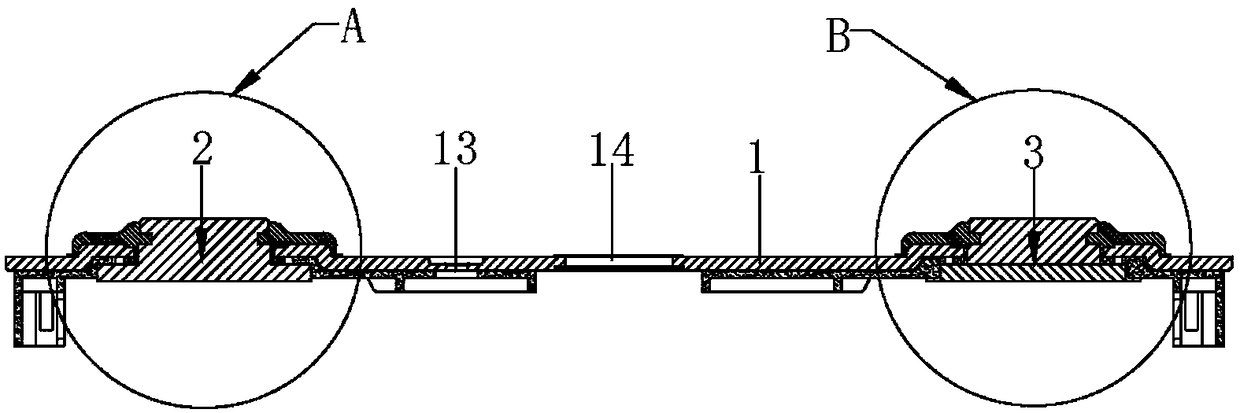

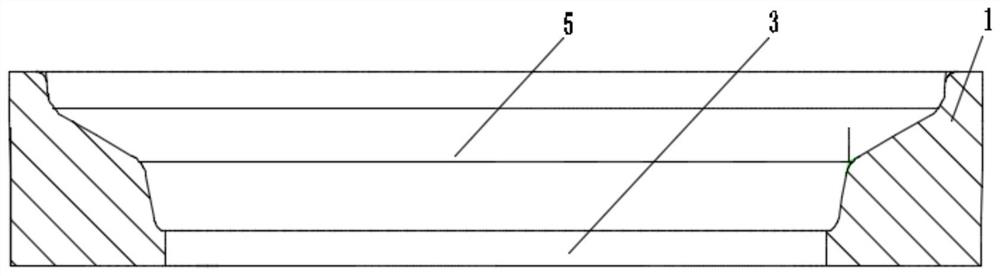

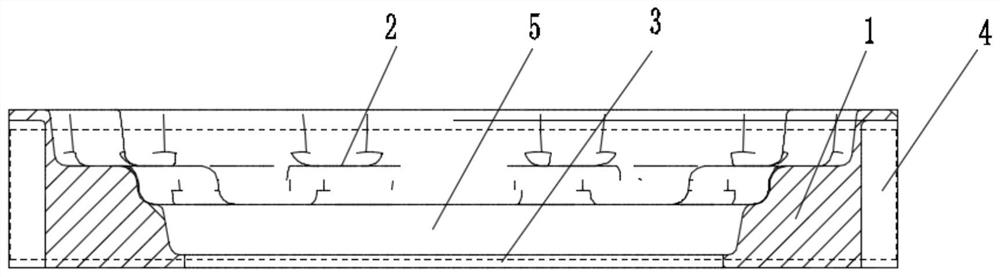

Top cover of power battery, assembly method thereof and power battery

PendingCN108365138AFacilitates axial positioningReduce usageAssembling battery machinesFinal product manufacturePower batteryElectrical and Electronics engineering

The invention discloses a top cover of a power battery. The top cover of the power battery comprises a top cover sheet, a first terminal post, a second terminal post, a first mounting hole, a second mounting hole, an explosion-proof valve and a liquid filling hole, wherein the first terminal post, the second terminal post, the first mounting hole, the second mounting hole, the explosion-proof valve and the liquid filling hole are arranged on the top cover sheet; the first terminal post is mounted in the first mounting hole; the second terminal post is mounted in the second mounting hole; the first terminal post comprises a first matrix part and a second matrix part; a first column part is arranged between the first matrix part and the second matrix part; a first groove is formed among thefirst matrix part, the first column part and the second matrix part; a first seal ring sleeves the first column part; conductive plastic parts are arranged among the first matrix part, the first column part, the first seal ring and the top cover sheet; and a first insulating part is arranged among the second matrix part, the first seal ring and the top cover sheet. An H-shaped terminal post structure of the top cover of the power battery can achieve a good axial positioning effect on top cover parts, so the top cover of the power battery is compact and reliable in structure, dispenses with a riveting working procedure required by a T-shaped terminal post with a conductive block, reduces production cost and improves assembly efficiency.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

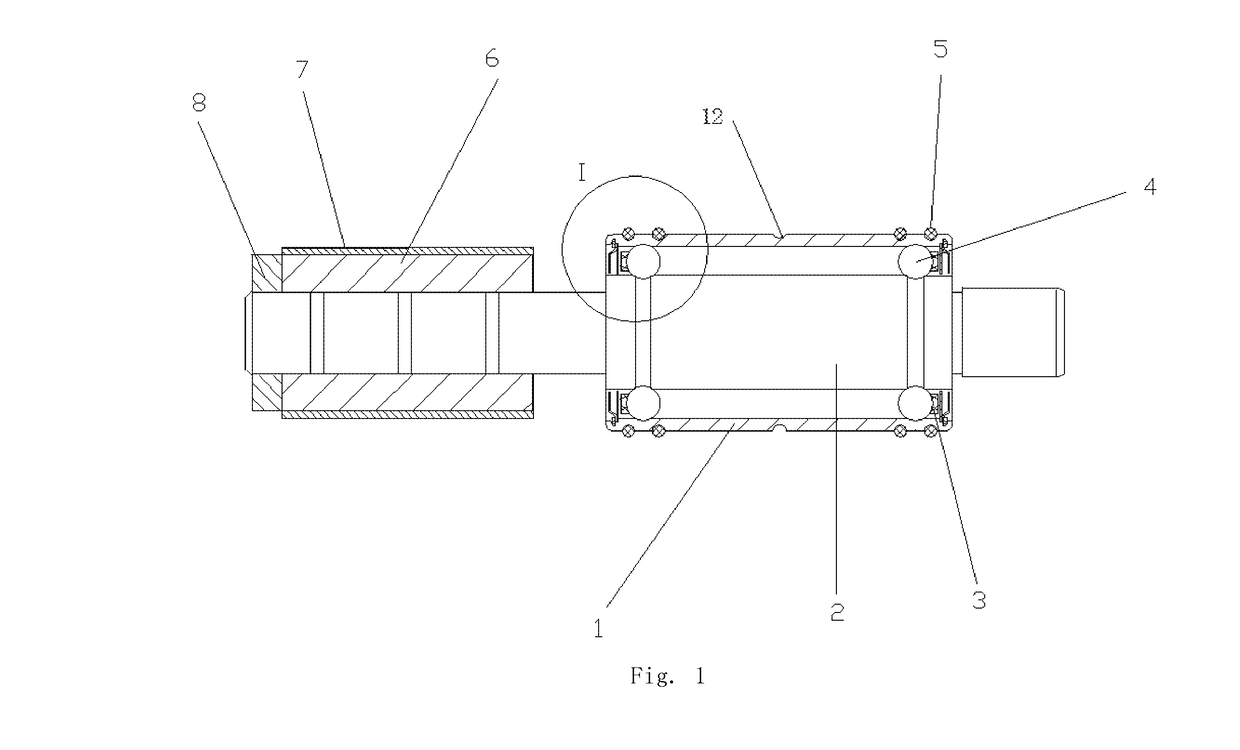

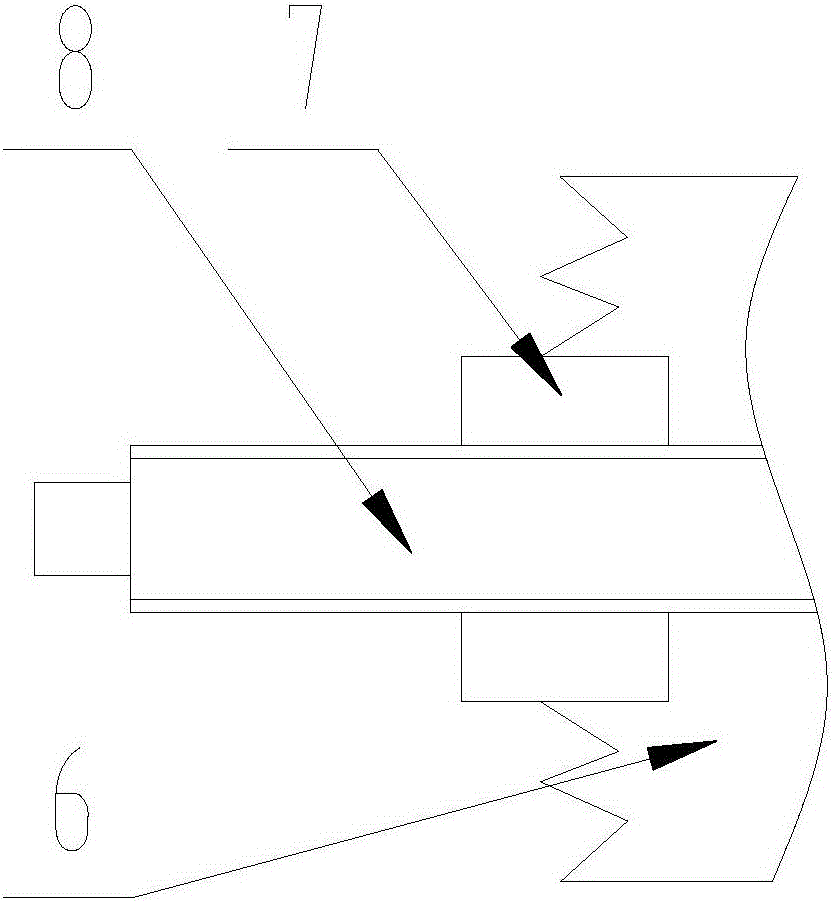

Horizontal guide device for crane

ActiveCN103434931AReduce replacementSimple structureTravelling gearEngineeringHorizontal and vertical

The invention relates to the technical field of cranes, in particular to a horizontal guide device for a crane. The horizontal guide device comprises a mounting rack fixedly mounted on an end beam, two rotating sleeves are rotatably mounted on the mounting rack, and a locking structure is mounted between each rotating sleeve and the mounting rack and used for fixing the rotating sleeve on the mounting rack. Each rotating sleeve is internally provided with an eccentric shaft in an inserted mode; each eccentric shaft comprises a mounting part mounted in the corresponding rotating sleeve and an extending part extending out of the rotating sleeve; the mounting parts and the extending parts are not coaxial, and the mounting parts are in drive connection with the rotating sleeves through keys; two ends of each rotating sleeve are provided with locking nuts which are in threaded connection with the eccentric shafts; two horizontal guide wheels are rotatably mounted on the extending parts and are located at the two sides of a rail respectively. The horizontal guide device for the crane provided by the invention can realize adjustment of the horizontal guide wheels in the horizontal and vertical directions, is convenient to adjust and can ensure the operation safety of the whole crane.

Owner:SHANQI HEAVY MACHINERY

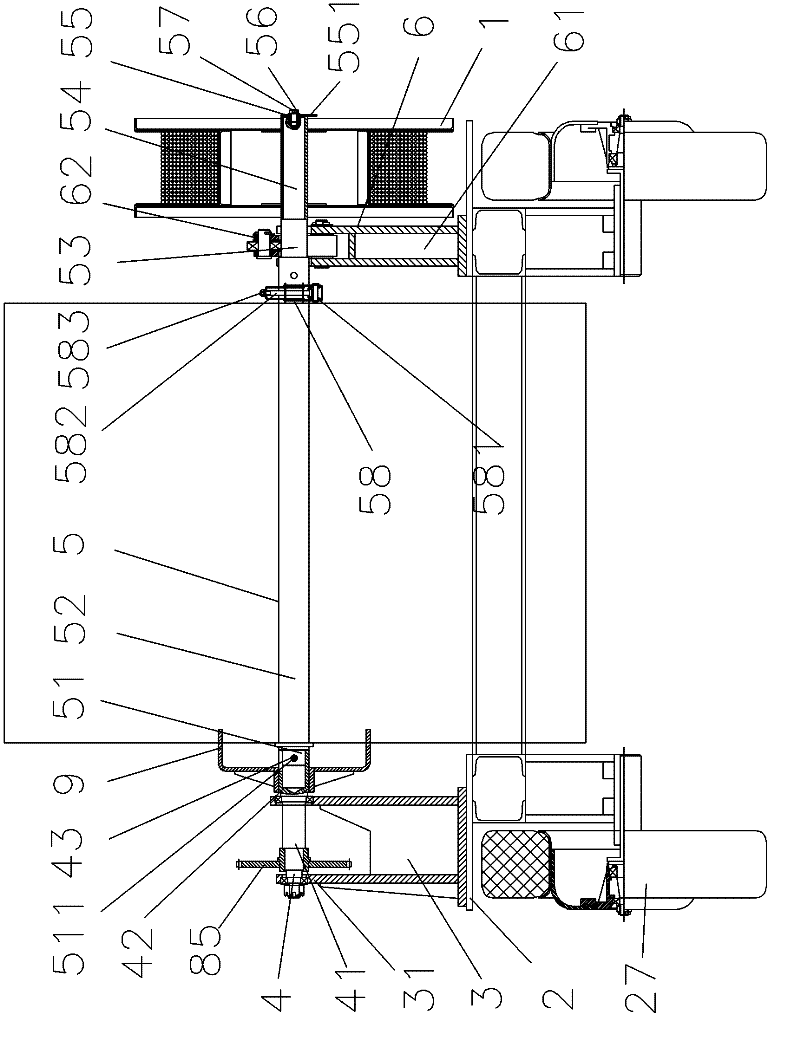

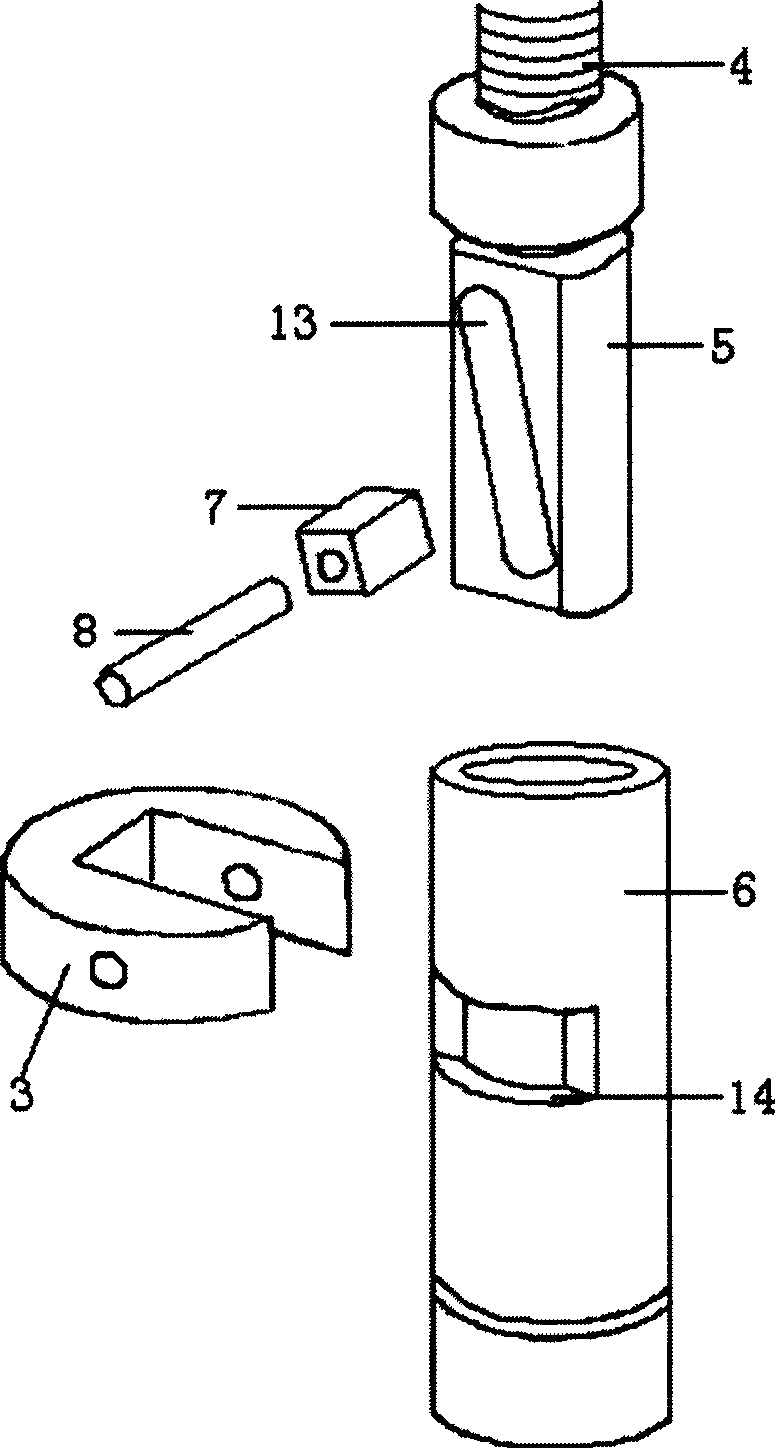

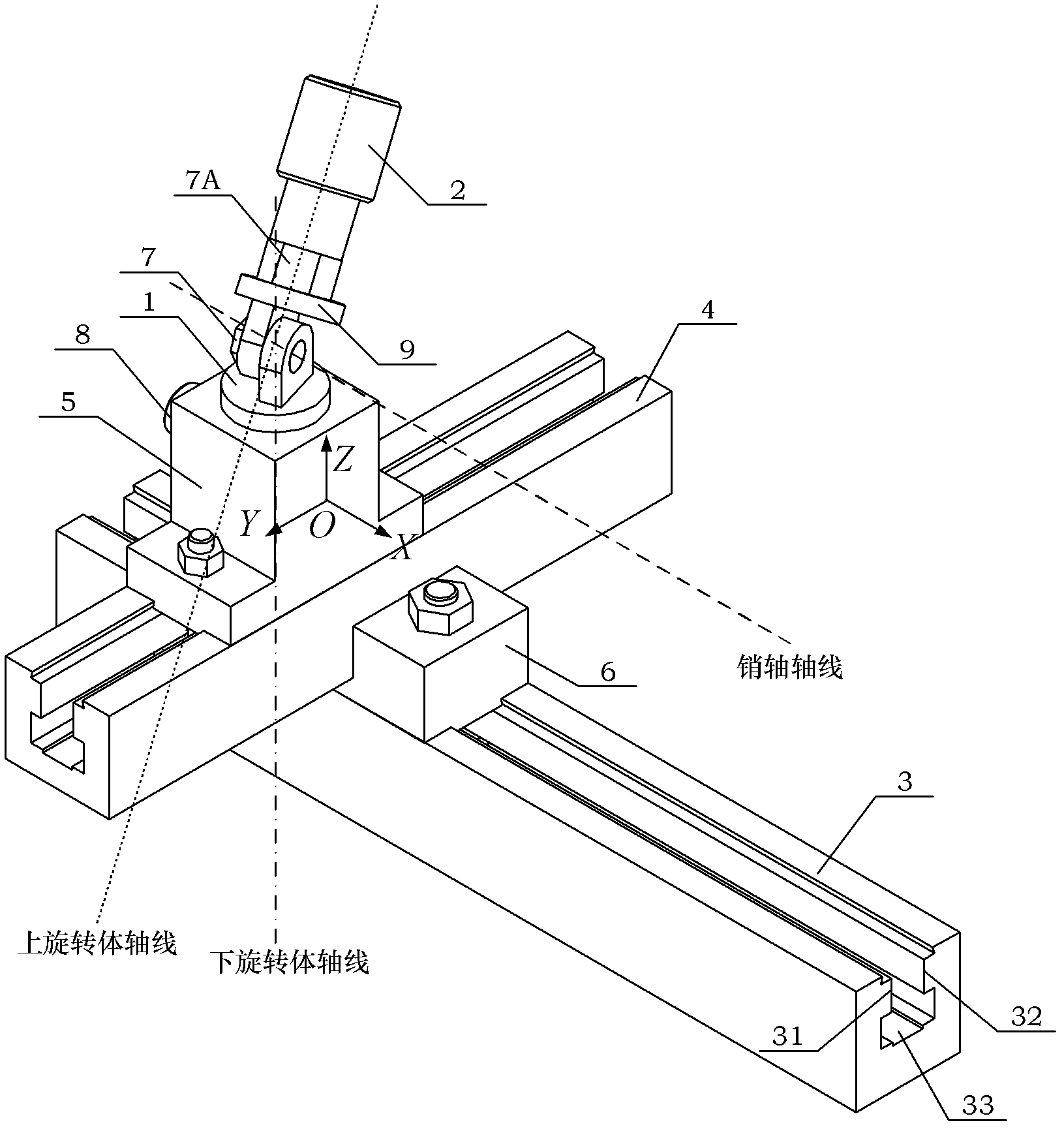

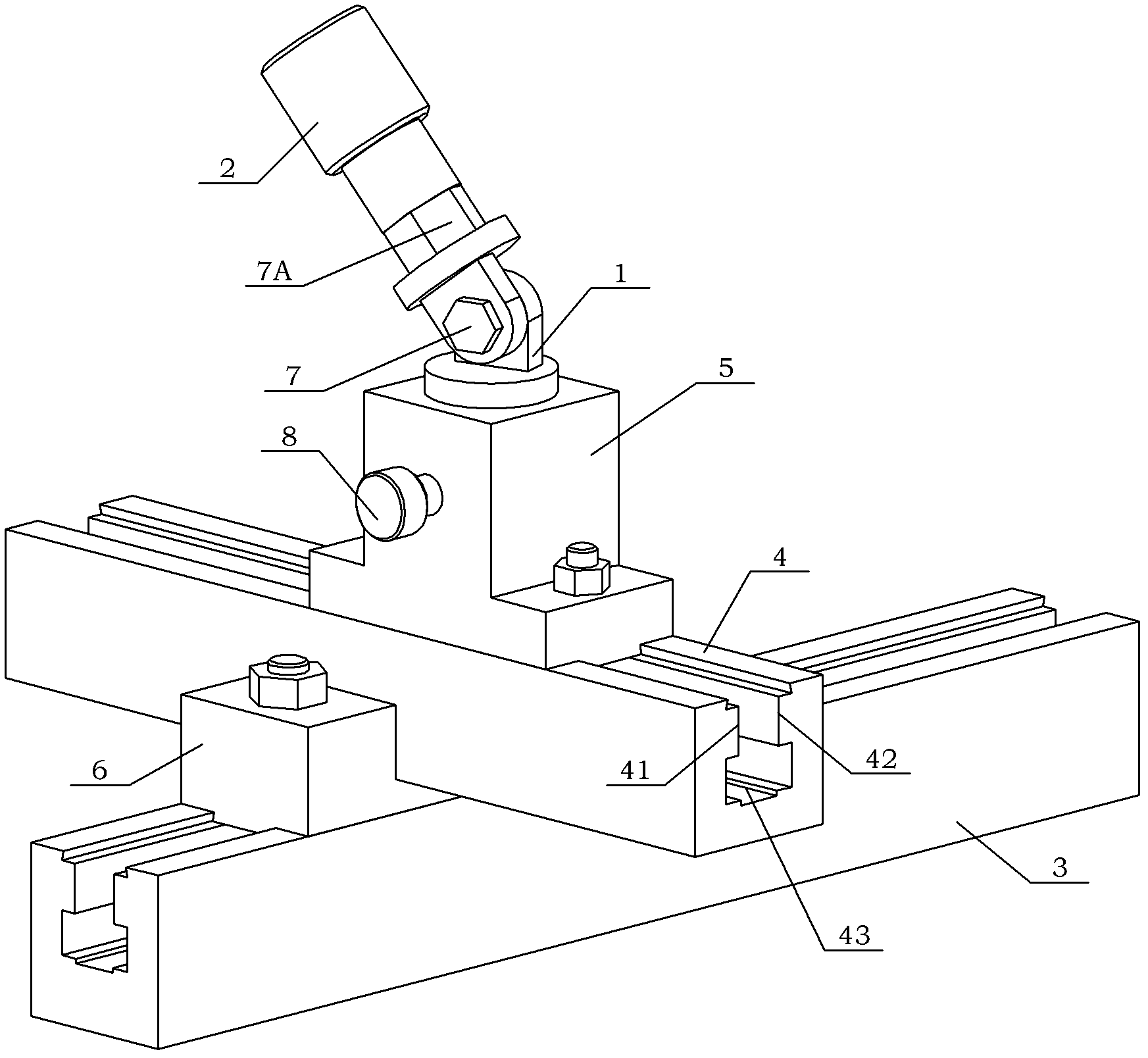

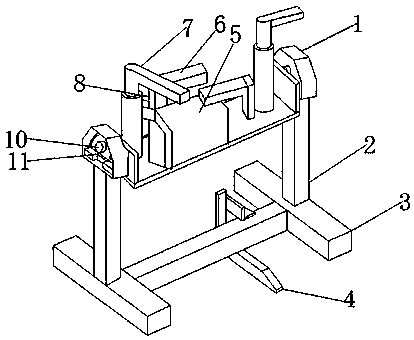

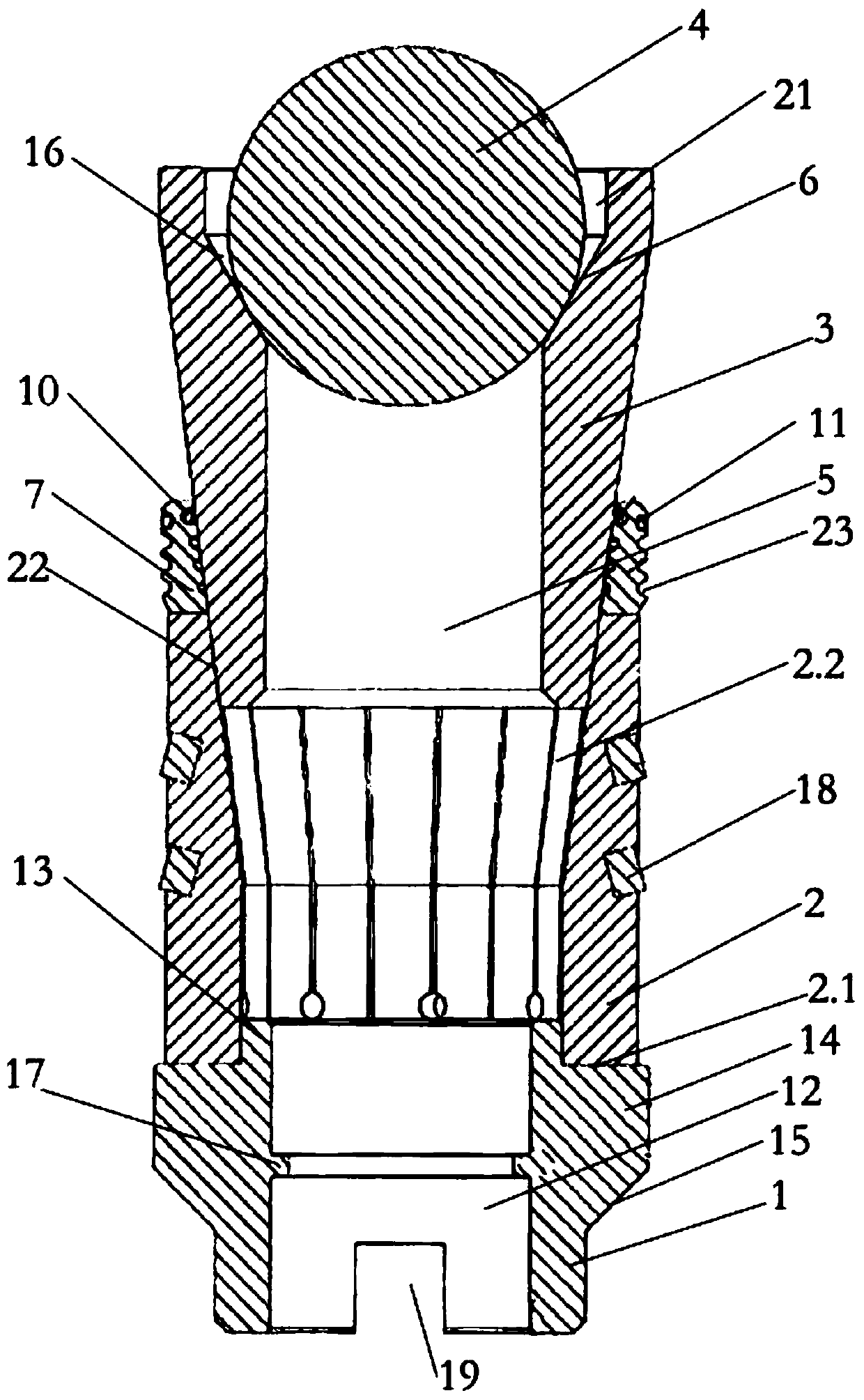

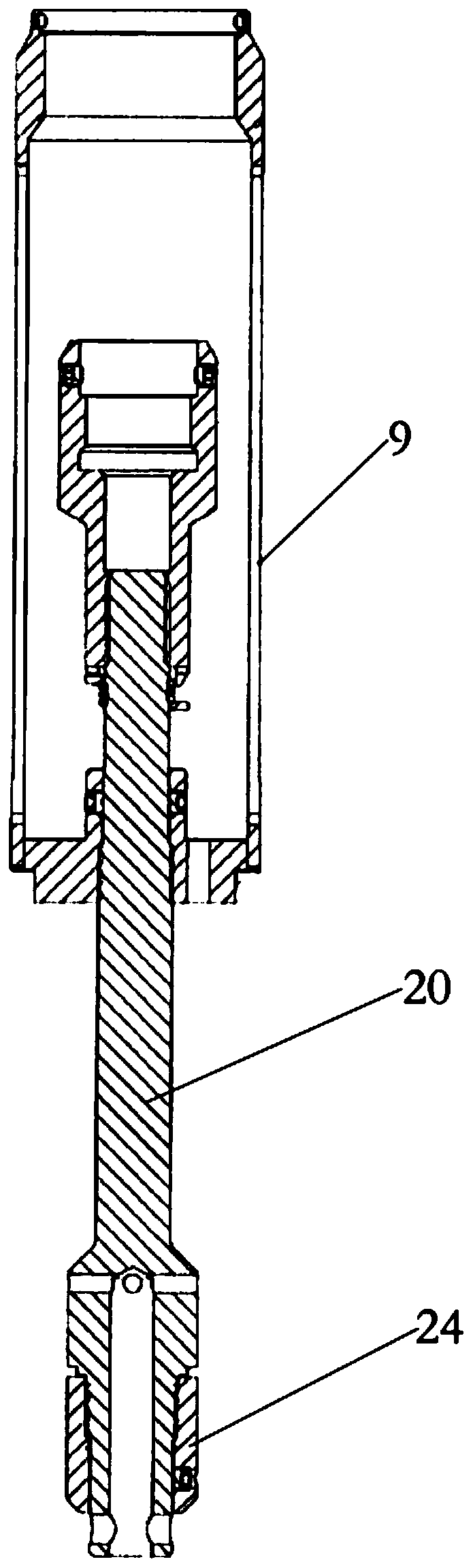

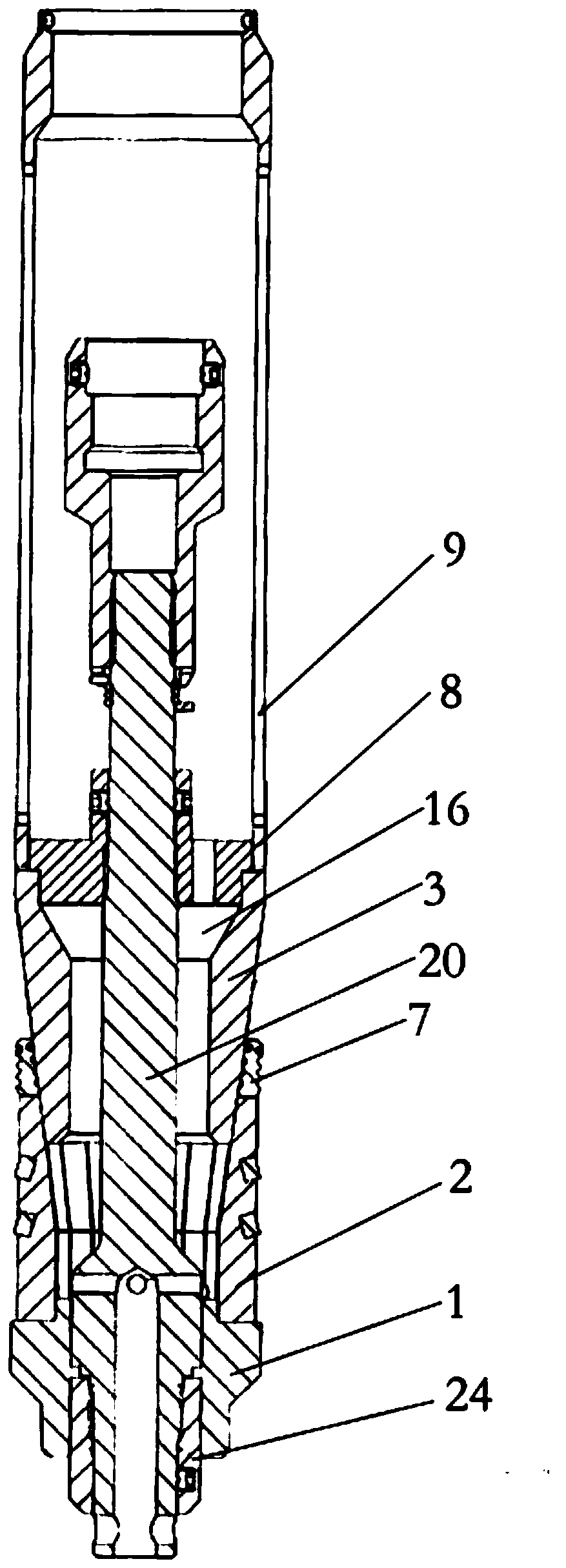

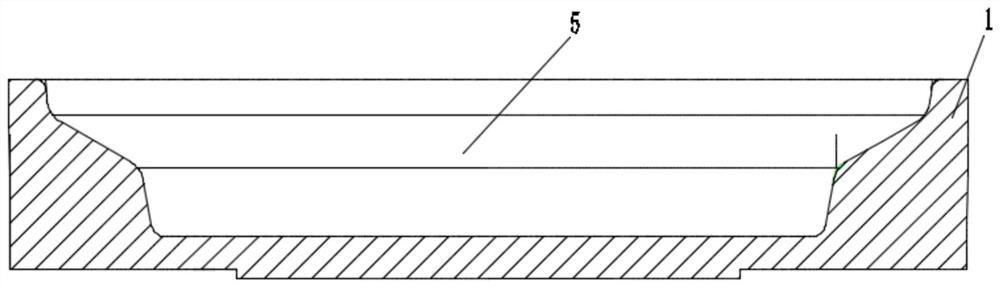

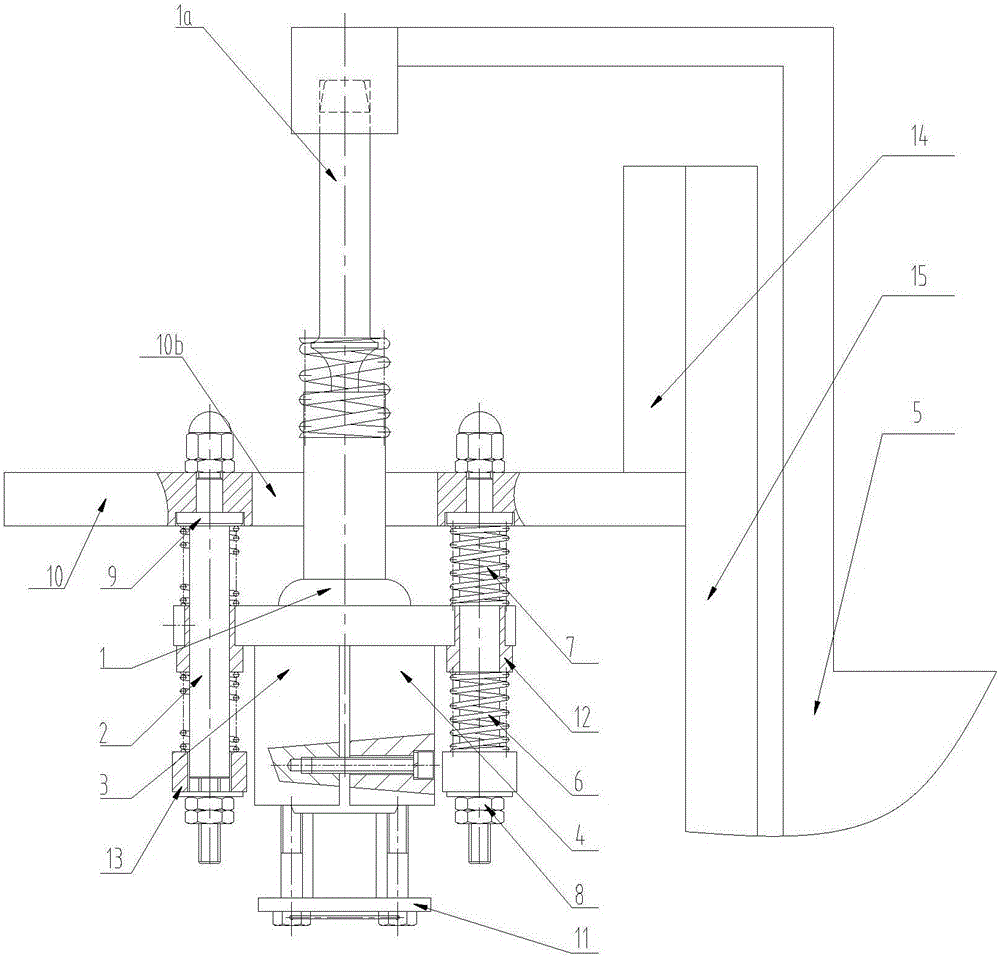

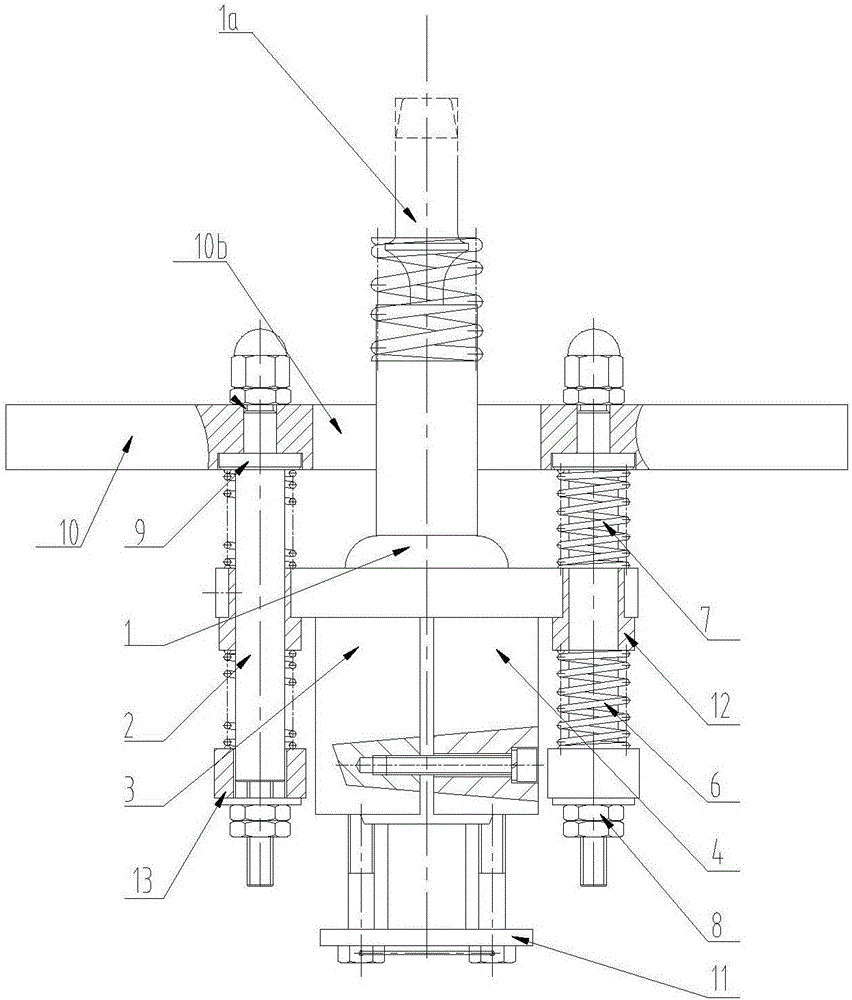

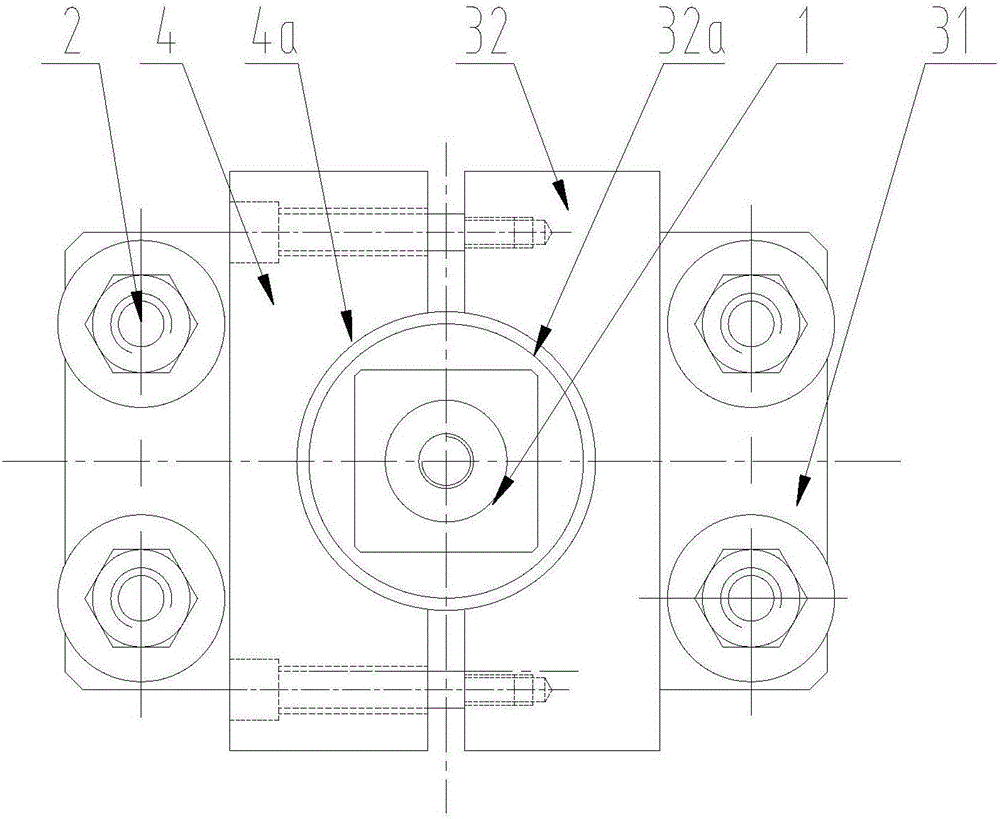

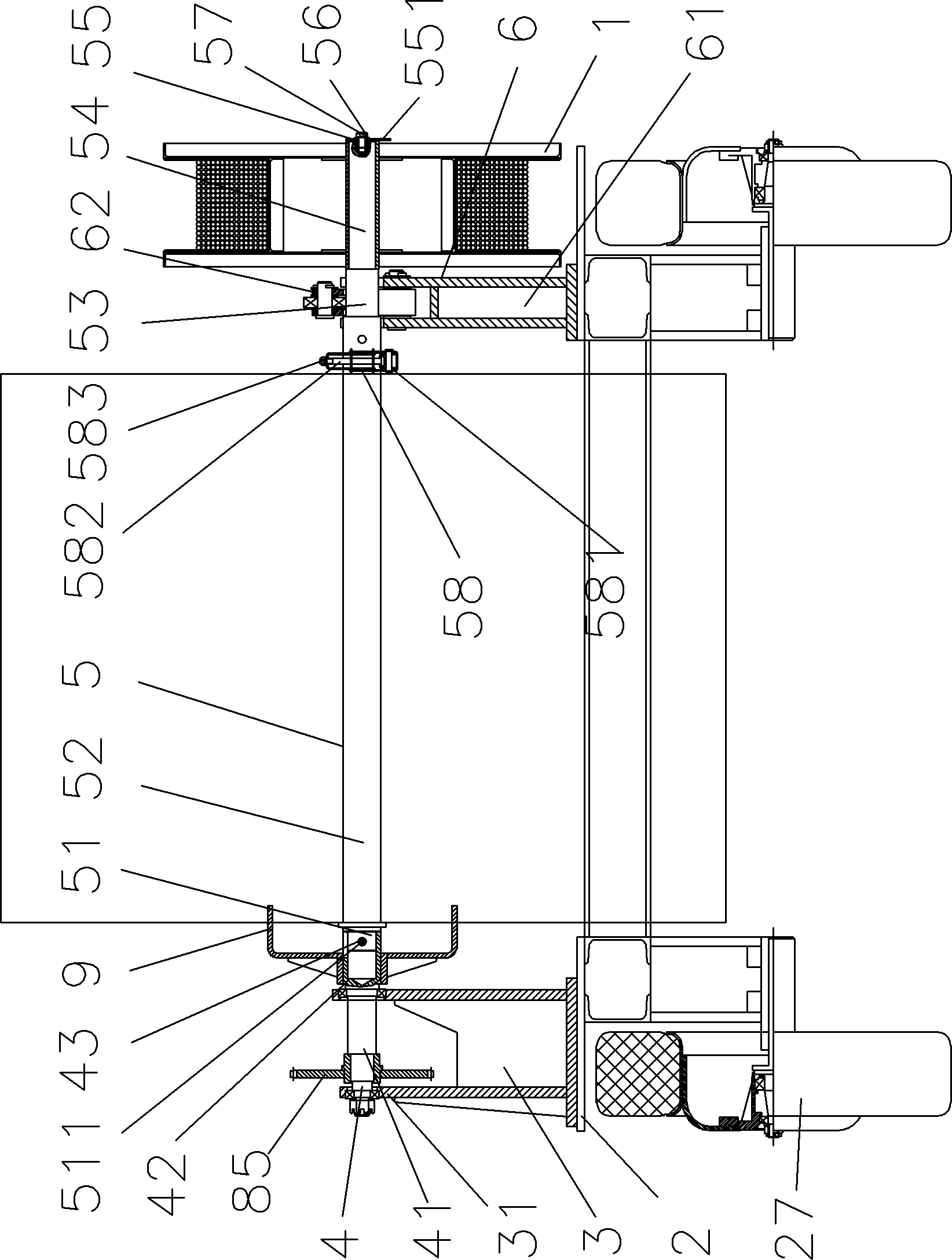

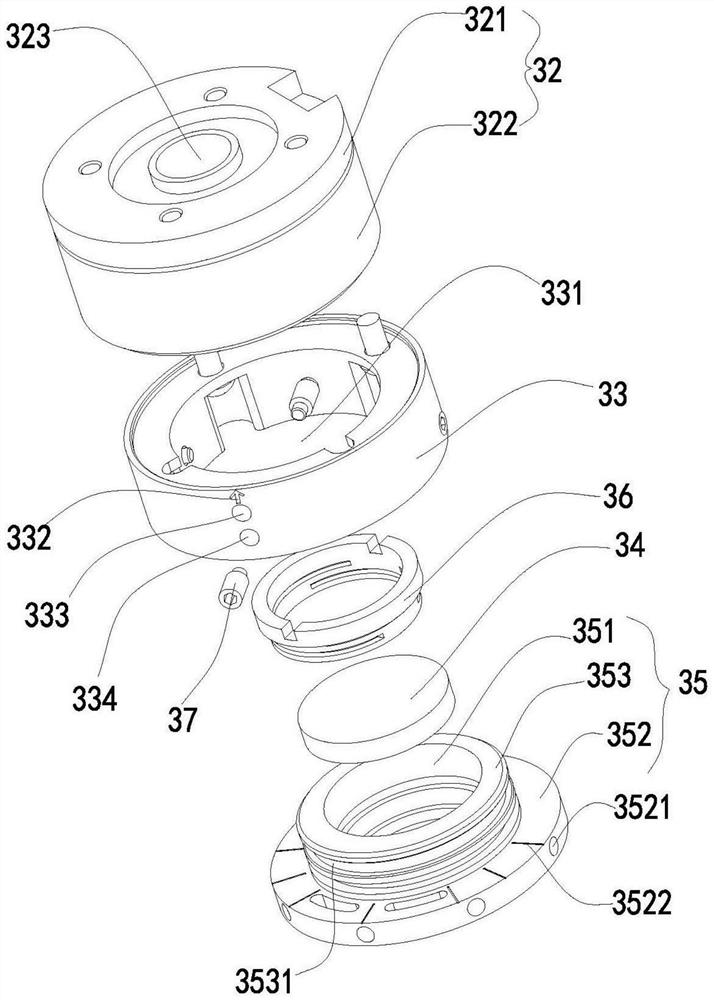

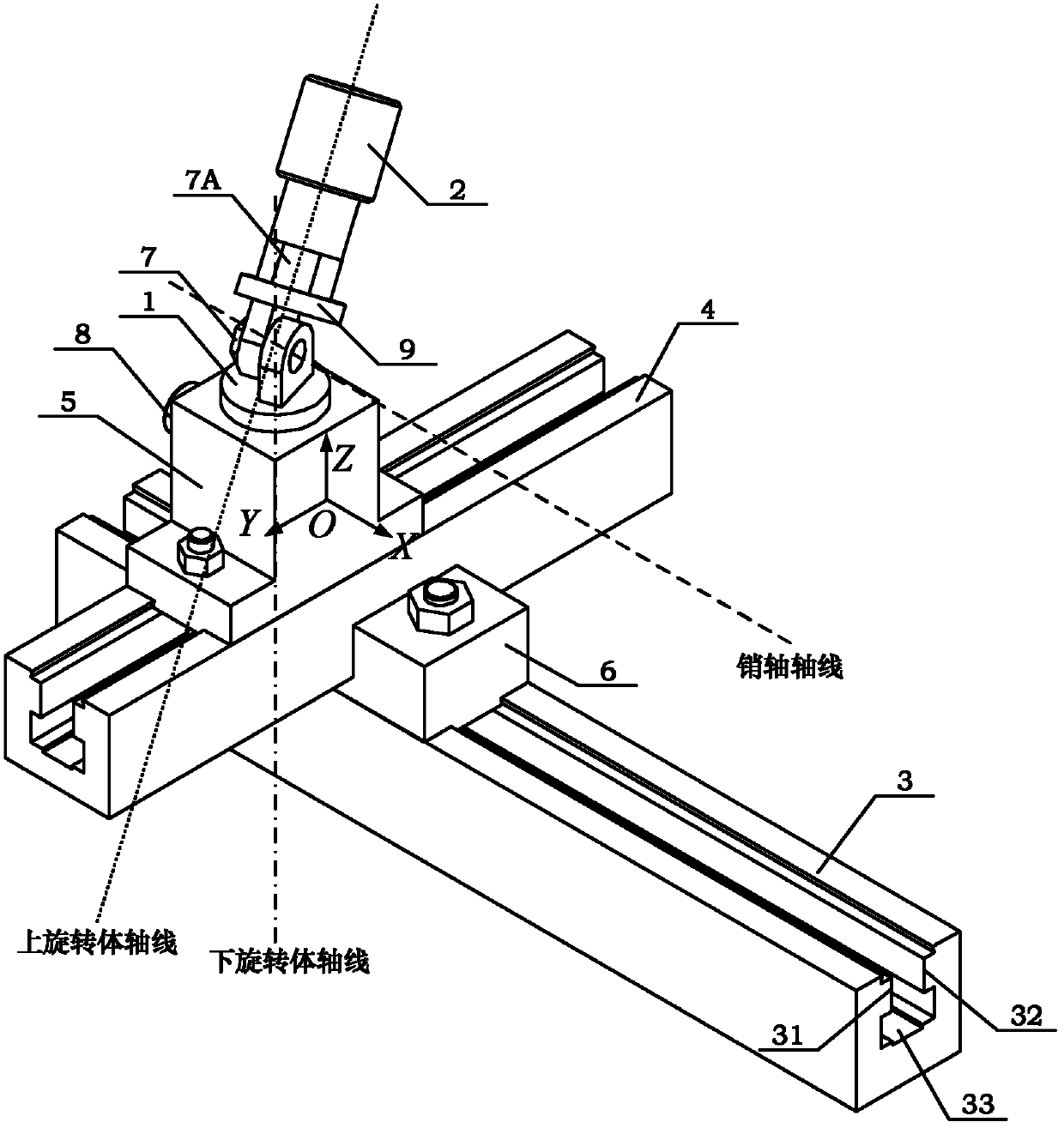

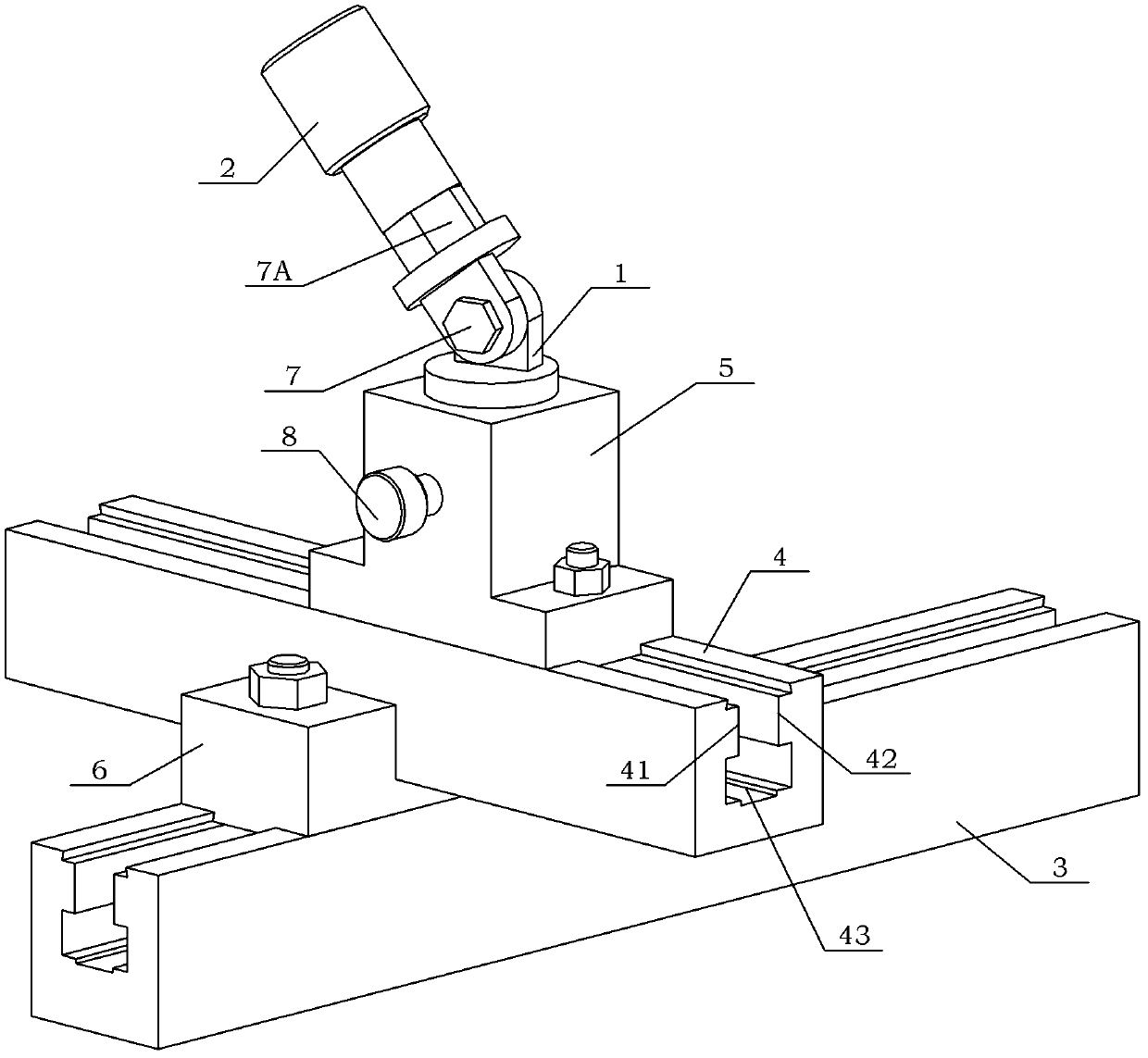

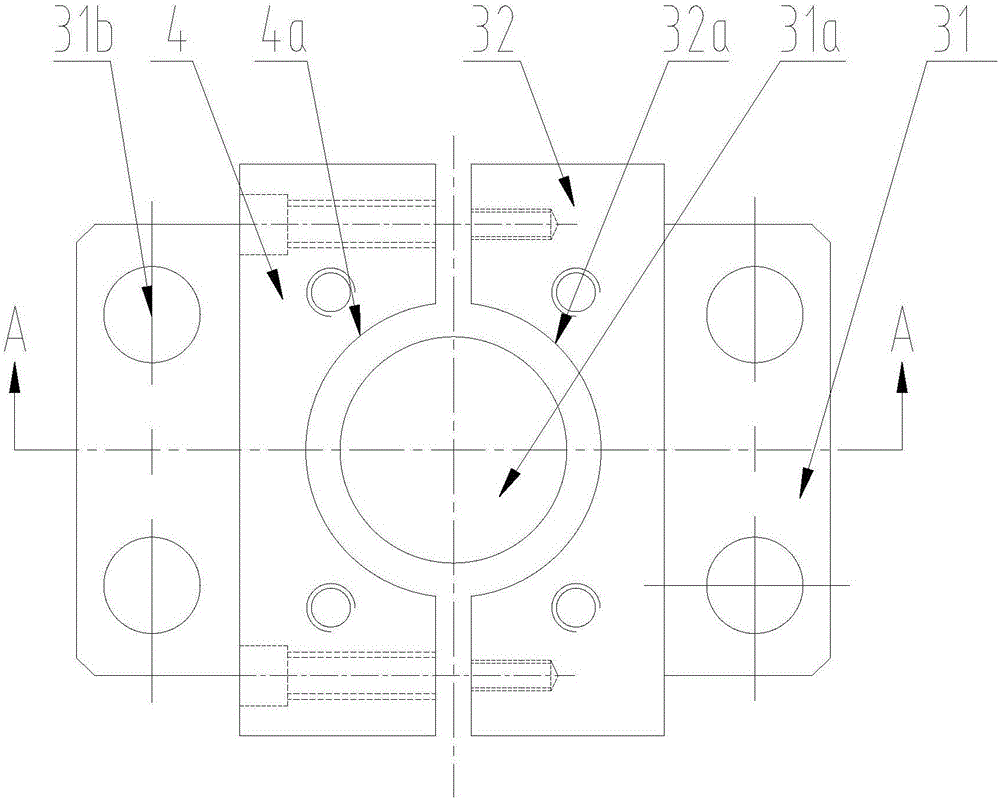

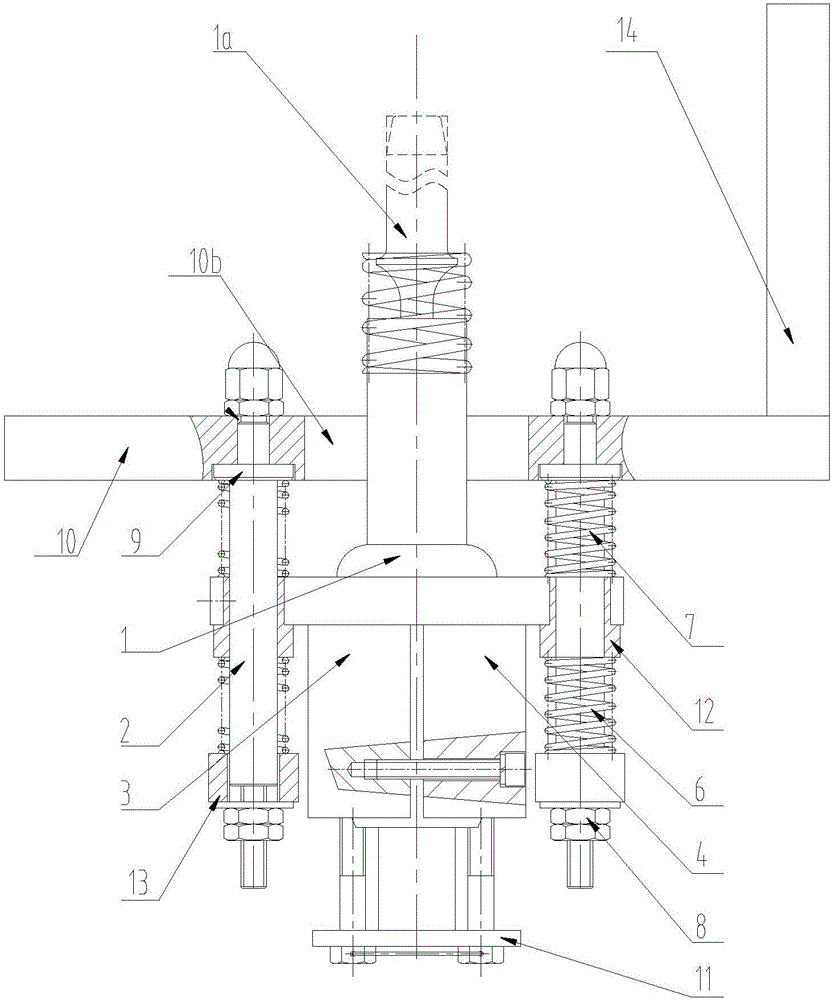

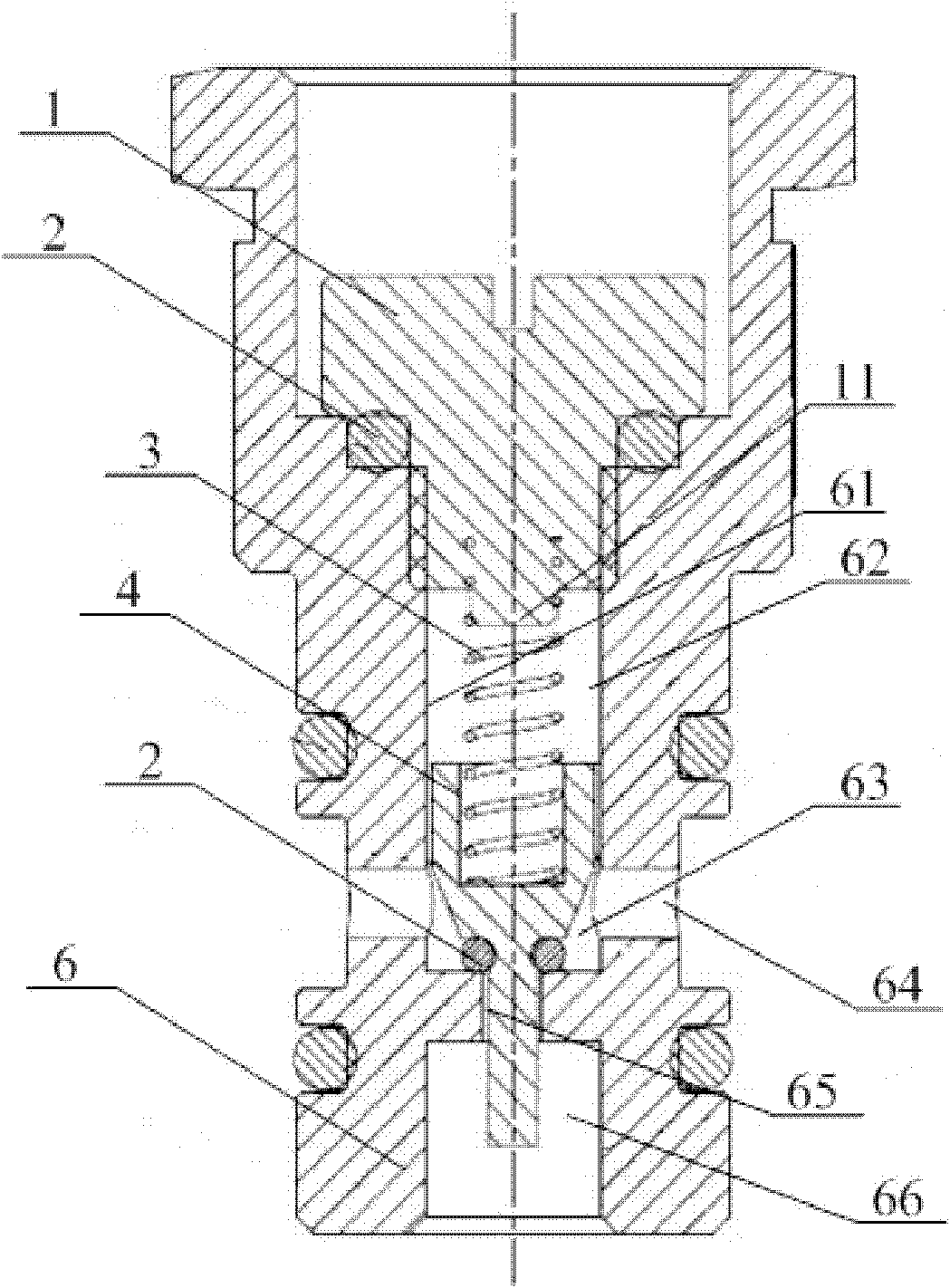

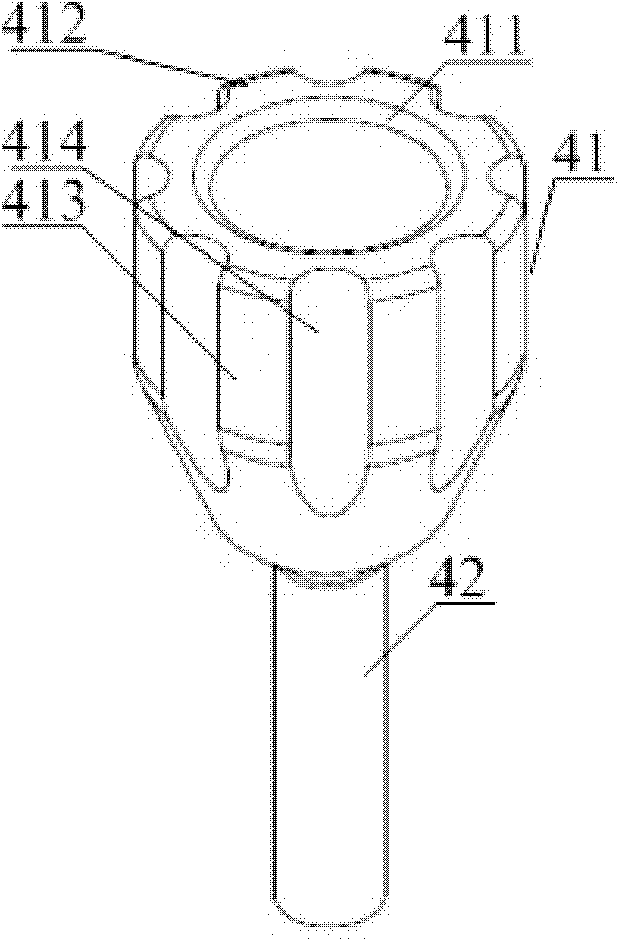

In-situ test positioning controllable mechanical loading and fixing device

InactiveCN102506791AFacilitates axial positioningMove quicklyMeasurement devicesMechanical pressEngineering

The invention discloses an in-situ test positioning controllable mechanical loading and fixing device. A sliding block component (6) of the device is arranged on an X-axis guide rail (3); a sliding block component (6) is arranged on the Y-axis guide rail (4); a sliding base (5) is arranged on the Y-axis guide rail (4); a lower rotating body (1) is arranged on the sliding base (5); the lower rotating body (1) is connected with an upper rotating body (9) by a pin shaft (7); and a clamping cylinder is arranged on the upper rotating body (9). The device disclosed by the invention can quickly and accurately position an irregular experiment sample and can quickly and accurately position the loading site of the experiment sample in situ, thereby greatly reducing the inaccurate positioning problems aroused by the drawbacks of a loading device in an experiment process and improving the accuracy and repeatability of the in-situ test positioning by a mechanical press-in method.

Owner:BEIHANG UNIV

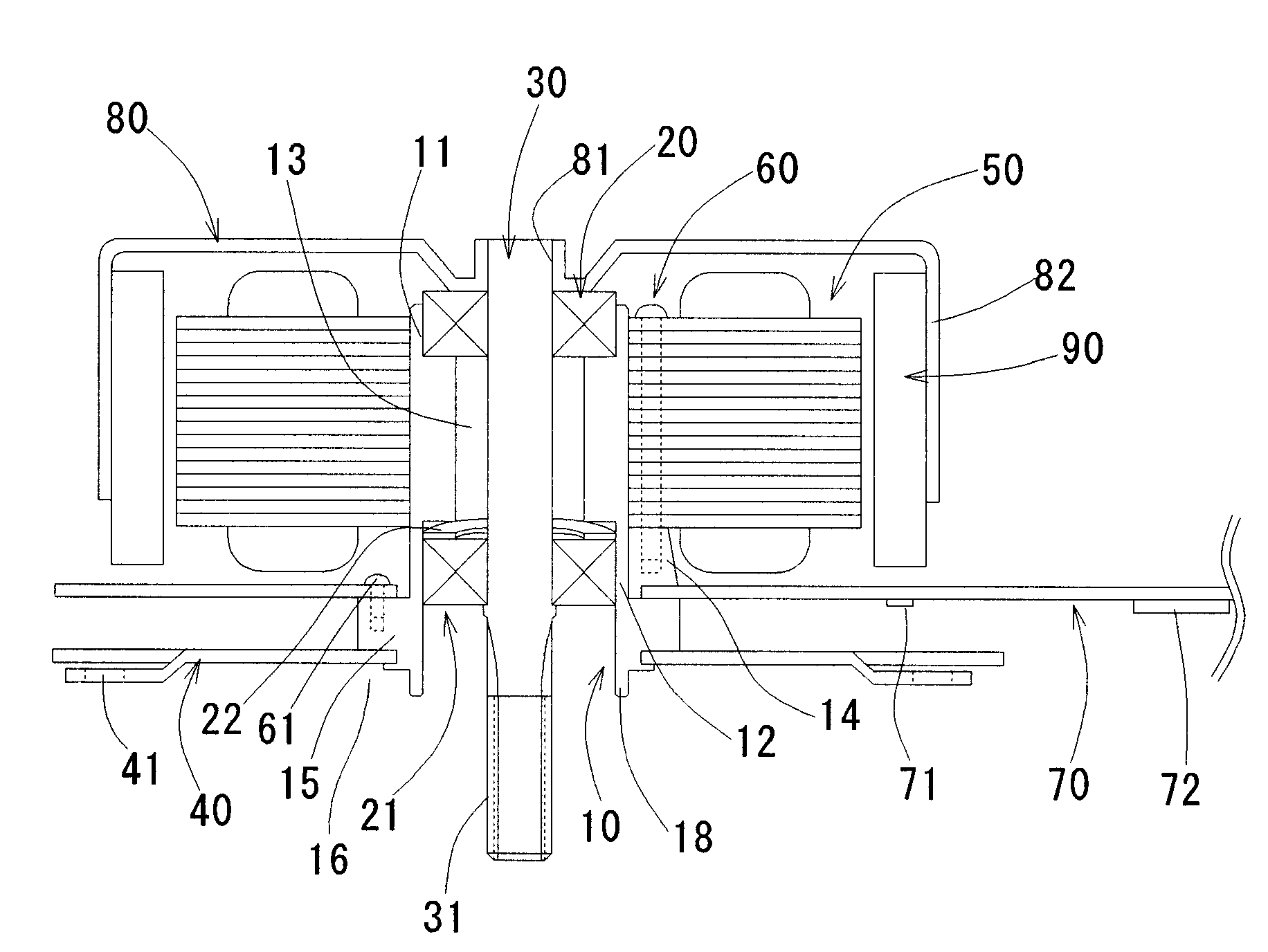

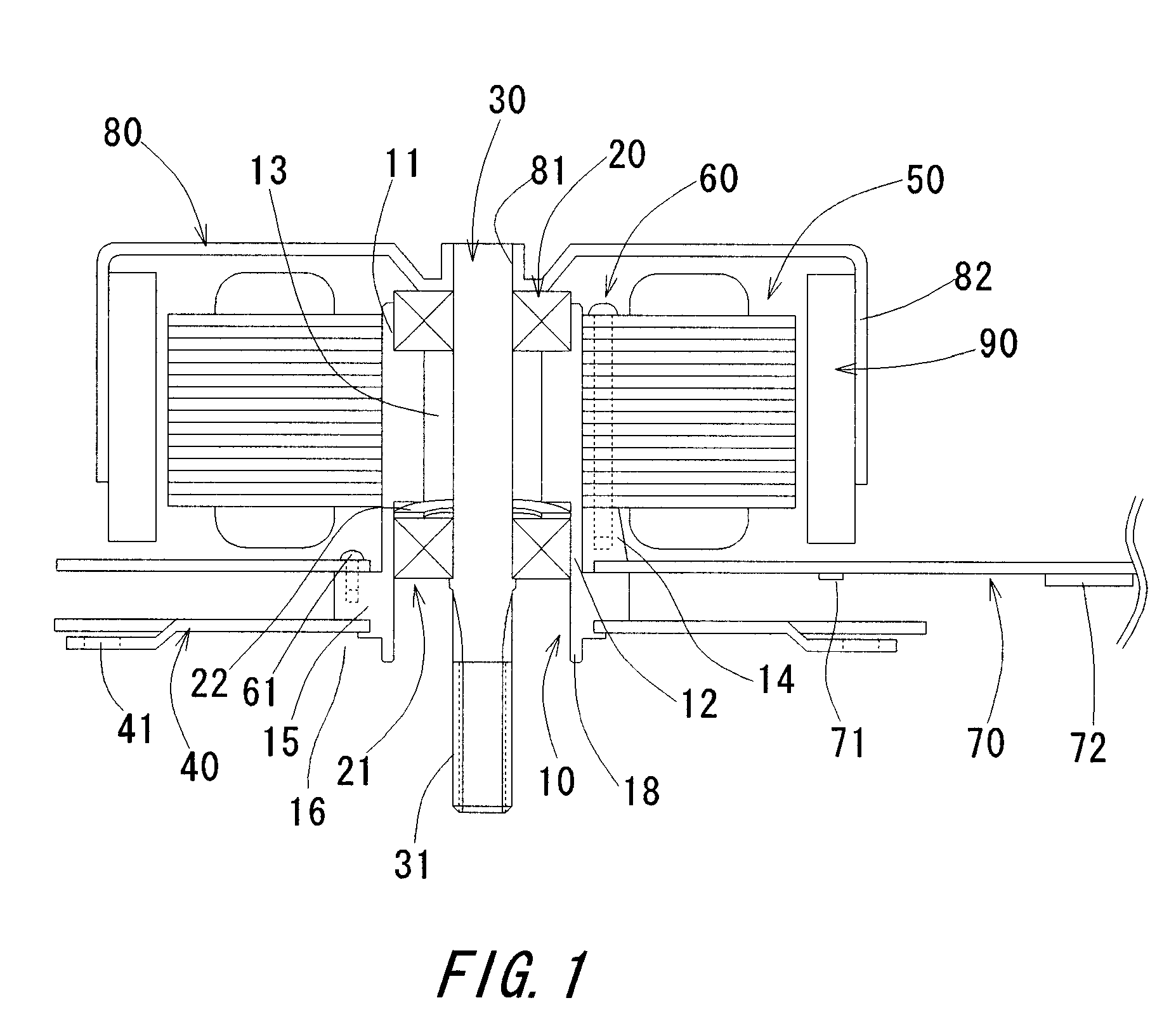

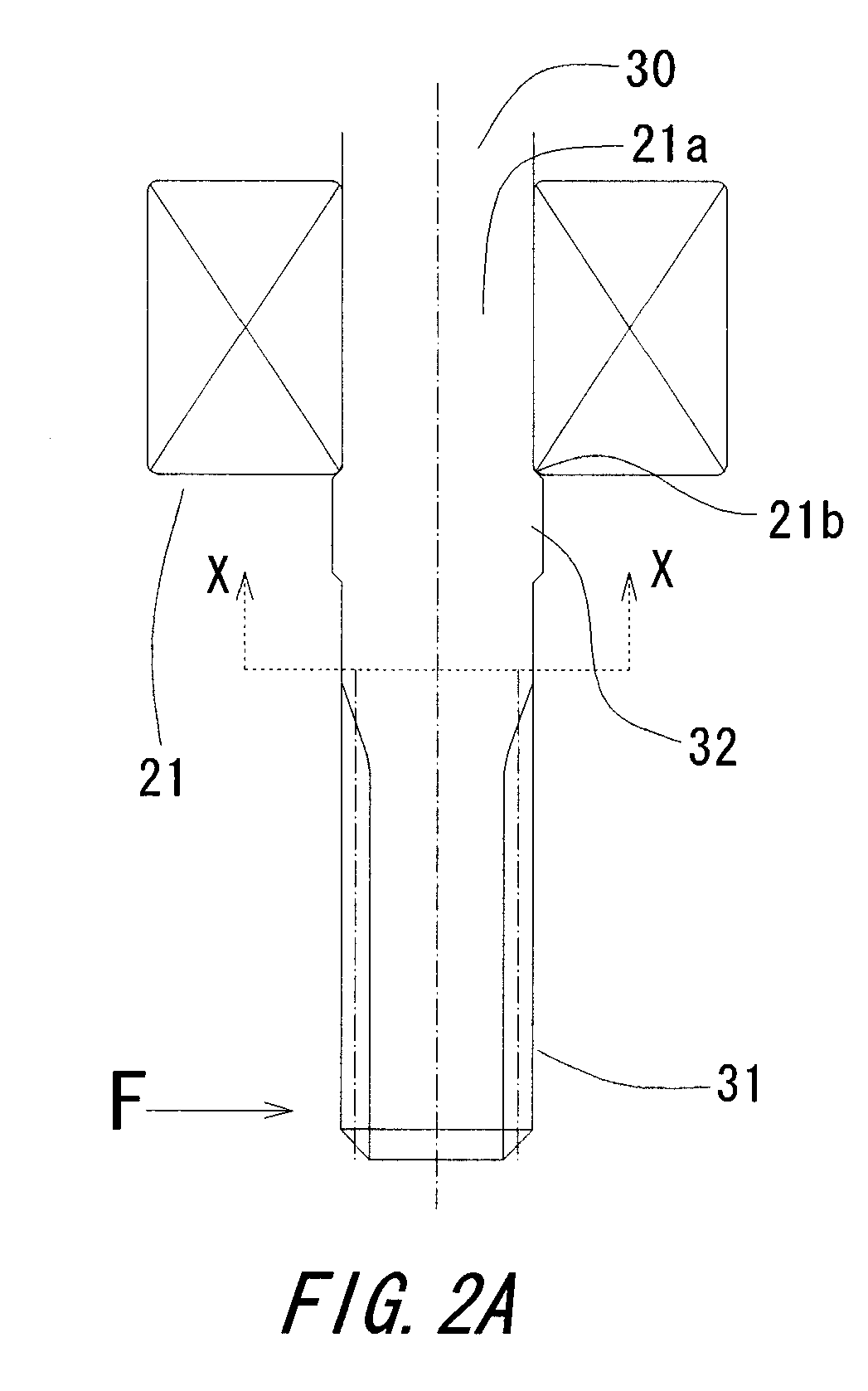

Brushless motor

InactiveUS20070114863A1Efficient preparationReliable and durable brushlessMagnetic circuit rotating partsMechanical energy handlingBrushless motorsBall bearing

A shaft of a brushless motor includes a protruding portion, and a ball bearing abutting against the protruding portion for axially positioning the ball bearing. The protruding portion is formed by rolling, and a plurality of protruding portions are arranged on the shaft in a circumferentially equally spaced manner. By forming the protruding portions by rolling, durability of the shaft against a force in a radial direction is enhanced, and therefore, it is possible to provide a reliable brushless motor.

Owner:NIDEC CORP

Automobile axial overturn fixture

Owner:新昌县万星制冷配件有限公司

Metallic seal solvable bridge plug

Owner:FIVE STAR DOWNHOLE SERVICE INC

Forging machining process of parking gear

PendingCN112404914AReduce material wasteIncrease productivityMetal-working apparatusMachining processManufacturing engineering

The invention discloses a forging machining process of a parking gear, and relates to the technical field of gear machining. The problems that parking gear machining production efficiency is low, andmaterial waste is serious in the prior art are solved. The machining process comprises the following steps of blanking, outer circle turning, heating, blank making, center hole punching, hot precisionforging, connected skin turning, isothermal normalizing, shot blasting, scale saponification and cold extrusion. The forging process is adopted for parking gear machining, material waste is reduced,a cavity is machined through preforming, and a cake-shaped structure is formed through common preforming. An annular structure with a taper step is adopted and adapts to a product, and when a blank ismachined into the cavity, the peripheral wall of the opening end of the cavity is expanded outwards and inclines to form an opening face, the opening face horizontally extends towards the end face ofa cylindrical body to penetrate through the end face of the cylindrical body, and accordingly, a positioning boss is formed, axial positioning of a die and the blank is facilitated, and the subsequent forging quality is guaranteed. Through the design of the cavity, the forging force requirement of precision forging forming can be reduced.

Owner:SICHUAN ZHONGYOU MACHINERY

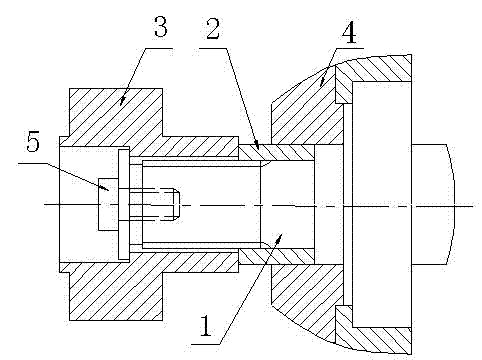

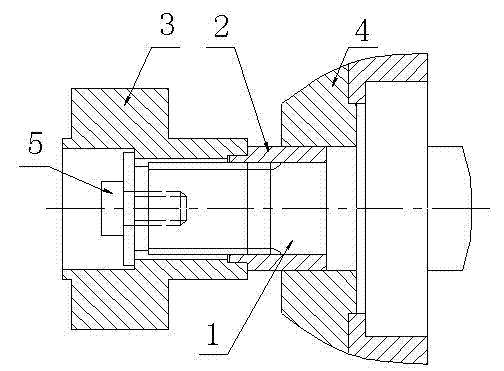

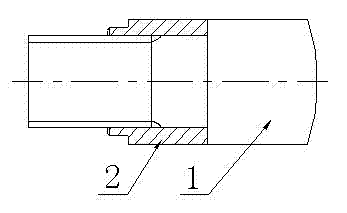

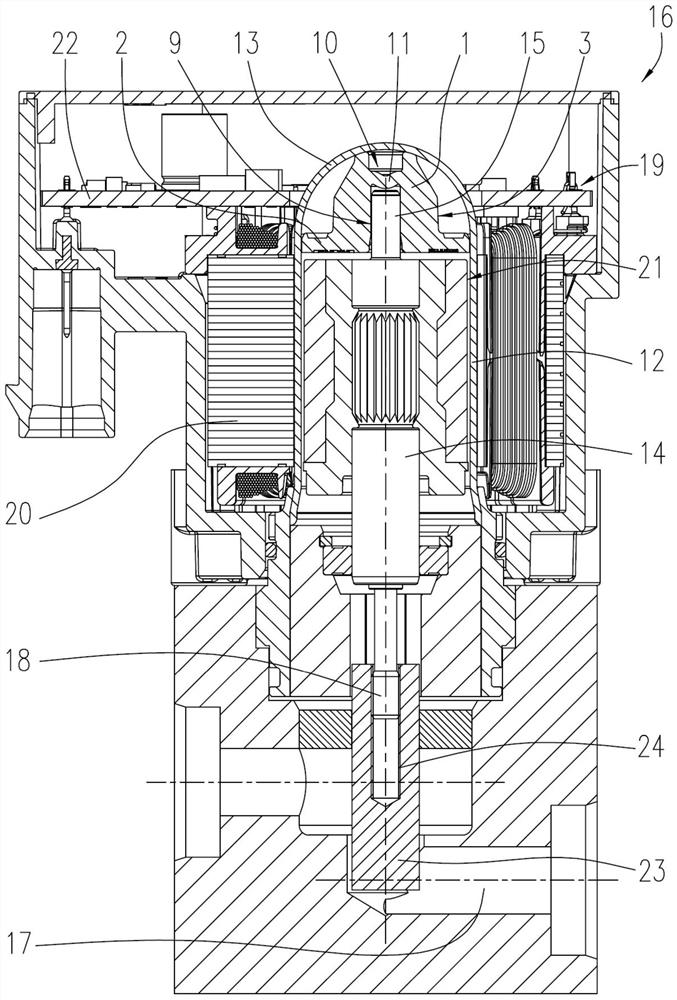

Connecting method of pure electrical vehicle driving system

InactiveCN102211520AAxial positioning is accurateAvoid stress concentrationControl devicesElectric machineryProcessing accuracy

The invention discloses a connecting method of a pure electrical vehicle driving system, comprising the following steps of: A, processing a motor rotor main shaft (1); B, processing a spline sleeve (2); C, processing a connecting flange (3); and D, connecting and assembling. The method has the advantages of accuracy and convenience in positioning, high processing precision, and little error; the matching quality of connecting pieces is ensured; and the whole system is stable in running.

Owner:DONGFANG ELECTRIC CORPLESHAN NEW ENERGY EQUIP

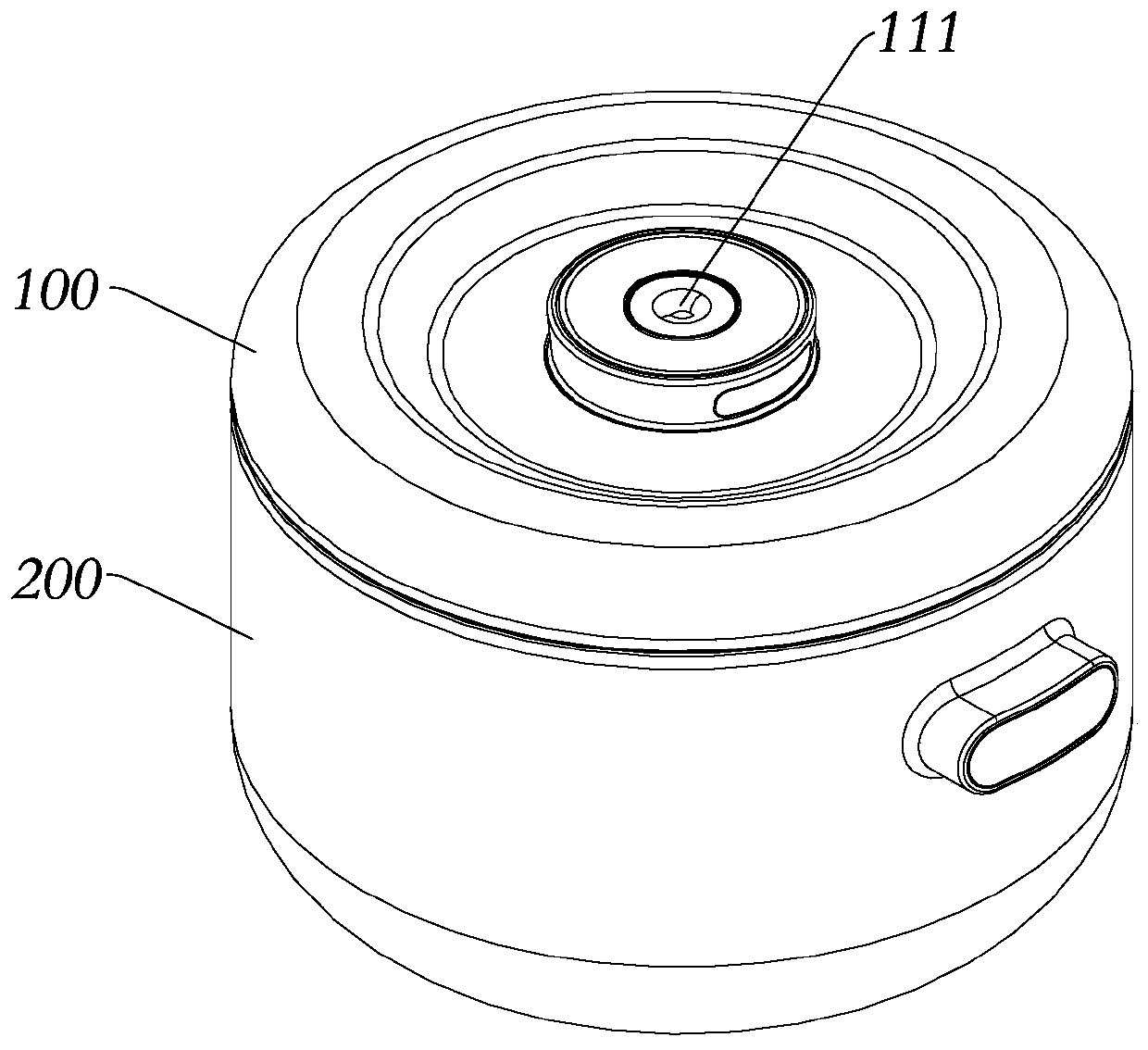

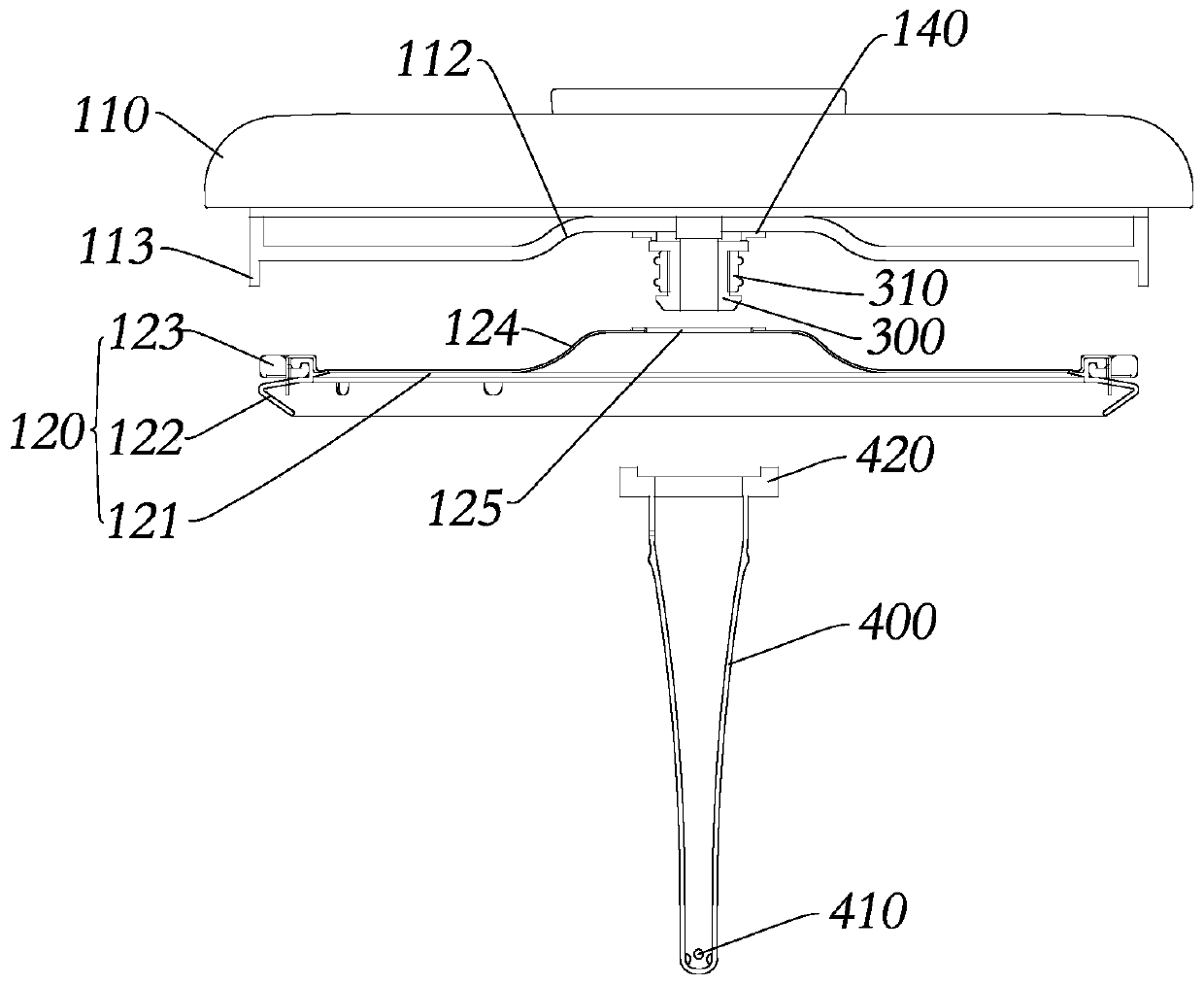

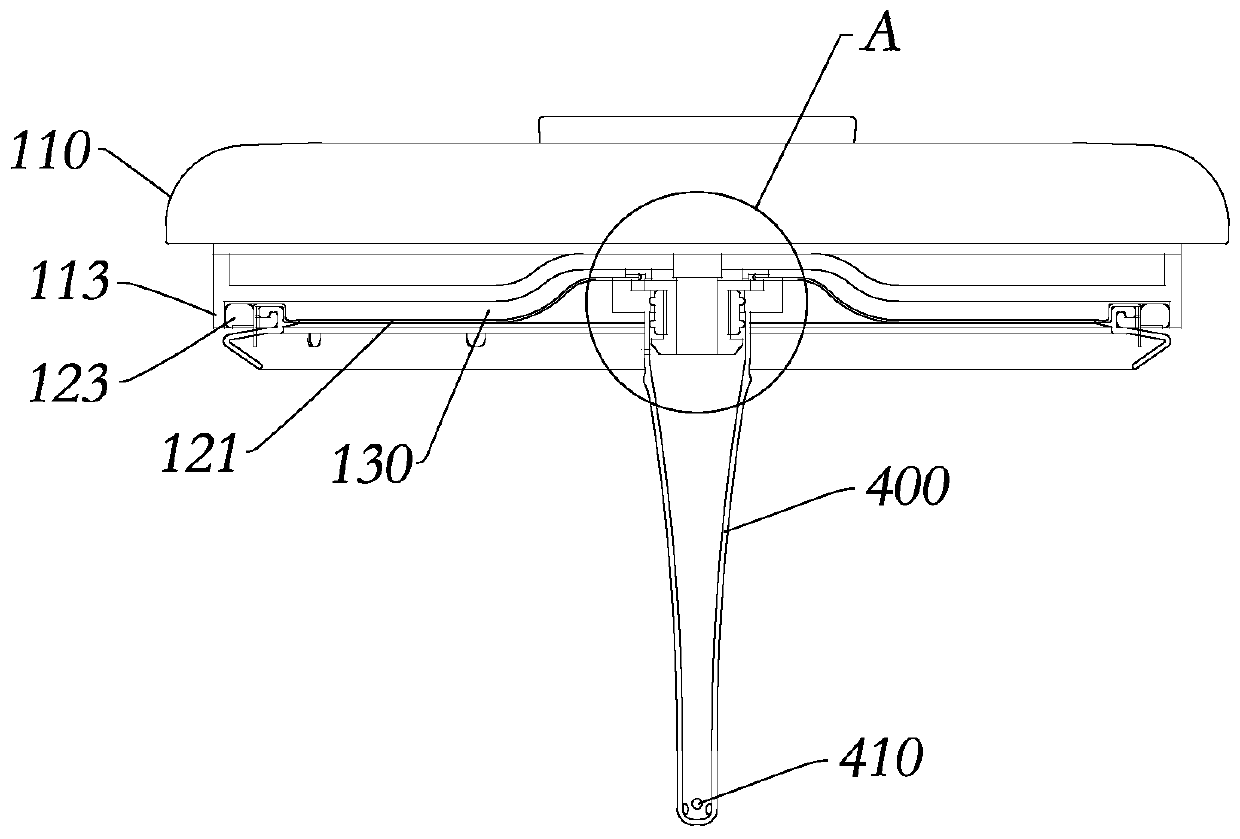

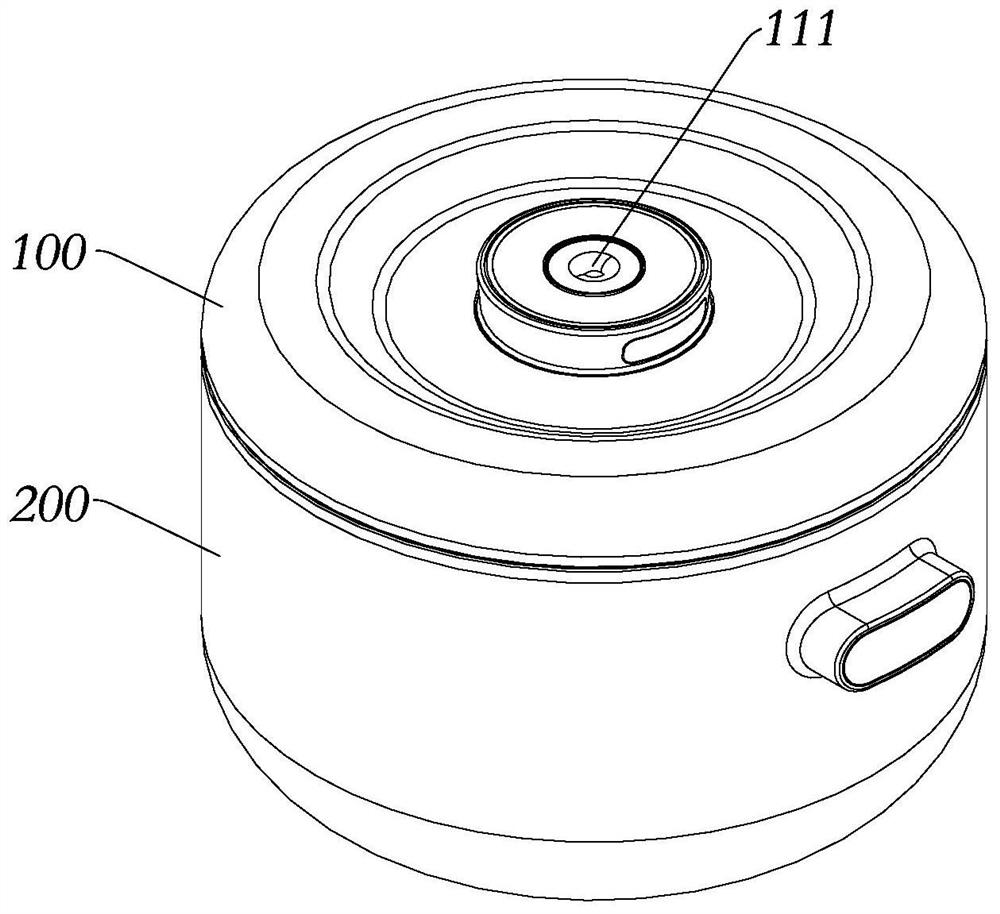

Cooking pan using steam heating, and steam heating type cooking utensil

ActiveCN110338641AExtend your lifeReduce entryBoiling over preventionCooking-vessel lids/coversEngineeringSteam heating

The invention discloses a cooking pan using steam heating, and a steam heating type cooking utensil, belongs to the field of kitchen household appliances, and solves the problem that a pan cover of acooking pan in the prior art is inconvenient to clean. The cooking pan provided by the invention comprises a pan body and a pan cover, wherein the pan cover comprises an outer cover and an inner cover; the outer cover covers the pan edge of the pan body; and the inner cover and the pan body are matched to form a cooking chamber. The cooking pan further comprises a steam guide pipe, wherein a projected air inlet connector is arranged on the inner side of the outer cover and penetrates through the inner cover; and the steam guide pipe can be detachably arranged on the air inlet connector and axially positions the inner cover. The cooking pan provided by the invention adopts the design of the detachable inner cover, so that the inner cover can be conveniently and independently cleaned.

Owner:JOYOUNG CO LTD

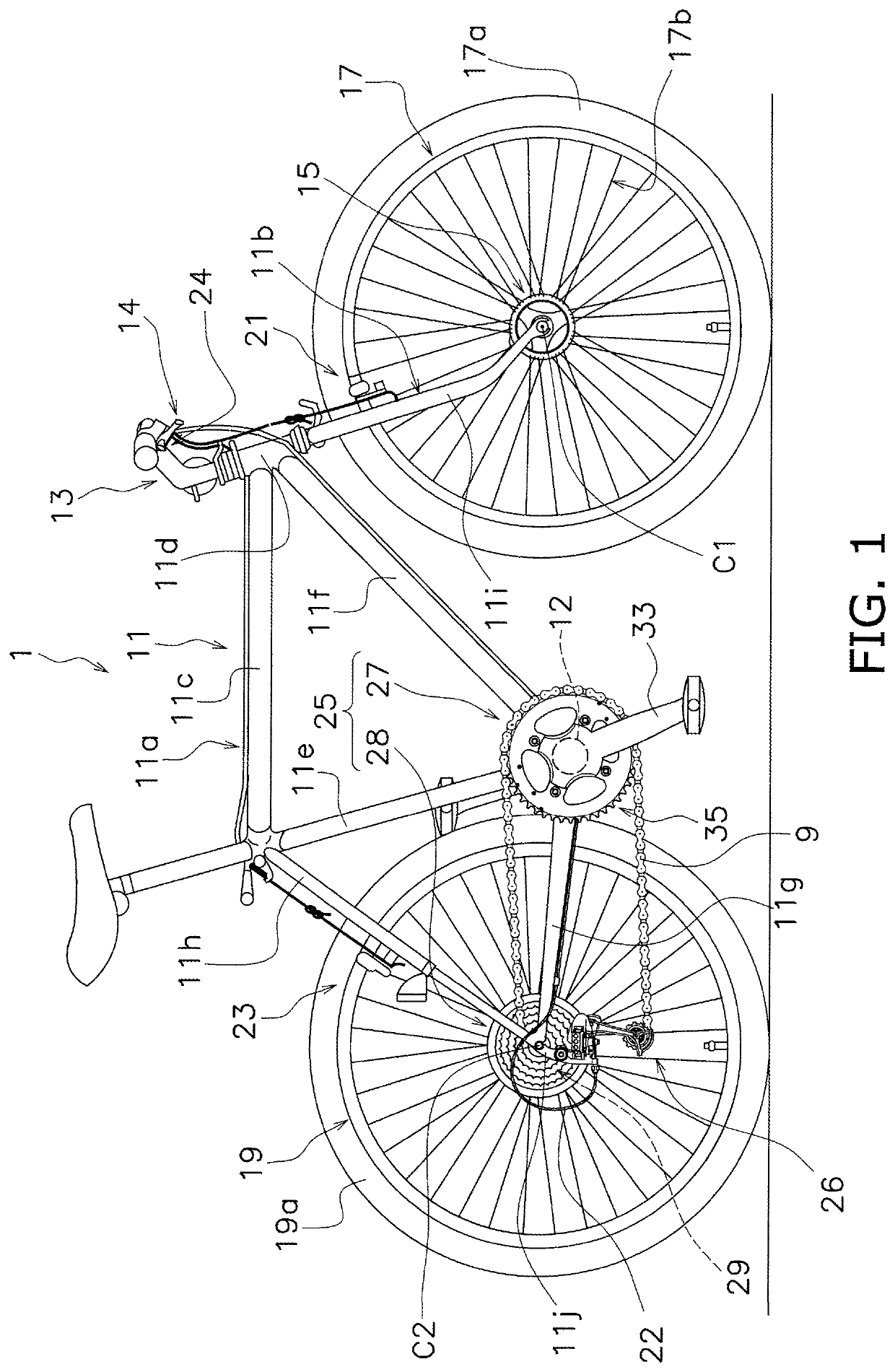

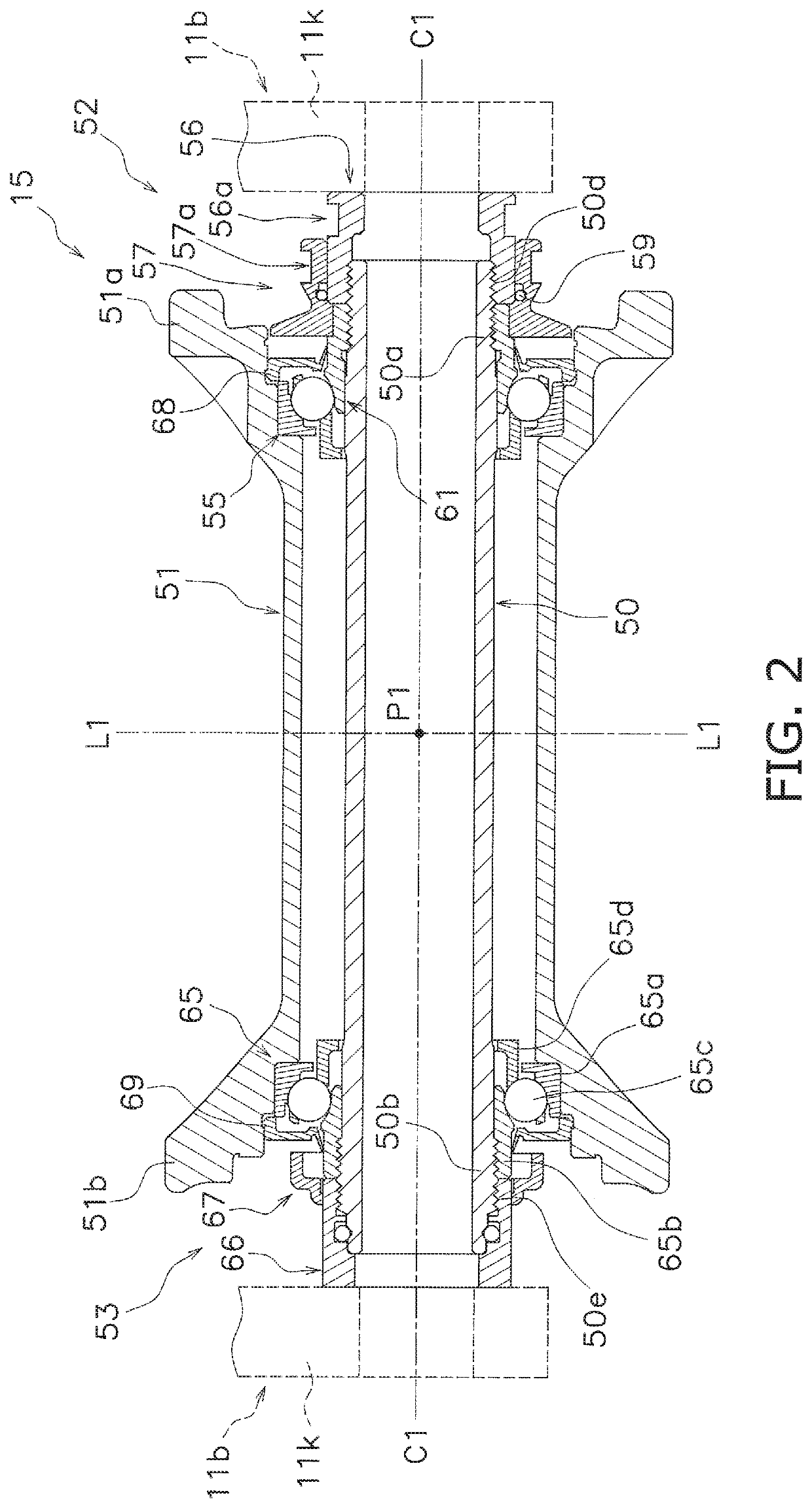

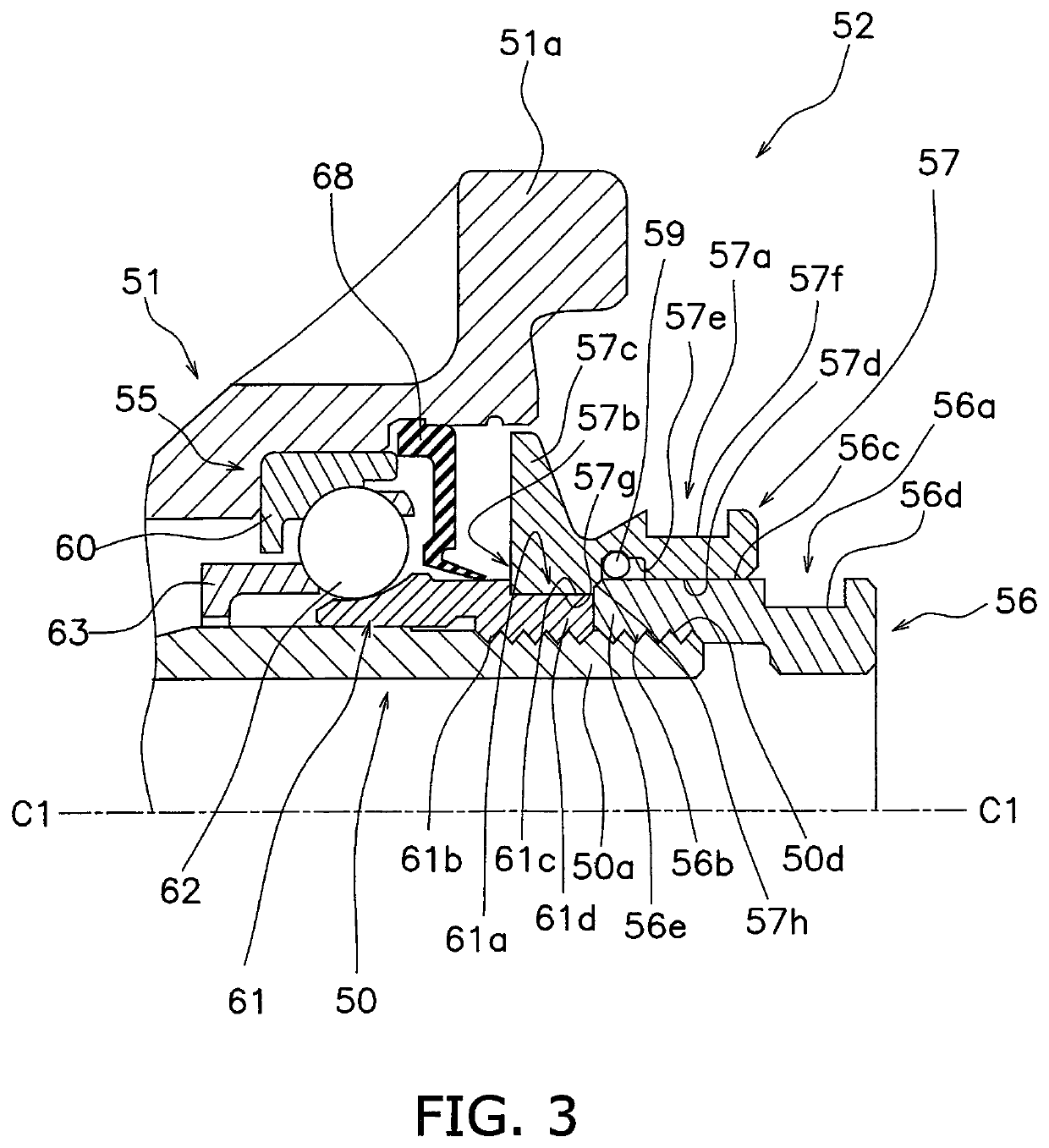

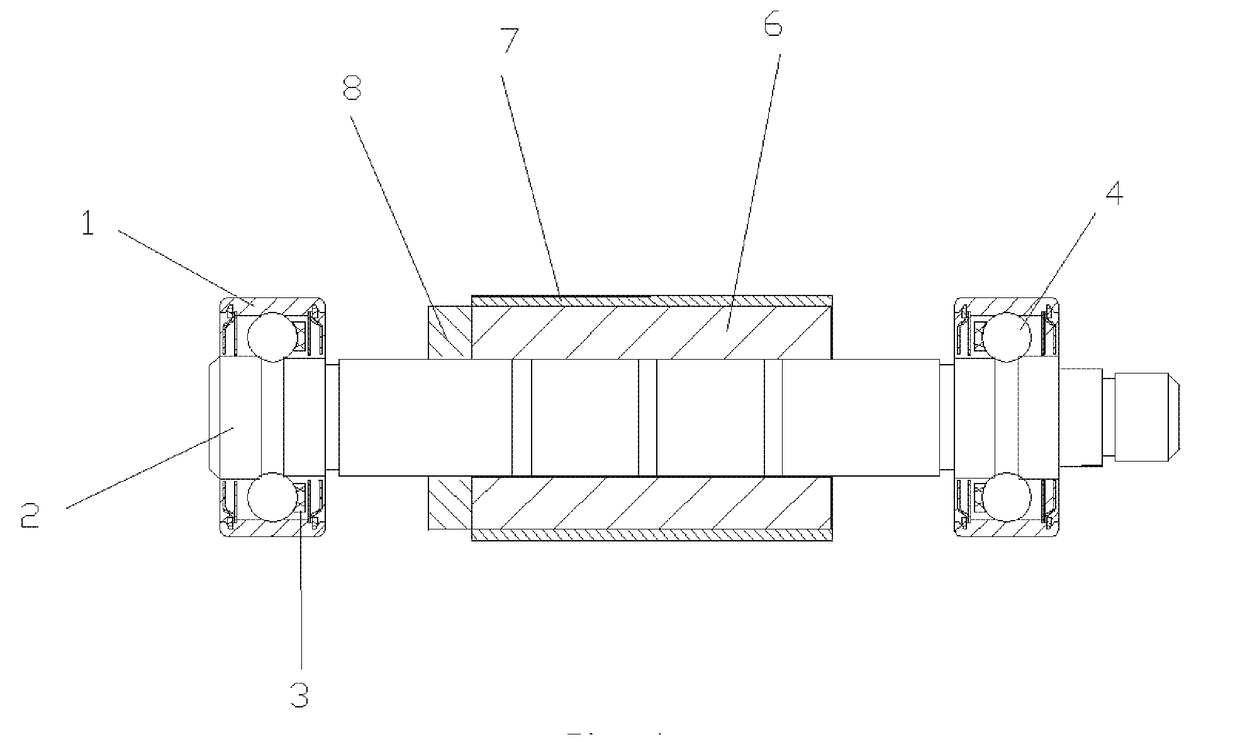

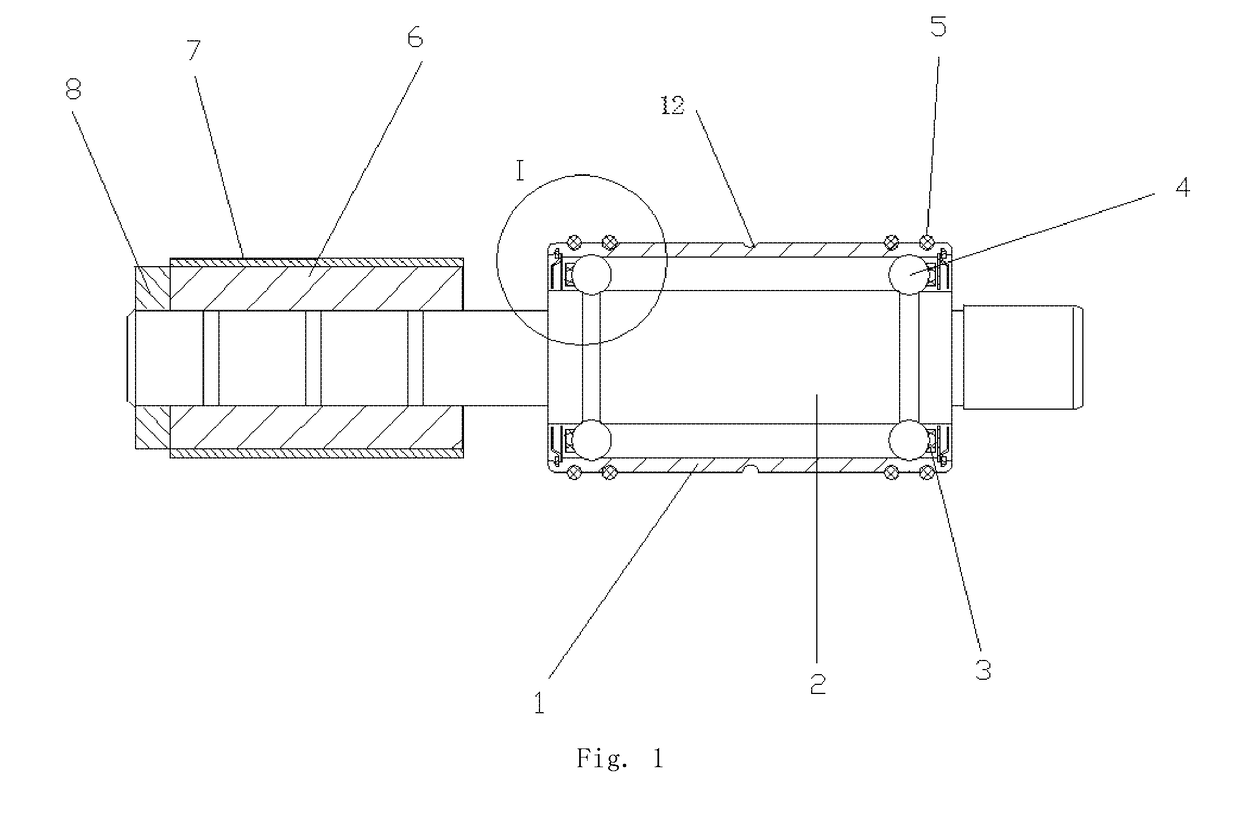

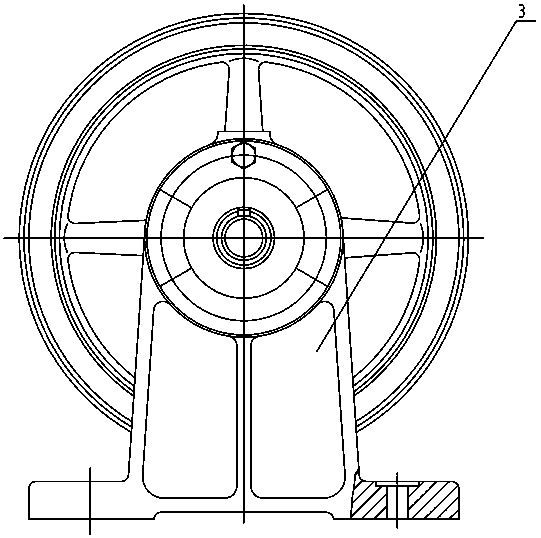

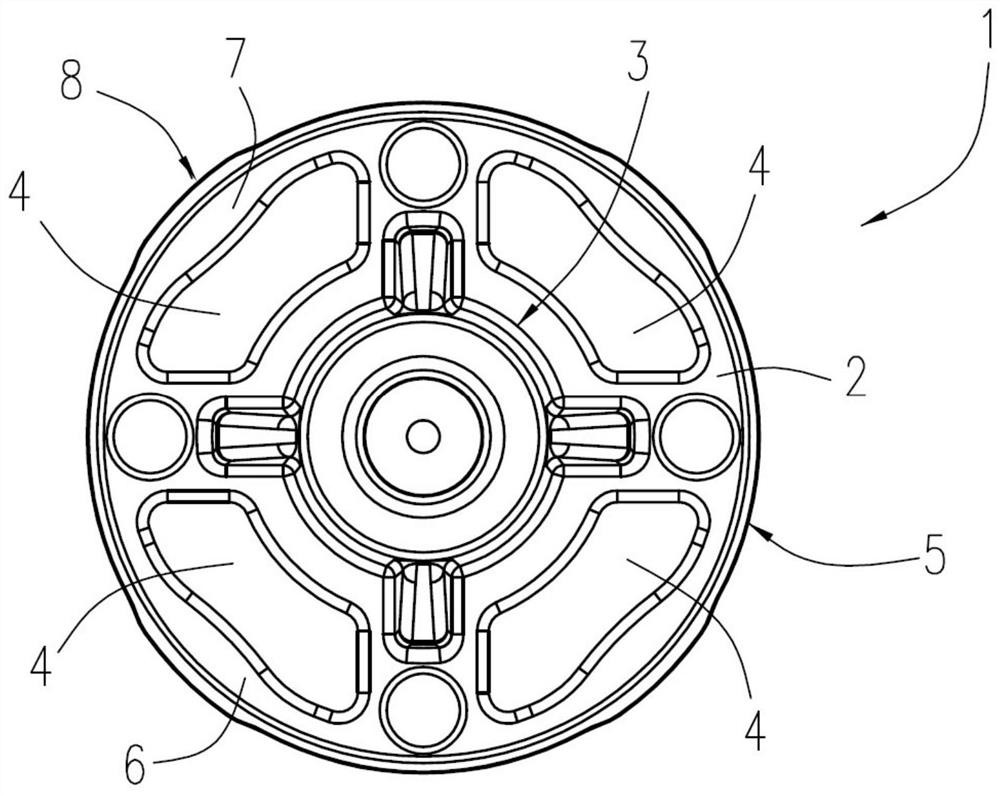

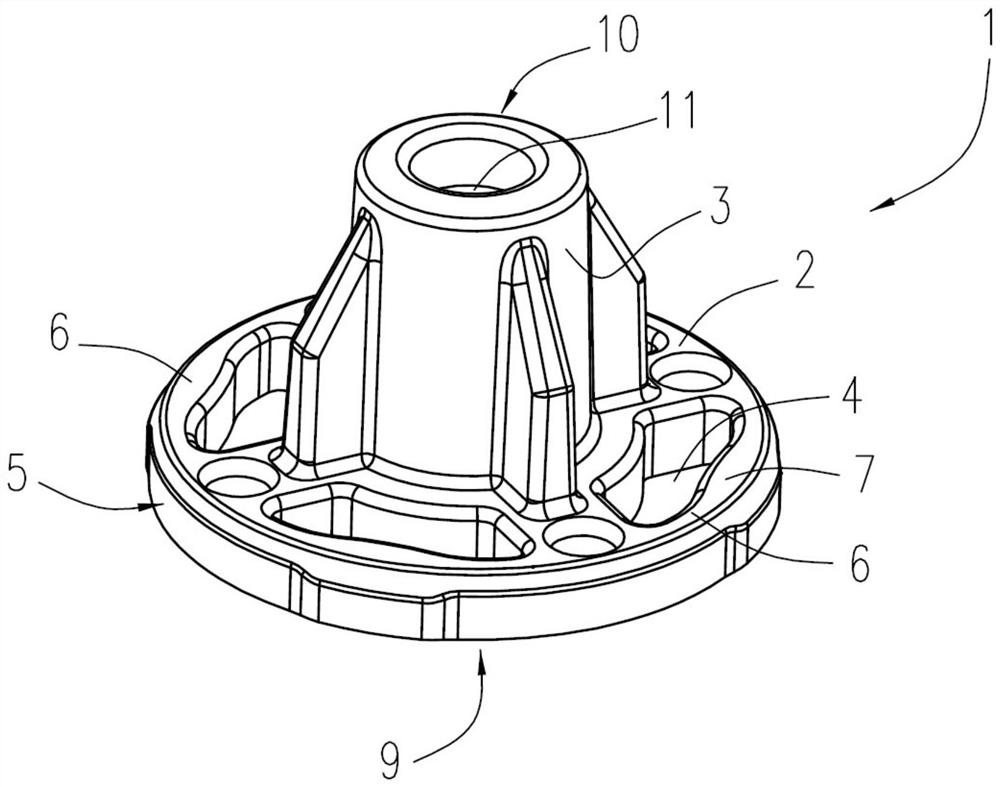

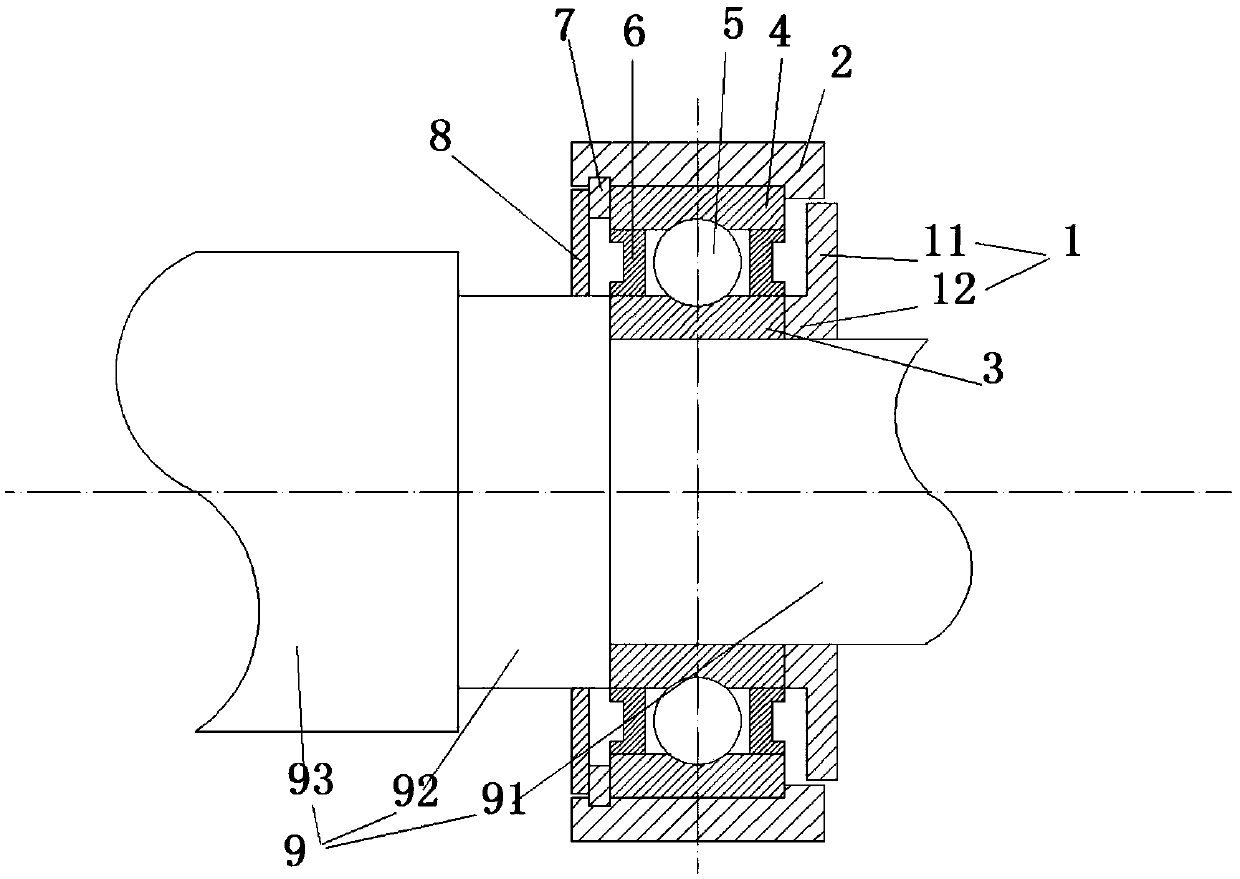

Bicycle hub assembly

ActiveUS10654314B2Prevent rotationFacilitates axial positioningHubsWheel assembling toolsCentre of rotationStructural engineering

The bicycle hub assembly includes a hub axle, a hub body, a bearing unit, a lock member, and a tool engagement member. The bearing unit is configured to rotatably support the hub body around the hub axle with respect to the rotational center axis. The bearing unit includes an outer race, an inner race and a plurality of rolling members. The lock member prevents the inner race of the bearing unit from rotating relative to the hub axle. The tool engagement member is configured to rotate the inner race of the bearing unit relative to the hub axle.

Owner:SHIMANO INC

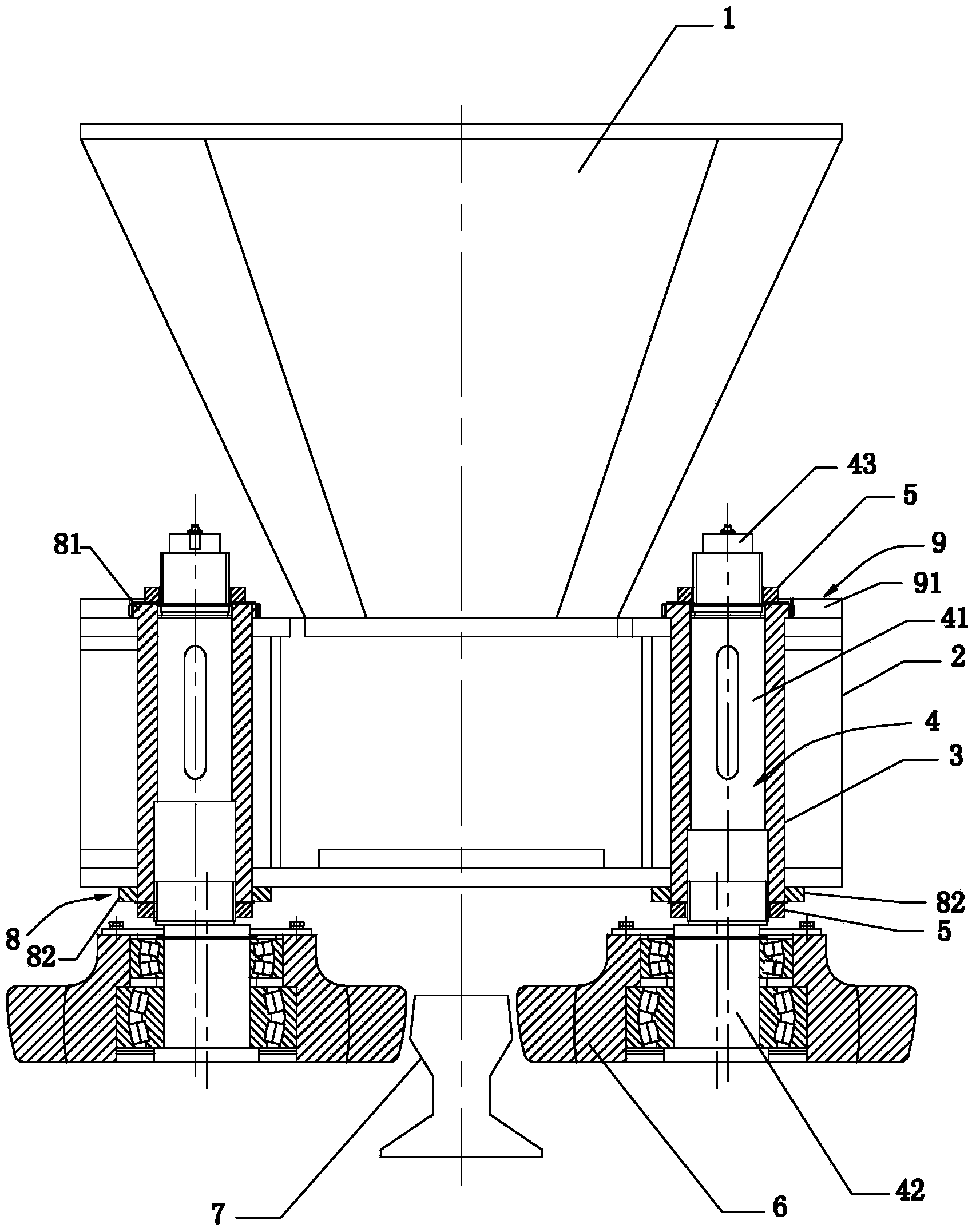

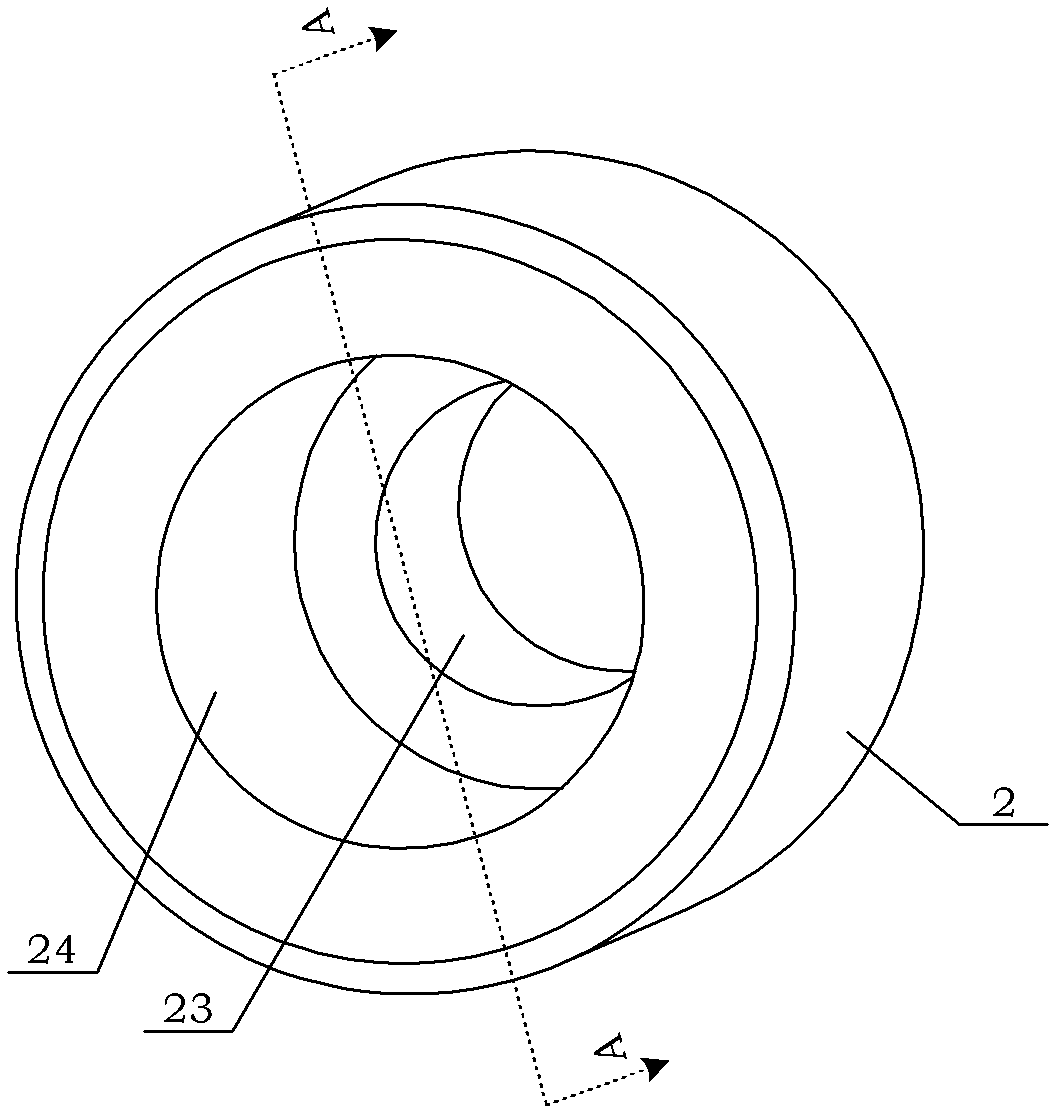

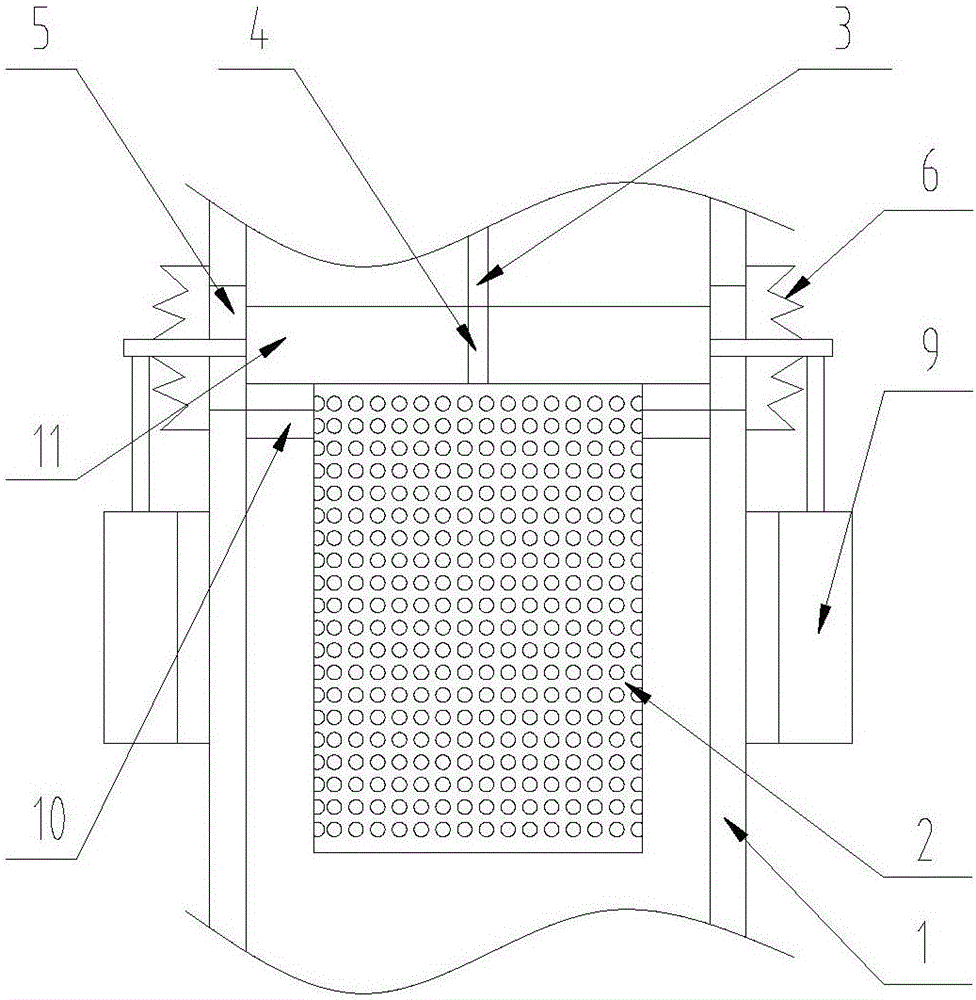

Concrete pump with vibration type hopper fence

InactiveCN106640127AFacilitates axial positioningEasy clampingUnderground chambersFoundation engineeringEngineeringConcrete pump

The invention discloses a concrete pump with a vibration type hopper fence. By adoption of the concrete pump, the problem of concrete accumulation is thoroughly solved. The concrete pump comprises a concrete stirring device, a hopper, the fence and a vibration device which comprises a pneumatic vibrator, a device used for clamping the pneumatic vibrator, and guide rods. The device used for clamping the pneumatic vibrator comprises a base plate, a clamping base and clamp pincers. The base plate is provided with a receding through hole. The clamping base is fixed to the lower end face of the base plate. The clamping pincers are fastened to the clamping base through screws to fix the pneumatic vibrator. An impact rod of the pneumatic vibrator extends upwards to penetrate through the receding through hole to be connected with the fence. The base plate is provided with a plurality of guide rod passing holes to be slidably matched with the guide rods. The upper extending ends and the lower extending ends of all the guide rods are separately sleeved with upper and lower compression springs which are axially fixed. The upper ends of all the guide rods are connected to a connecting plate which is fixed to the hopper. A mounting plate is provided with a receding passing hole used for allowing the impact rod of the pneumatic vibrator to penetrate through and extend out.

Owner:重庆华耀混凝土有限公司

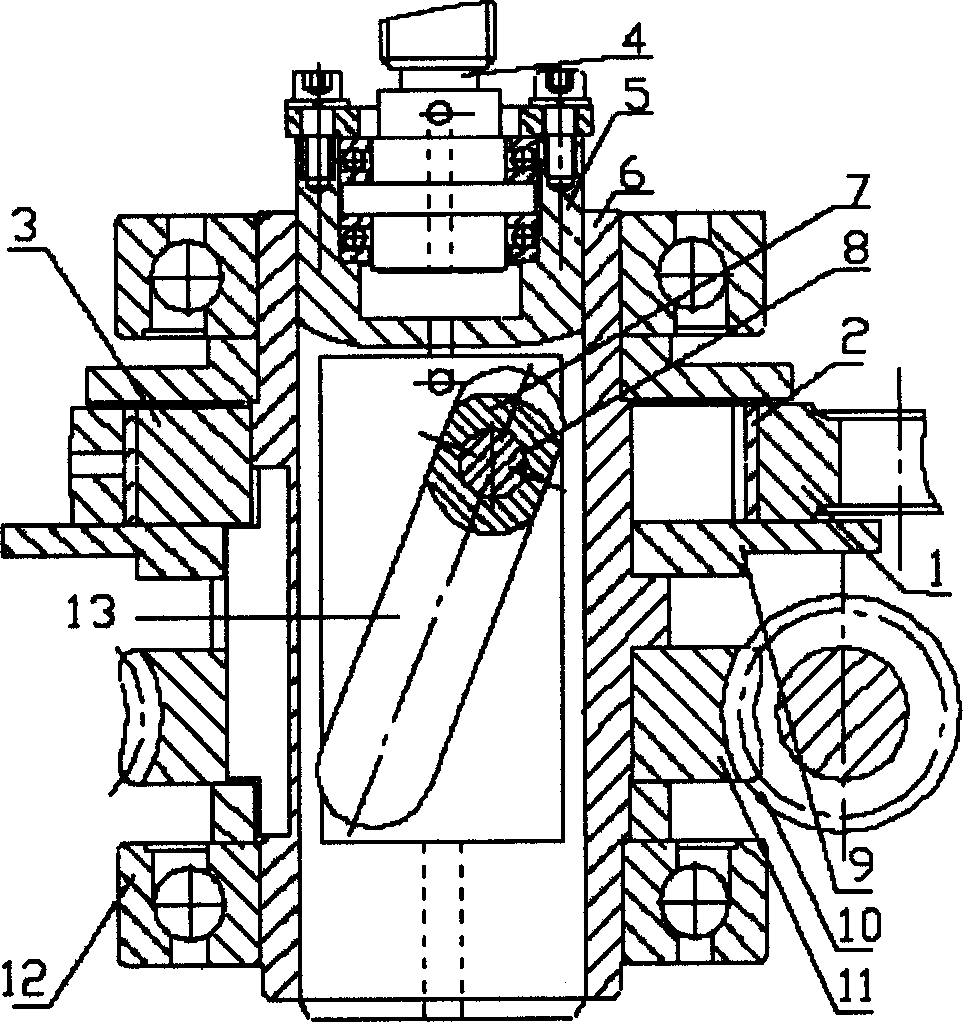

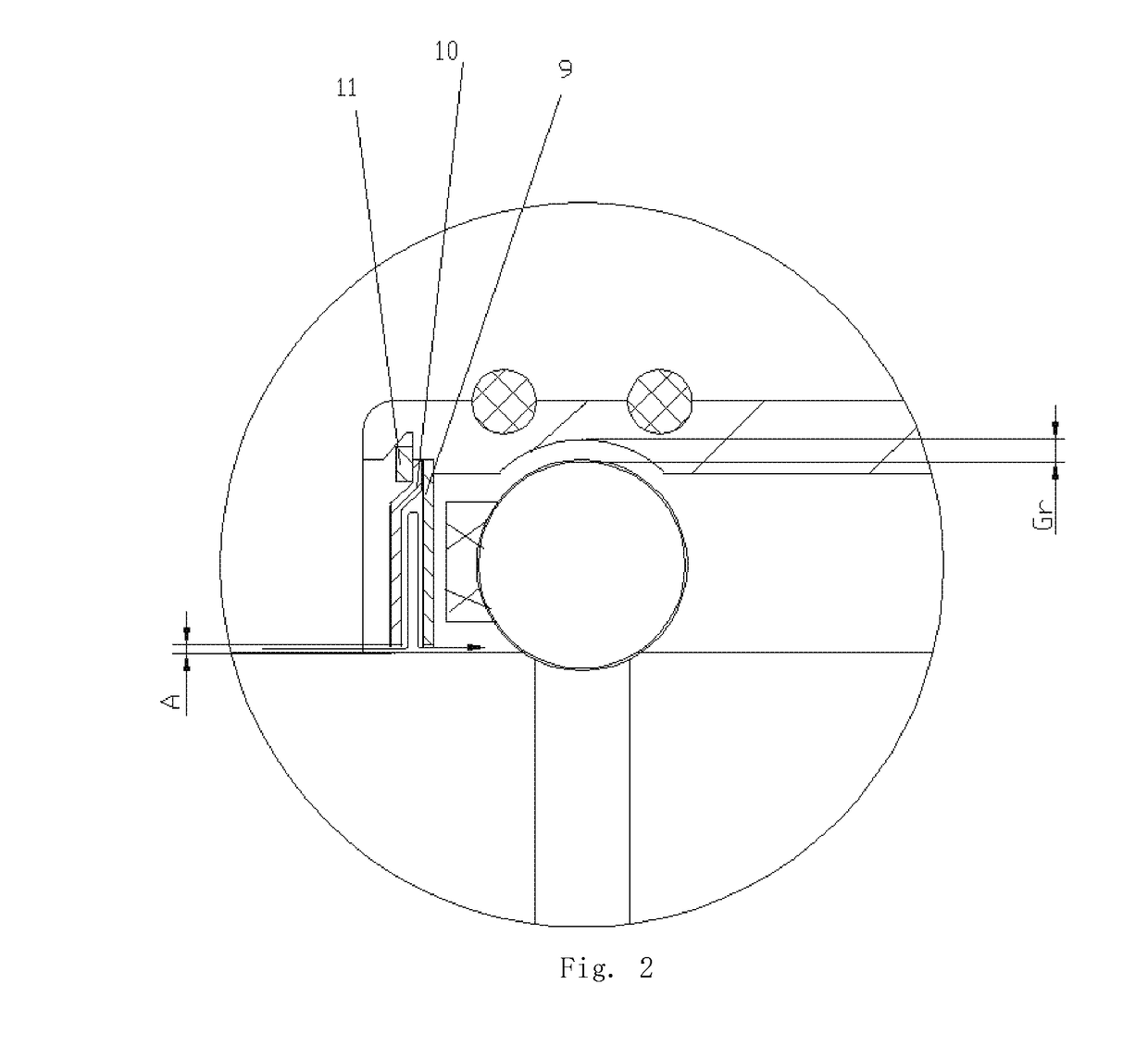

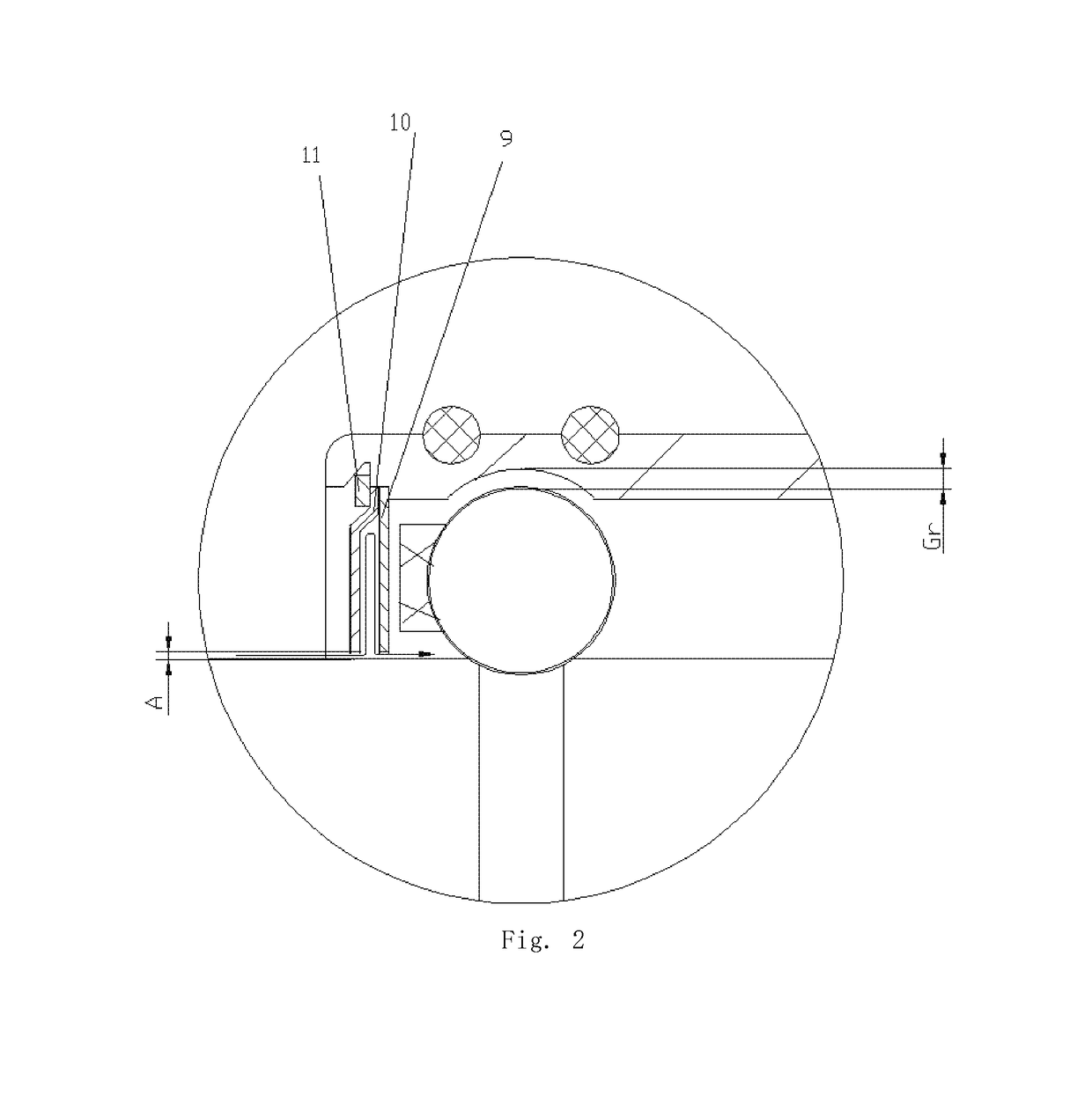

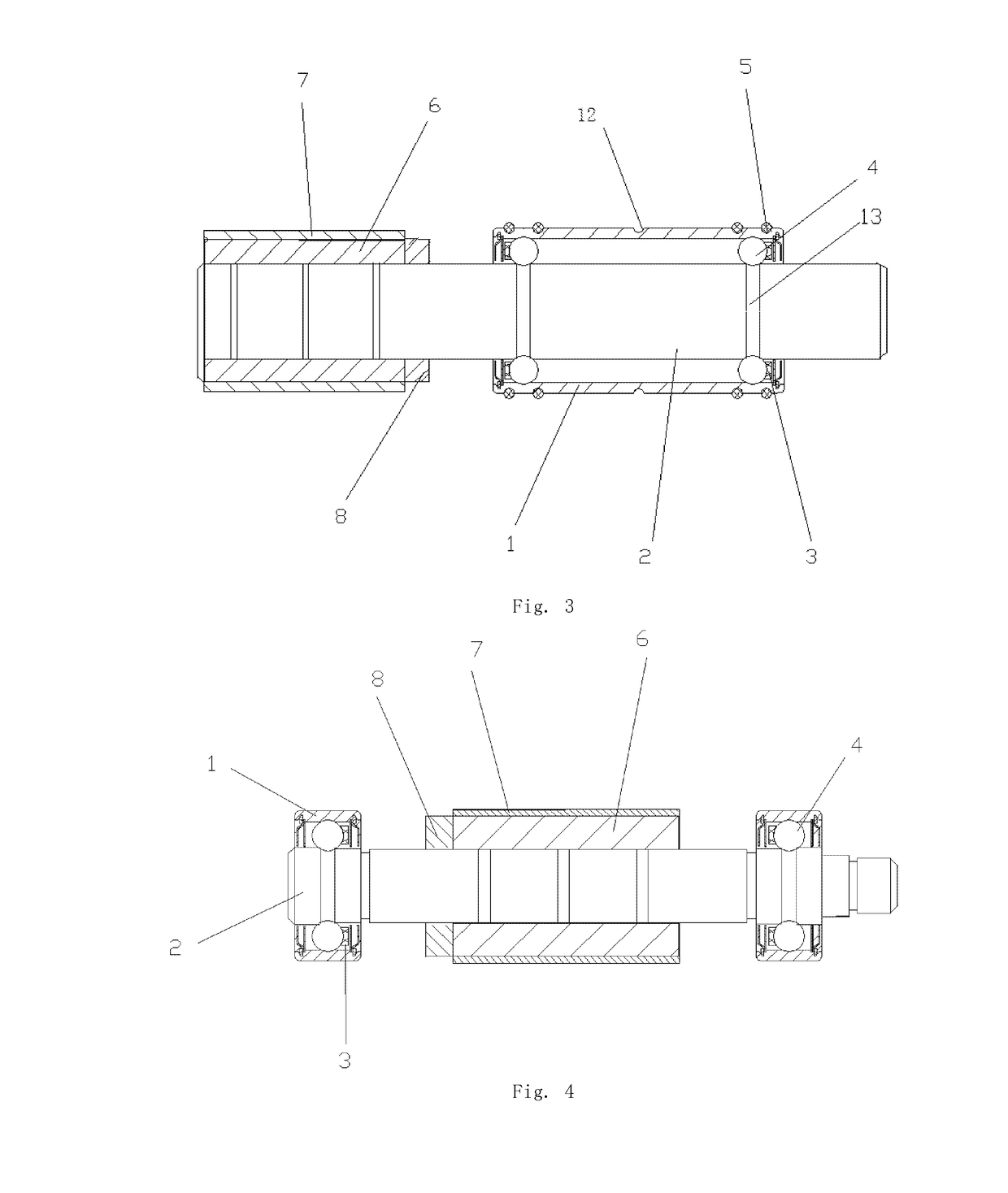

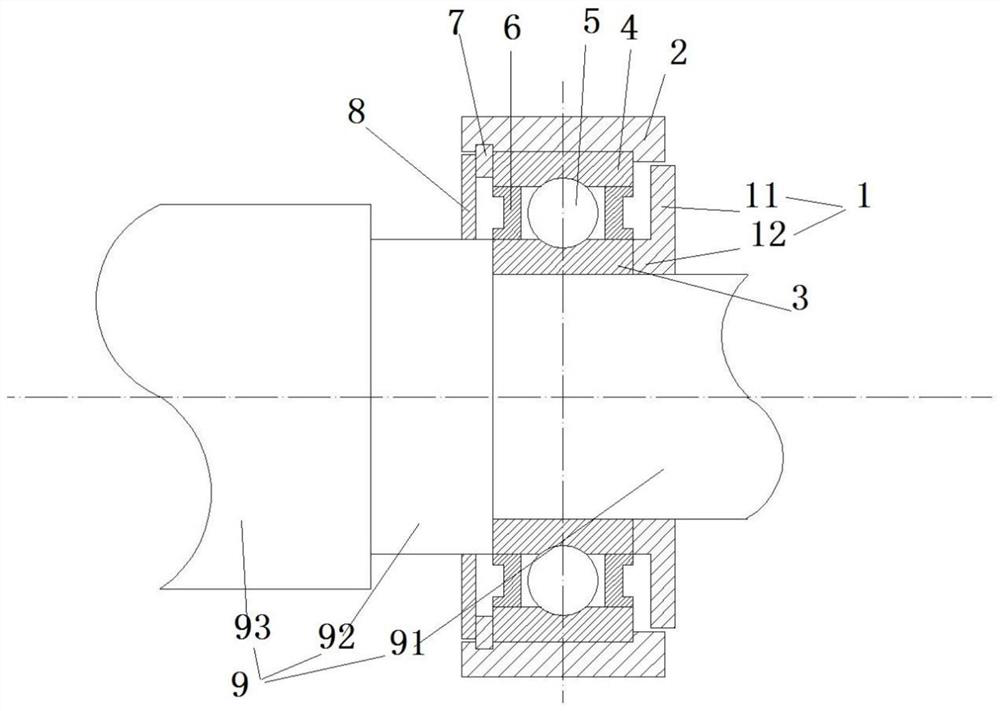

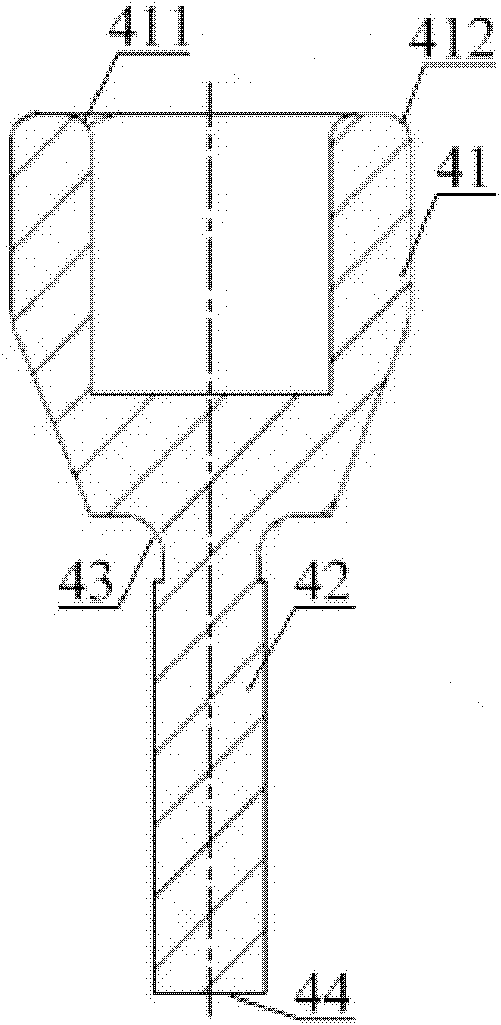

Deep groove ball bearing with a rotor

ActiveUS20180298950A1Small sizeImprove sealingConnecting rod bearingsEngine sealsBall bearingSteel ball

A deep groove ball bearing with a rotor is disclosed by the present invention. The deep groove ball bearing with a rotor comprises a mandrel, at least one bearing assembly structure mounted on the periphery of the mandrel, and a magnet structure; wherein the bearing assembly structure, along with the mandrel to constitute the deep groove ball bearing structure, includes an outer ring sleeved on the periphery of the mandrel, steel balls, and an inner sealing cover; wherein the periphery of the mandrel is provided with at least one lap of channel that matches with a groove provided on the inner surface of the outer ring, and the steel balls are installed between the channel and the groove; wherein the periphery of the out ring is axially embedded with an inner sealing cover for sealing the inner side of the outer ring; wherein the magnet structure includes a permanent magnet glued on the periphery of the mandrel, a reinforcing sleeve sleeved outside the permanent magnet, and a balance ring provided at one end of the permanent magnet. The technical solution enables the bearing to run smoothly under high revolution speed conditions, and has a small size, good sealing performance and long service life. O-rings are installed on the outer ring to facilitate the damping and assemble and disassemble.

Owner:NINGBO ZHENHAI SILVER BALL BEARING CO LTD

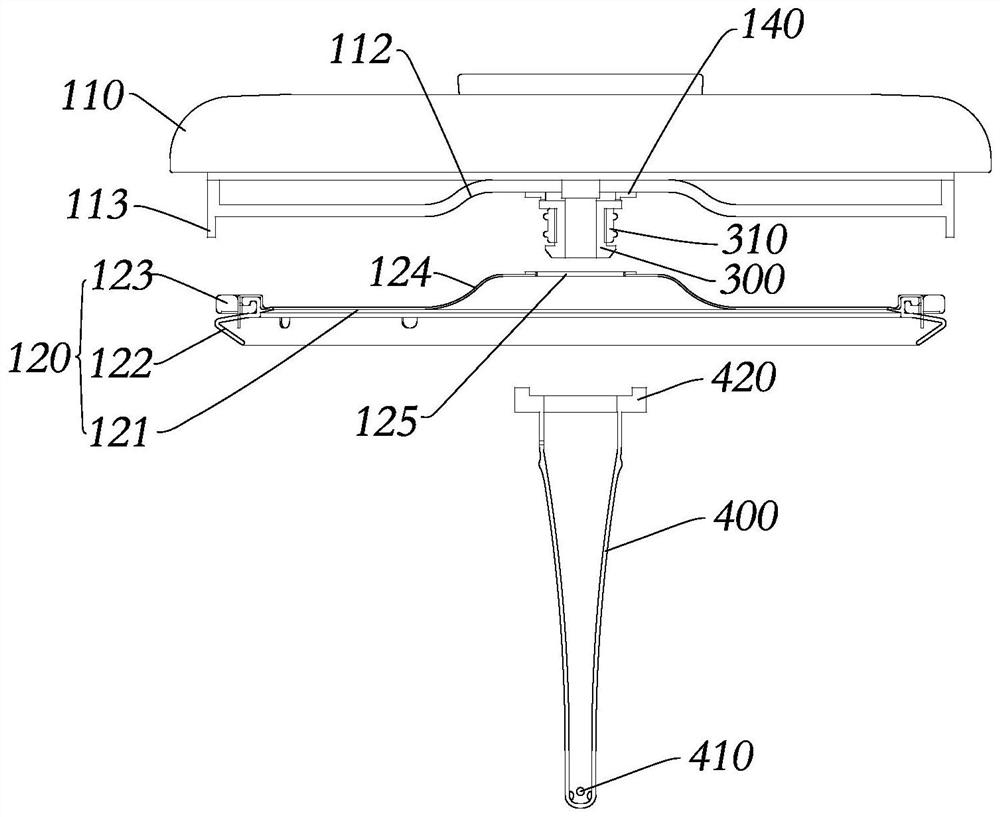

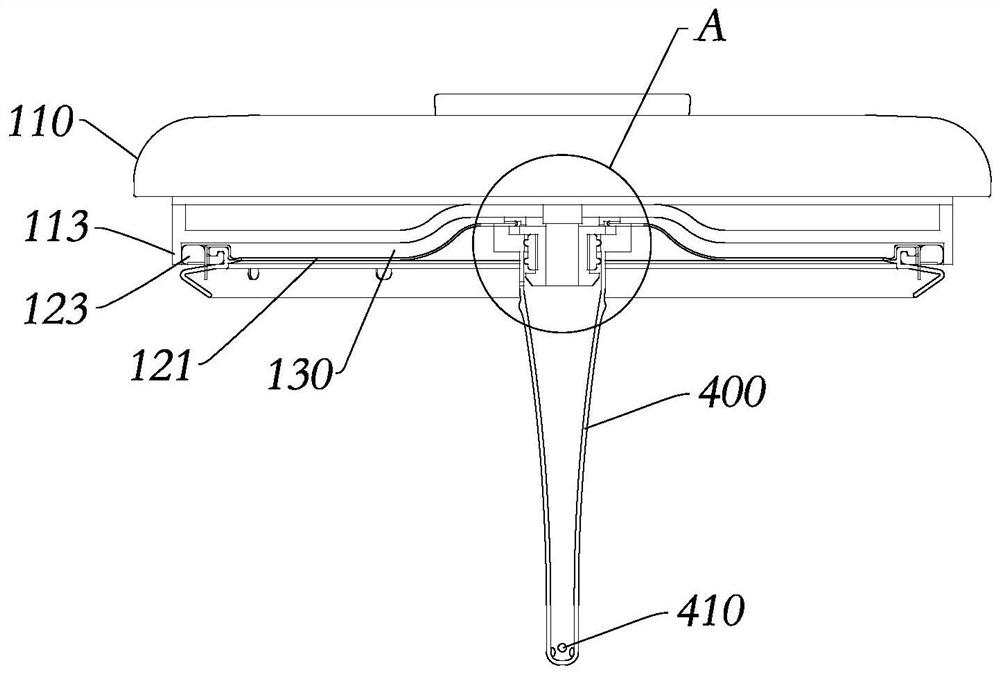

Cable pay-off vehicle

ActiveCN102655316BConvenient parkingFirmly connectedArrangements using take-up reel/drumTurning framesEngineering

The invention relates to the field of cable taking-up and paying-off equipment, and aims to provide a cable wire barrow of which a transmission mechanism between a power machine and a take-up drum has functions of overload protection and labor conservation by manually rotating the take-up drum. The cable wire barrow comprises a car frame with wheels, a bearing frame, a rotating shaft, a driving device which is used for driving the rotating shaft, a transmission device, a wire plate shaft, a traction rope plate, a transmission fork and an opening and closing retainer, wherein the wire plate shaft comprises a connecting section, a cable section, a bearing section and a traction section which are connected with one another in sequence; the rotating shaft comprises a transmission section and a supporting section; the transmission section of the rotating shaft is pivoted with the bearing frame, and the transmission fork is sleeved outside the supporting section and is fixedly connected with the supporting section; and the connecting section is detachably and fixedly connected with the supporting section, the opening and closing retainer bears the bearing section, and the traction rope plate is sleeved outside the traction section. The cable wire barrow ensures that the paying off of cables is easy and labor-saving when the cables are relatively thick and heavy and a paying-off path is bumpy.

Owner:HANGZHOU ELECTRIC EQUIP MFG +3

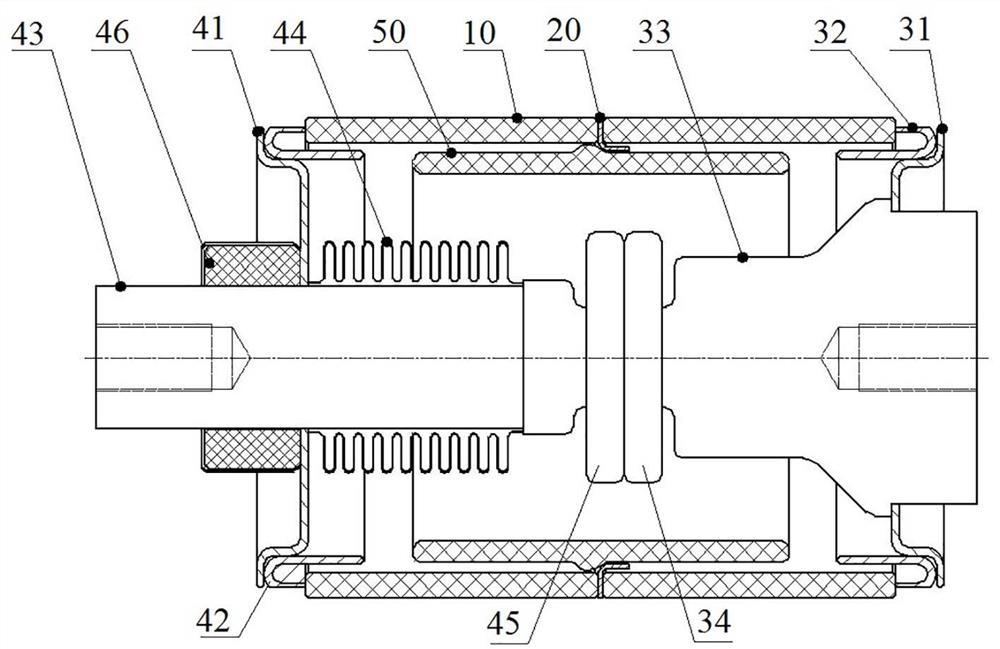

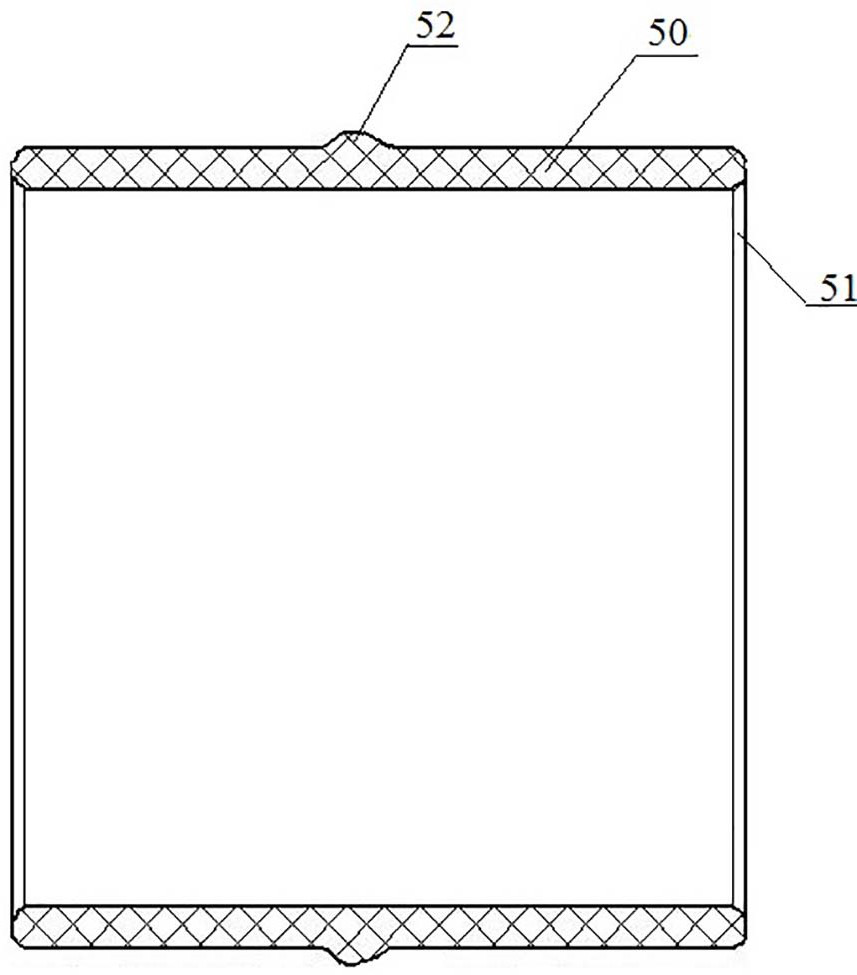

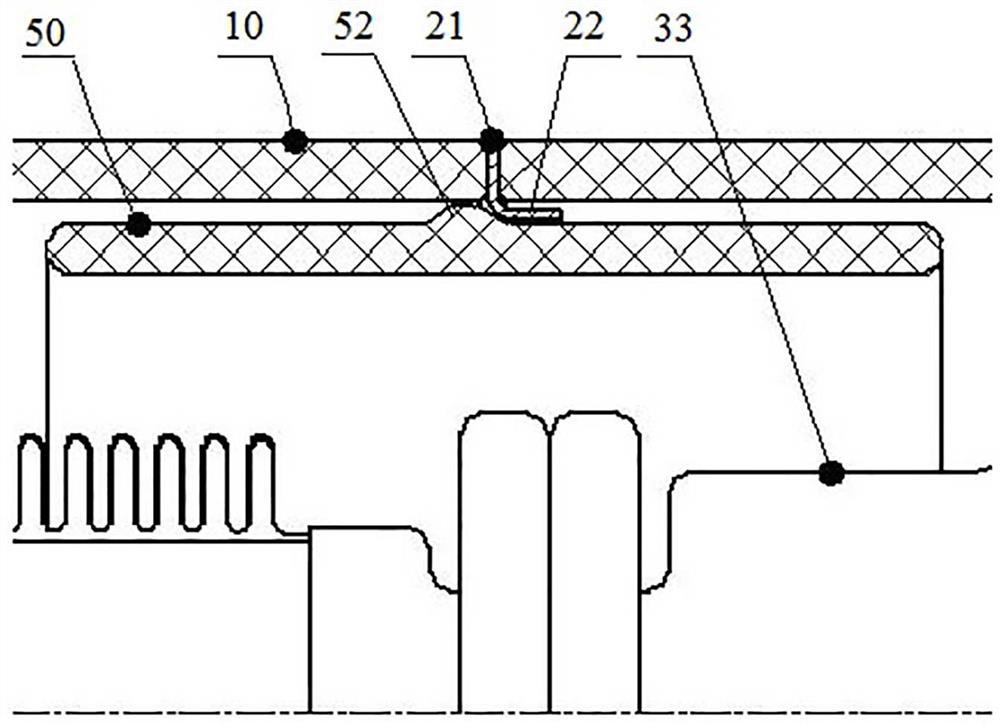

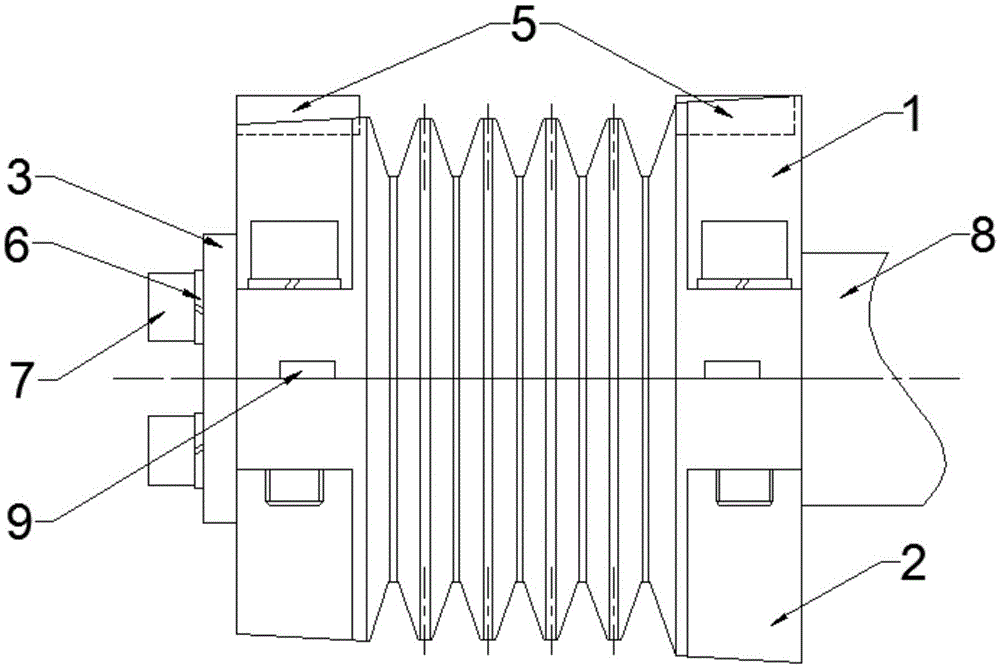

Main shielding case of vacuum arc-extinguishing chamber and vacuum arc-extinguishing chamber

PendingCN112614733AEasy to fixAvoid it happening againHigh-tension/heavy-dress switchesAir-break switchesEngineeringMechanical engineering

The invention relates to a main shielding case of a vacuum arc-extinguishing chamber and the vacuum arc-extinguishing chamber. The vacuum arc-extinguishing chamber comprises two sections of shells, a main shielding case and a metal middle sealing ring, wherein the two sections of shells are in butt joint in the axial direction of the vacuum arc-extinguishing chamber; the main shielding case is used for surrounding the outer side of the joint of the moving contact and the static contact; the metal middle sealing ring is welded and fixed between the two sections of shells and is used for welding and fixing the main shielding case; the main shielding case is made of a ceramic material; a metallization layer is arranged on the outer peripheral surface of the main shielding case; and the metallization layer is arranged around the outer peripheral surface of the main shielding case to form a middle sealing ring connecting part which is used for being welded and fixed with a metal middle sealing ring between two sections of shells of the vacuum arc-extinguishing chamber so as to realize the fixation of the main shielding case. According to the scheme, the problem that the insulation performance of the vacuum arc-extinguishing chamber in the prior art is greatly influenced by metal vapor and miniaturization is not facilitated can be solved.

Owner:TIANJIN PINGGAO INTELLIGENT ELECTRIC +2

Deep groove ball bearing with a rotor

ActiveUS10197101B2Small sizeImprove sealingConnecting rod bearingsEngine sealsBall bearingSteel ball

Owner:NINGBO ZHENHAI SILVER BALL BEARING CO LTD

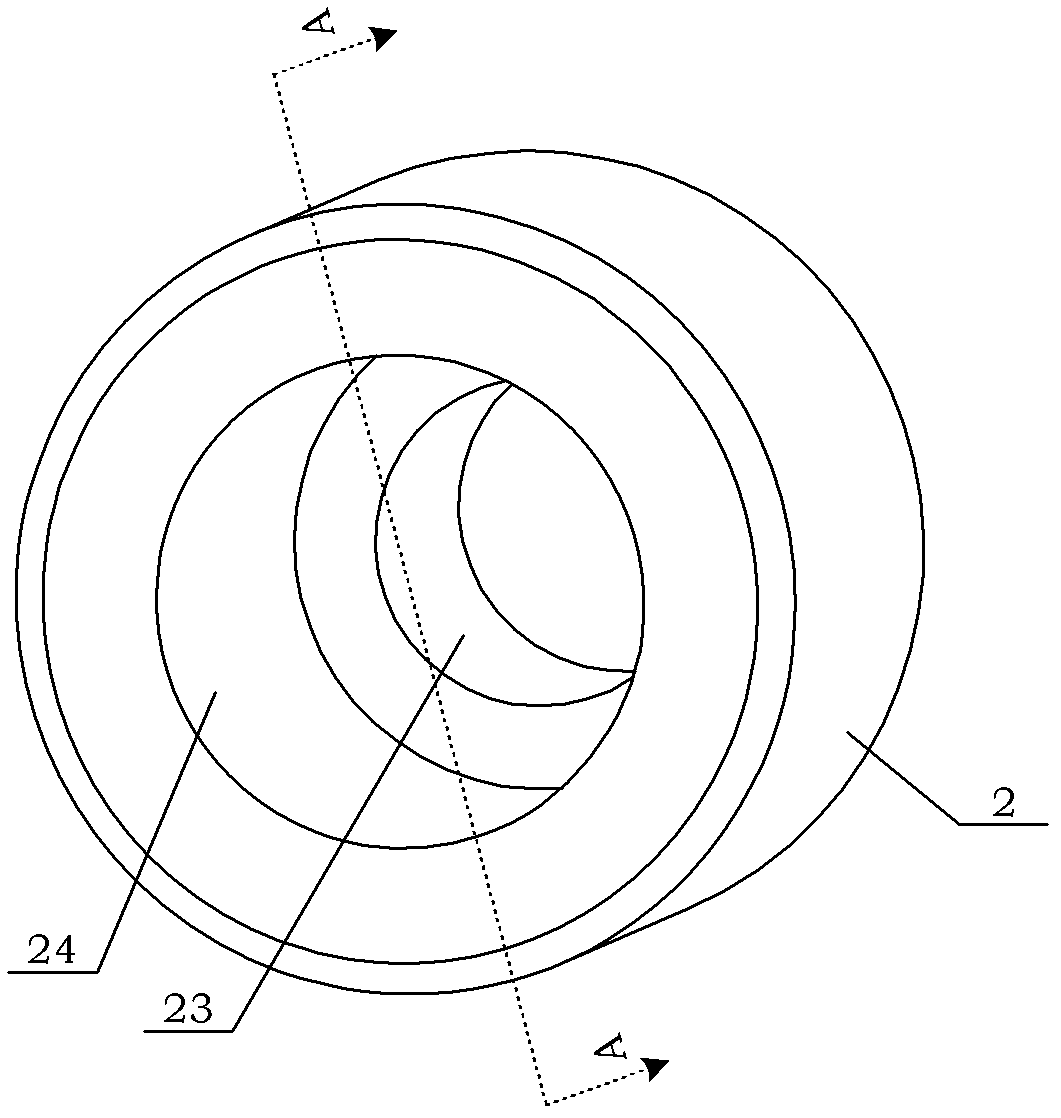

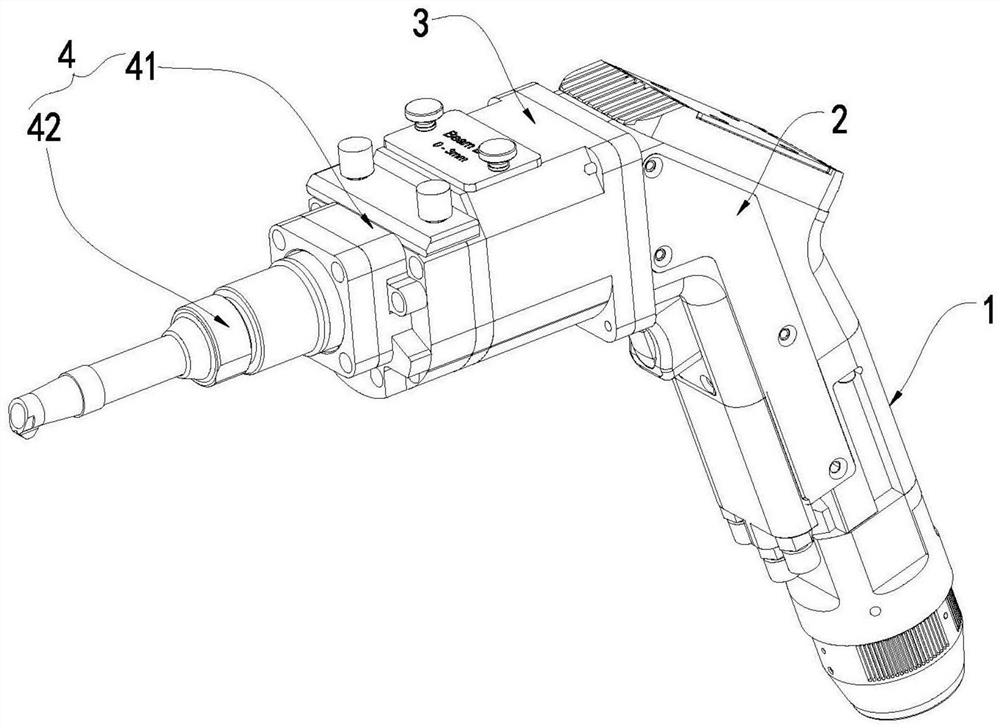

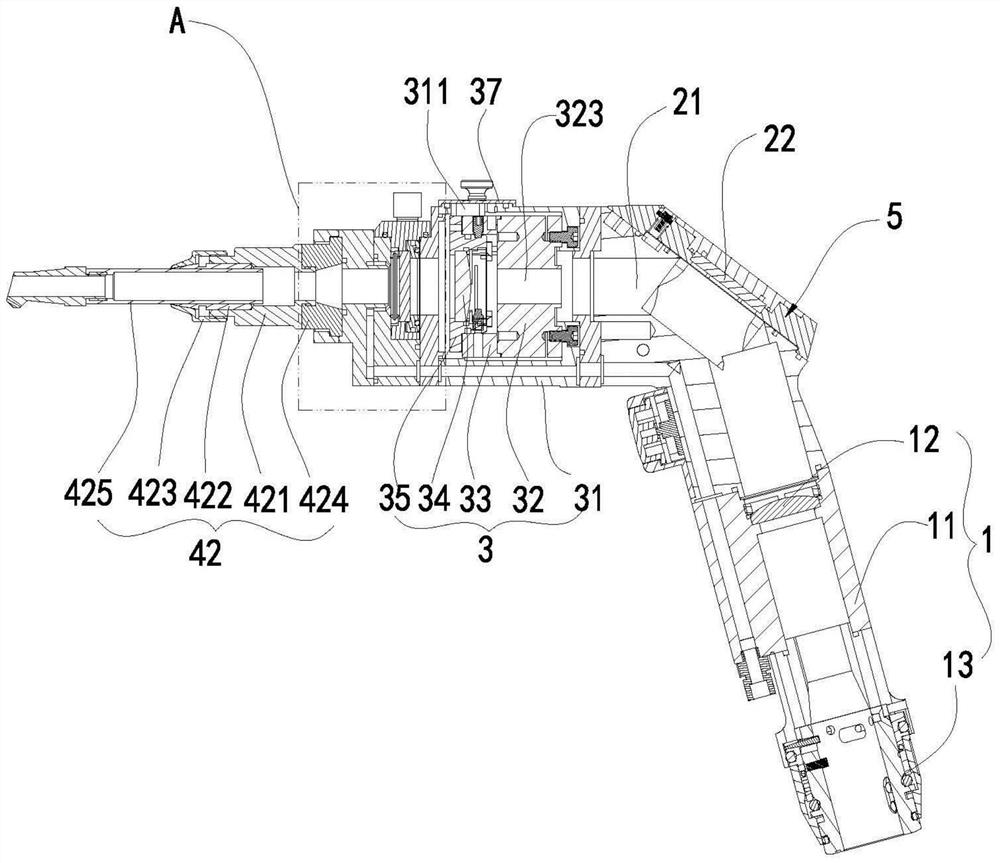

Hand-held laser welding head with adjustable light spots

PendingCN114160963ARelative position adjustableSpot Size AdjustmentLaser beam welding apparatusLight spotElectric machinery

The handheld laser welding head comprises a collimation assembly, a reflection assembly, an adjusting assembly and an emitting assembly which are connected in sequence, the adjusting assembly comprises a shell, a holder motor, an adapter disc, a mirror box and a focusing mirror, the holder motor, the adapter disc, the mirror box and the focusing mirror are arranged in the shell, a light through hole is formed in the center of the holder motor, and the holder motor comprises a stator and a rotor; one end of the switching disc is coaxially and fixedly connected with the rotor, a through hole is eccentrically formed in the switching disc, the distance from the center axis of the through hole to the center axis of the light through hole is a first preset value, the lens box is rotationally arranged at the other end of the switching disc, a through groove is eccentrically formed in the lens box, and the focus lens is coaxially and fixedly arranged in the through groove. The distance between the center axis of the through groove and the center axis of the through hole is a second preset value, the second preset value is smaller than or equal to the first preset value, and the mirror box is rotated around the center of the through hole in the transfer disc by rotating the mirror box, so that the relative position of the focus lens is adjustable, the emergent laser rotates with the center of the rotor as the center axis, and an adjustable circular light spot is formed.

Owner:武汉奥森迪科智能科技股份有限公司

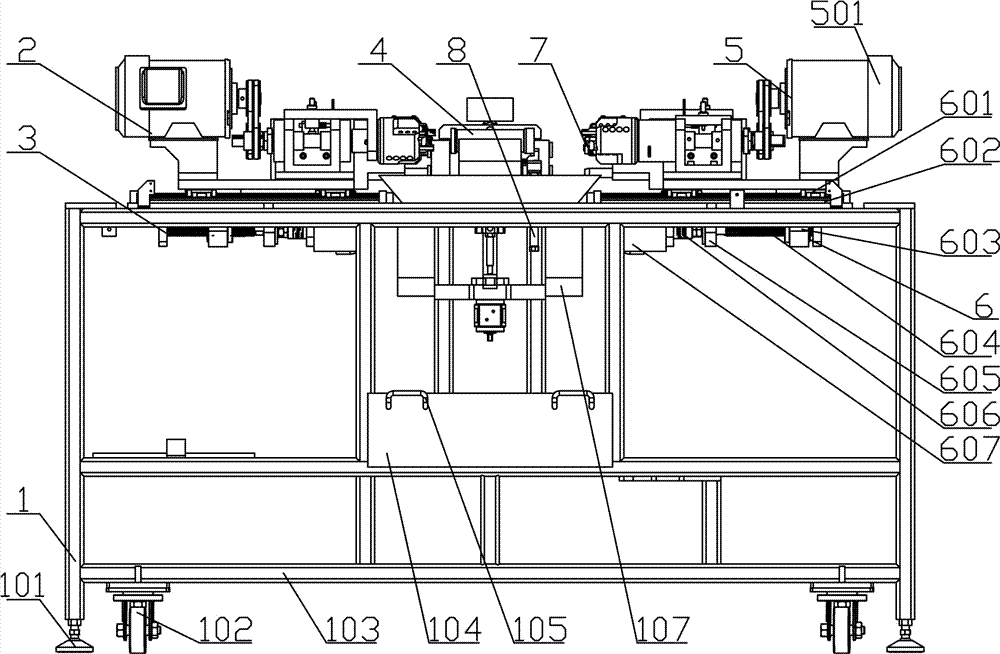

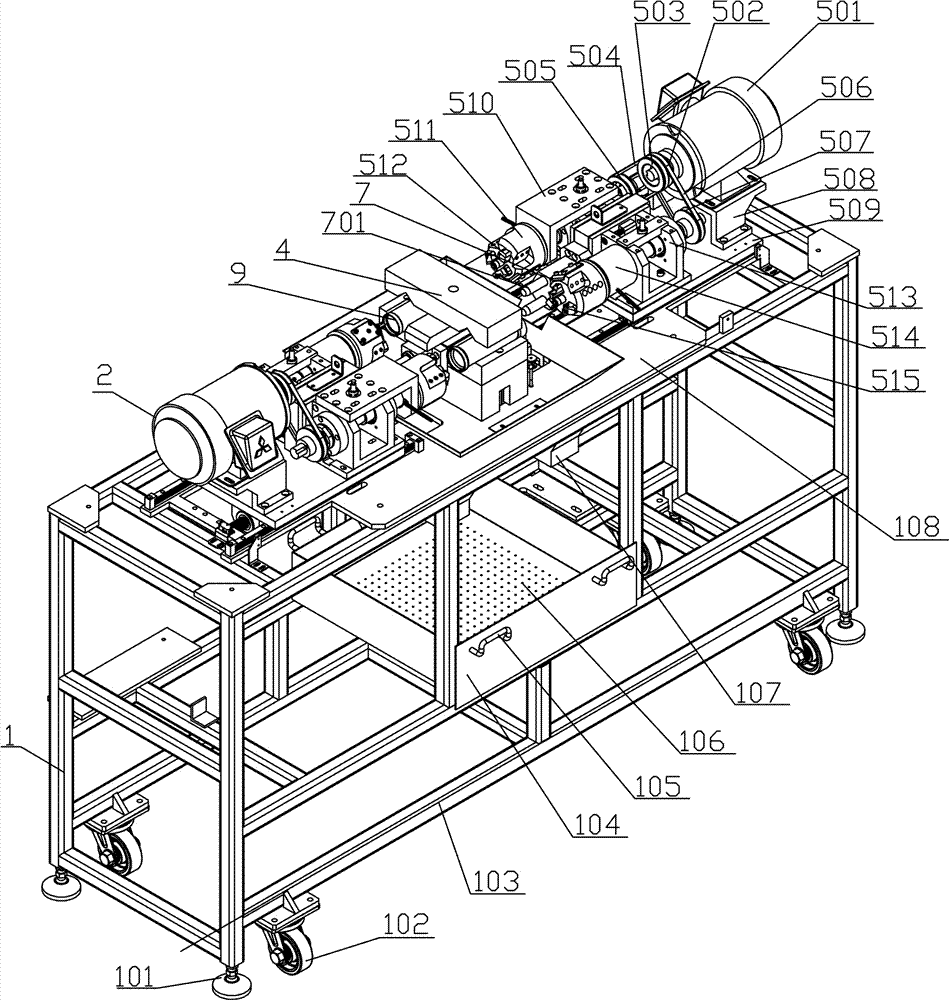

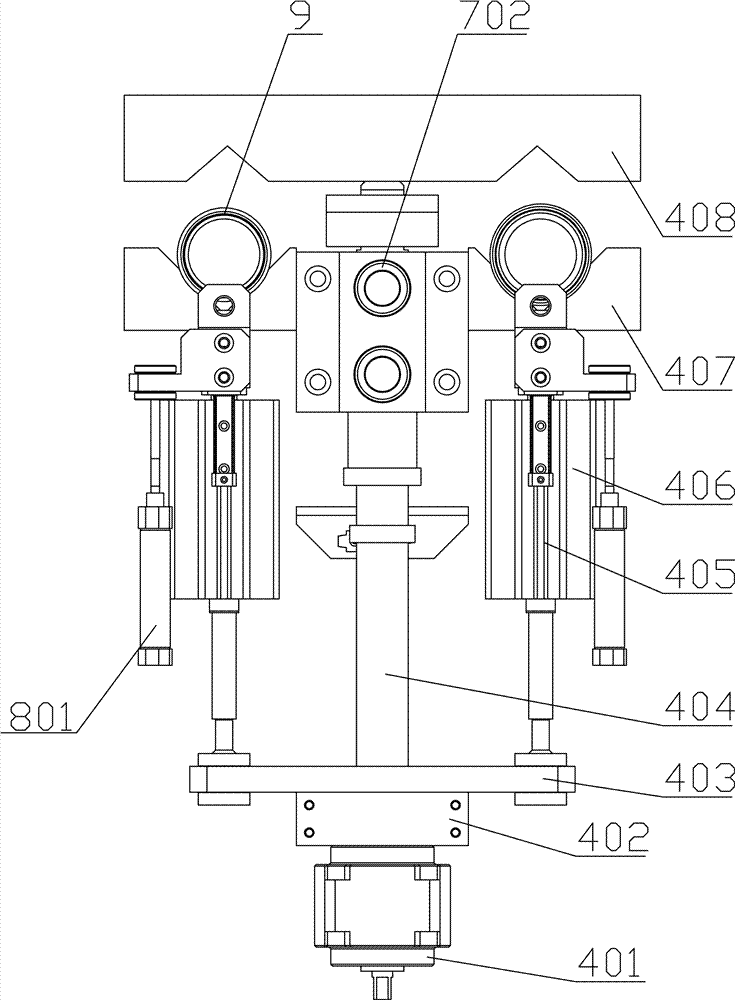

A bushing automatic boring equipment and processing method

The invention discloses automatic boring equipment for a bush and a machining method. The automatic boring equipment comprises a supporting structure. A workbench is mounted at the top of the supporting structure. A left main cutting device is fixedly mounted at the upper top of the left side of the workbench and mounted on a left feed device. The left feed device is mounted on the lower bottom face of the left side of the workbench. A right main cutting device is fixedly mounted at the upper top of the right side of the workbench and mounted on a right feed device. The right feed device is mounted on the lower bottom face of the right side of the workbench. A clamping device is arranged between the left main cutting device and the right main cutting device. A workpiece locating mechanism is arranged at the lower bottom of the clamping device. A tool locating mechanism is arranged among the clamping device, the left main cutting device and the right main cutting device. By means of the equipment, the two ends of a hole can be machined at the same time, and the equipment can be adjusted according to the size of the bush so that the equipment can adapt to machining of bushes of different specifications.

Owner:平邑仁安中医药产业发展有限公司

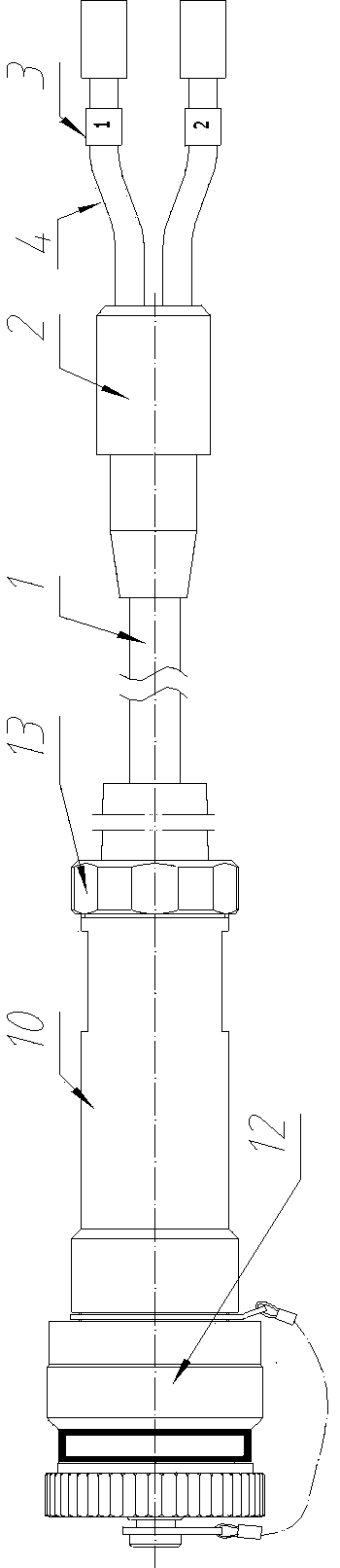

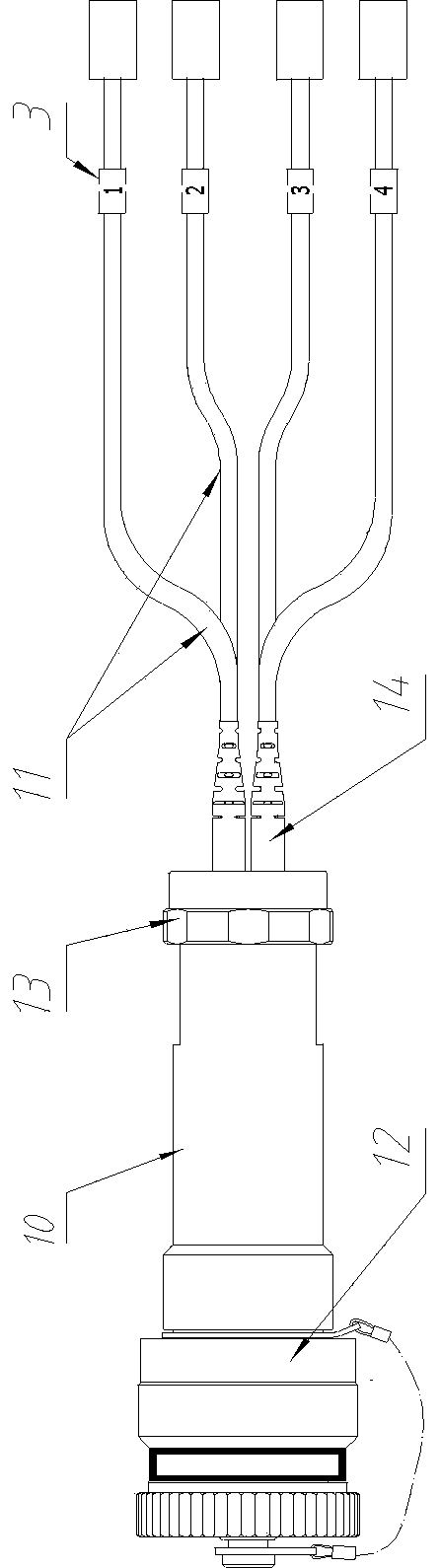

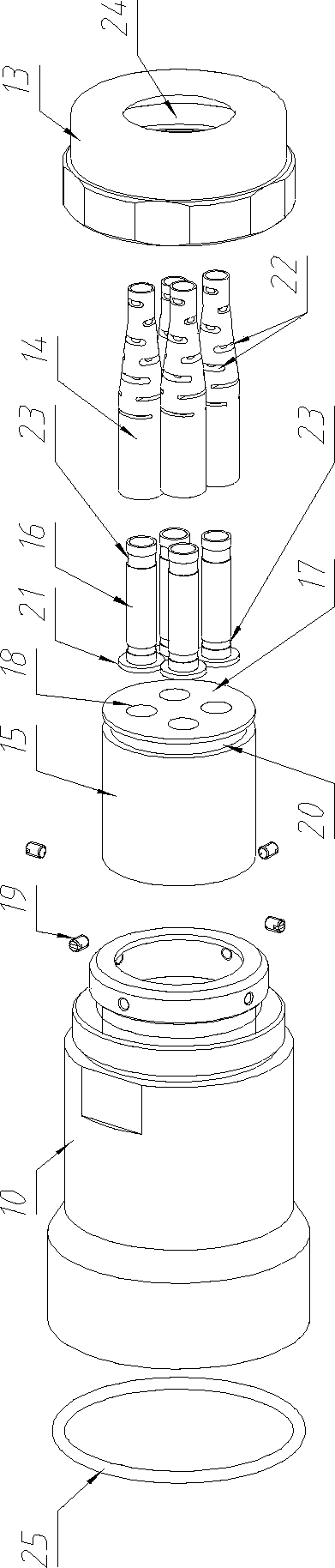

Tail accessory for optical fiber connector, optical fiber connector and optical cable assembly

ActiveCN110187443AAvoid excessive bendingPrevent twistingCoupling light guidesEngineeringOptical fiber connector

The invention relates to an optical fiber connector, especially relates to a tail accessory for the optical fiber connector, and provides the tail accessory for the optical fiber connector, the optical fiber connector and an optical cable assembly. Wherein the tail accessory includes a sleeve, the rear part of the sleeve is provided with an adhesive sleeve for lead-out optical cables to pass through and to bond and fix, the rear end of the adhesive sleeve is provided with a plugging body, the plugging body is provided with two or more optical cable pass-through holes used for optical cables topass through, the tail end of the tail accessory is fixedly provided with anti-bending sleeves for each of the optical cables to pass through, and the anti-bending sleeves are used for avoiding overbending of the optical cables. The scheme can achieve simultaneous piercing of more than two optical cables, so that optical cables with thin diameter can be utilized, the minimum bending radius can bereduced, occupation of a bending space can be saved, a deconcentrator can be omitted, and the cost can be reduced. At the same time, since more than two optical cables are simultaneously disposed onthe adhesive sleeve, rotation of a single optical cable does not form rotational moment on the entire adhesive sleeve, and an optical fiber inside a sleeve pipe is prevented from being twisted.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Belt wheel transmission component

The invention discloses a belt wheel transmission component. The belt wheel transmission component comprises a transmission shaft, a belt wheel and a fixing seat. A mounting hole is formed in the fixing seat in a penetrating manner. The transmission shaft is supported inside the mounting hole. One end of the transmission shaft is provided with the belt wheel. The two ends of the fixing seat are provided with bearing end covers. The bearing end covers are arranged on the transmission shaft in a sleeving manner. A seal assembly is arranged at the outer end of each bearing end cover in a sealed manner. Each seal assembly comprises an outer cover, a seal disc and a seal ring. The outer end of each bearing end cover is provided with a step-shaped groove in the axial direction. Each step-shapedgroove is composed of a small hole diameter groove, a connecting groove and a large hole diameter groove from inside to outside in a communicating manner. The diameter of each small hole diameter groove is less than that of the corresponding connecting groove. The diameter of each connecting groove is less than that of the corresponding large hole diameter groove. Each seal ring is mounted in thecorresponding small hole diameter groove in a clamped and inlaid manner. Each seal disc is arranged in a cavity form by the corresponding connecting groove and the corresponding large hole diameter groove in a clamped and inlaid manner. Each outer cover is detachably connected with the corresponding bearing end cover and tightly presses the outer end of the corresponding seal disc. The belt wheeltransmission component is simple in design, good in locating effect and convenient to mount and adjust.

Owner:徐菊梅

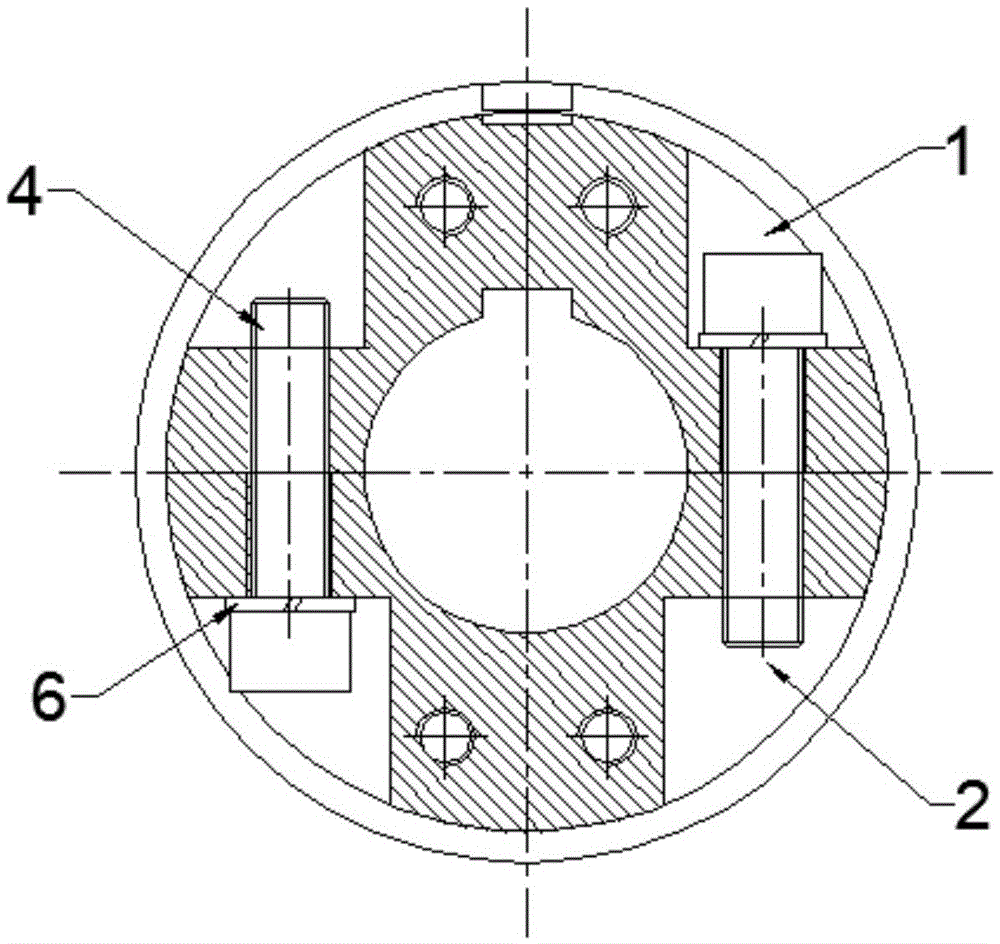

A shaft and bearing matching structure

ActiveCN109915471BReduced risk of cracks or even breakageImprove efficiencyShaftsGearing detailsInterference fitStress concentration

The invention discloses a shaft and bearing matching structure for axially positioning a bearing on a shaft or a rod without a groove. The shaft and bearing matching structure comprises a long-handlethree-column-groove shell rod part, a bearing support, the bearing and a pressing ring, wherein the bearing is fixed on the bearing support; the bearing comprises a bearing inner ring, a bearing outerring, a plurality of rollers and a bearing sealing ring, the bearing is arranged on the long-handle three-column-groove shell rod part in a sleeve mode, the pressing ring is arranged on the long-handle three-column-groove shell rod part in a sleeve mode, and the pressing ring is fixed on one side of the bearing; and the inner side wall of the pressing ring is in interference fit with the long-handle three-column-groove shell rod part, and the pressing ring carries out axial positioning on one side of the bearing. Due to the fact that the long-handle three-column-groove shell rod part is freeof the groove, the problem of concentrated stress is avoided, and the risk of generating cracks during torsional fatigue is reduced; and compared with an axial positioning structure adding an limitingbaffle ring to the groove, the axial positioning effect of the shaft and bearing matching structure is better.

Owner:WANXIANGQIANCHAO CO LTD +1

In-situ test positioning controllable mechanical loading and fixing device

InactiveCN102506791BFacilitates axial positioningMove quicklyMeasurement devicesEngineeringRepeatability

Owner:BEIHANG UNIV

Concrete pump with lift type hopper fence

InactiveCN106567388AAvoid wear and tearWear will notUnderground chambersFoundation engineeringArchitectural engineeringConcrete pump

The invention discloses a concrete pump with a lift type hopper fence for thoroughly solving the concrete accumulation problem. The concrete pump comprises a concrete stirring device, a hopper, a fence and a frame; a mounting frame is fixed on one side of the frame; a lift driving device is fixed on the mounting frame; a mounting plate is fixed at the lower end of a lifting rod of the lift driving device; a vibration device is fixed on the mounting plate; the vibration device includes a pneumatic vibrator and a vibrator clamping device; multiple guide rod passing holes are formed in the vibrator clamping device; clamping device guide rods are slidingly matched in the guide rod passing holes; the upper and lower extension ends of the clamping device guide rods are respectively coated with compression springs; and the lower ends of the clamping device guide rods are fixedly connected with the mounting plate.

Owner:重庆华耀混凝土有限公司

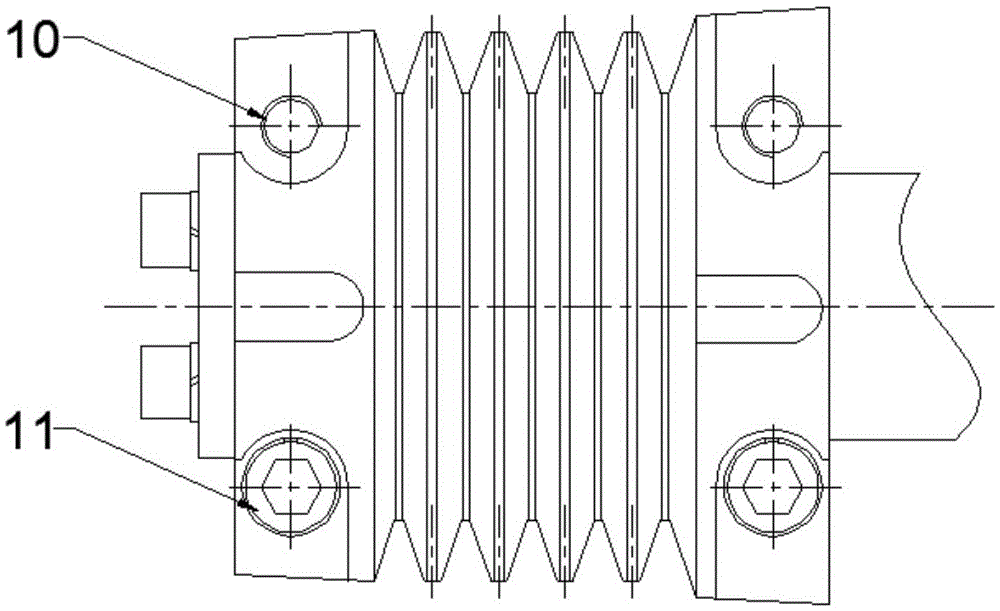

Paint pneumatic vibration filtering device

The invention discloses a paint pneumatic vibration filtering device which has a simple structure and is externally provided with a vibration mechanism. The paint pneumatic vibration filtering device comprises a connecting pipe, wherein a filtering barrel is erected in the connecting pipe, a threaded connecting hole is radially formed in the outer peripheral surface of the filtering barrel, an allowance strip-shaped hole is axially formed in the wall of the connecting pipe and corresponds to the threaded connecting hole, a corrugated pipe is sheathed on the wall of the connecting pipe and can completely cover the allowance strip-shaped hole in the wall of the connecting pipe, the upper end and lower end of the corrugated pipe are adhered and fixed on the wall of the connecting pipe to form sealing, a threaded connecting head is fixedly arranged on the body of the corrugated pipe and corresponds to the allowance strip-shaped hole and the threaded connecting hole, the threaded connecting head is in threaded matching with a screw, one end of the screw penetrates through the allowance strip-shaped hole and is in threaded matching with the threaded connecting hole in the filtering barrel, a connecting head is arranged on the other end of the screw and is connected with the pneumatic vibration device fixedly arranged on the wall of the connecting pipe, and the pneumatic vibration device is used for driving the filtering barrel to vibrate up and down through the screw.

Owner:CHONGQING QICAIHONG CHEM

Cooking pots and steam-heating cooking appliances for steam heating

ActiveCN110338641BExtend your lifeReduce entryBoiling over preventionCooking-vessel lids/coversThermodynamicsMechanical engineering

Owner:JOYOUNG CO LTD

Split combined belt pulley

The invention provides a split combined belt pulley. The split combined belt pulley comprises two half pulley bodies. Axial positioning keys are arranged on one of the half pulley bodies. The axial positions of the two half pulley bodies are positioned through the axial positioning keys, and the two half pulley bodies are buckled into a whole. The two half pulley bodies are detachably connected. A sleeve wheel is arranged outside the whole in a sleeving mode. A half pulley body pressing cover is detachably connected with the end face of the tail end of an installed power shaft. A sleeve wheel pressing cover is detachably connected with the end faces of the tail ends of the two half pulley bodies. The split combined belt pulley has the beneficial effects that a traditional belt pulley is split into two parts, namely the two half pulley bodies, so that the tedious steps during maintenance of the belt pulley are greatly simplified and the replacing difficulty is lowered; the good position function is provided for installation of the two half pulley bodies by arranging the axial positioning keys, so that the two half pulley bodies are buckled more conveniently and accurately; the good axial positioning function is provided for the two half pulley bodies and a transmission device assembled with the two half pulley bodies by arranging the half pulley body pressing cover; the sleeve wheel is in key transmission with the half pulley bodies and positioned through a conical face, so that disassembling, assembling and positioning are convenient.

Owner:天津市瑞资科技有限公司

Radial guide

PendingCN111853056AFacilitates axial positioningOperating means/releasing devices for valvesSliding contact bearingsEngineeringMechanical engineering

Owner:MINEBEA CO LTD

Laughing gas inlet valve

InactiveCN103182130APrevent excessive deformationAffect uneven openingRespiratorsInlet valveEngineering

The invention discloses a laughing gas inlet valve which comprises a valve body and a valve core, wherein the valve core is arranged in the valve body; the valve core comprises a valve head and a valve rod; a plurality of semi-round gas holes are uniformly formed in the outer circle of the valve head; the valve head is provided with a groove used for mounting a spring; the end surface at the top of the groove is the upper end surface of the valve core; the upper end surface of the valve core is provided with an inner edge line with an arc chamfer and an outer edge line with an arc chamfer; and an arc-shaped seal ring boss is arranged at the joint of the valve head and the valve rod. The cross section structure of the valve core is changed into a semi-round structure, so that the ventilation effect can be achieved, the convenience is provided for the mechanical processing operation, and the axial positioning effect is good; the inner edge line of the upper end surface of the valve core is rounded, so that the upper end surface of the valve core can be prevented from colliding with the spring; the outer edge line of the upper end surface of the valve core is rounded, so that the frictional force in the position where the outer edge line is contacted with the inner wall of the valve body can be reduced; and the position where the valve core is contacted with a seal ring is set to be arc-shaped, so that the phenomenon of excessive deformation due to long-term use of the seal ring can be avoided.

Owner:BEIJING AEONMED

Shaft and bearing matching structure

ActiveCN109915471AImprove efficiencyReduce processShaftsGearing detailsStress concentrationInterference fit

The invention discloses a shaft and bearing matching structure for axially positioning a bearing on a shaft or a rod without a groove. The shaft and bearing matching structure comprises a long-handlethree-column-groove shell rod part, a bearing support, the bearing and a pressing ring, wherein the bearing is fixed on the bearing support; the bearing comprises a bearing inner ring, a bearing outerring, a plurality of rollers and a bearing sealing ring, the bearing is arranged on the long-handle three-column-groove shell rod part in a sleeve mode, the pressing ring is arranged on the long-handle three-column-groove shell rod part in a sleeve mode, and the pressing ring is fixed on one side of the bearing; and the inner side wall of the pressing ring is in interference fit with the long-handle three-column-groove shell rod part, and the pressing ring carries out axial positioning on one side of the bearing. Due to the fact that the long-handle three-column-groove shell rod part is freeof the groove, the problem of concentrated stress is avoided, and the risk of generating cracks during torsional fatigue is reduced; and compared with an axial positioning structure adding an limitingbaffle ring to the groove, the axial positioning effect of the shaft and bearing matching structure is better.

Owner:WANXIANGQIANCHAO CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com