A bushing automatic boring equipment and processing method

A technology of bushing and boring, which is applied in the direction of drilling/drilling equipment, boring/drilling, metal processing equipment, etc. The problem of low degree of automation can achieve the effect of shortening the processing time, ensuring the safety of processing, and facilitating the feed rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

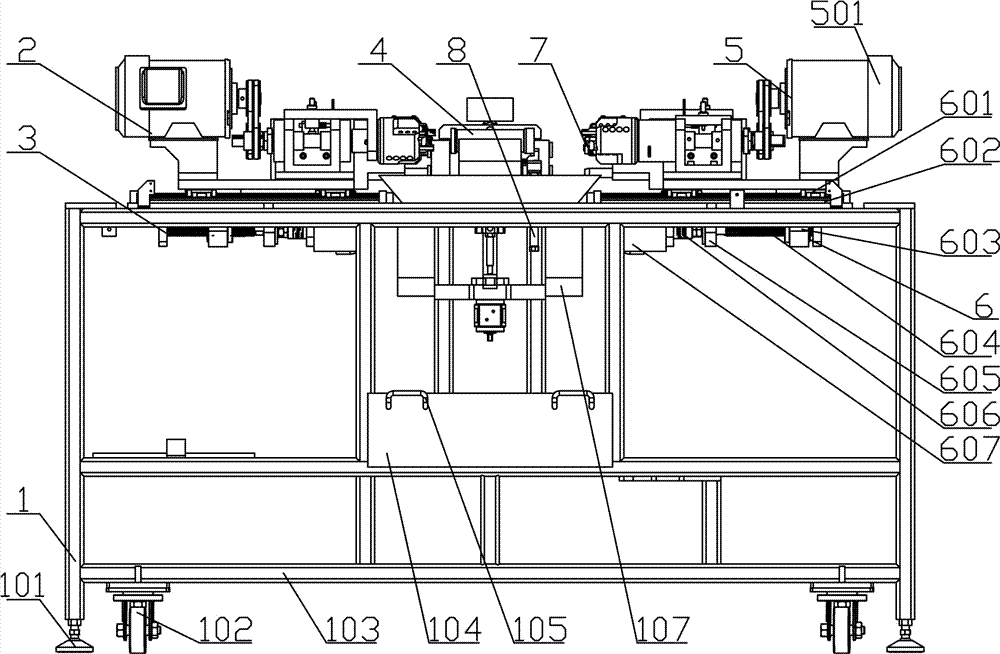

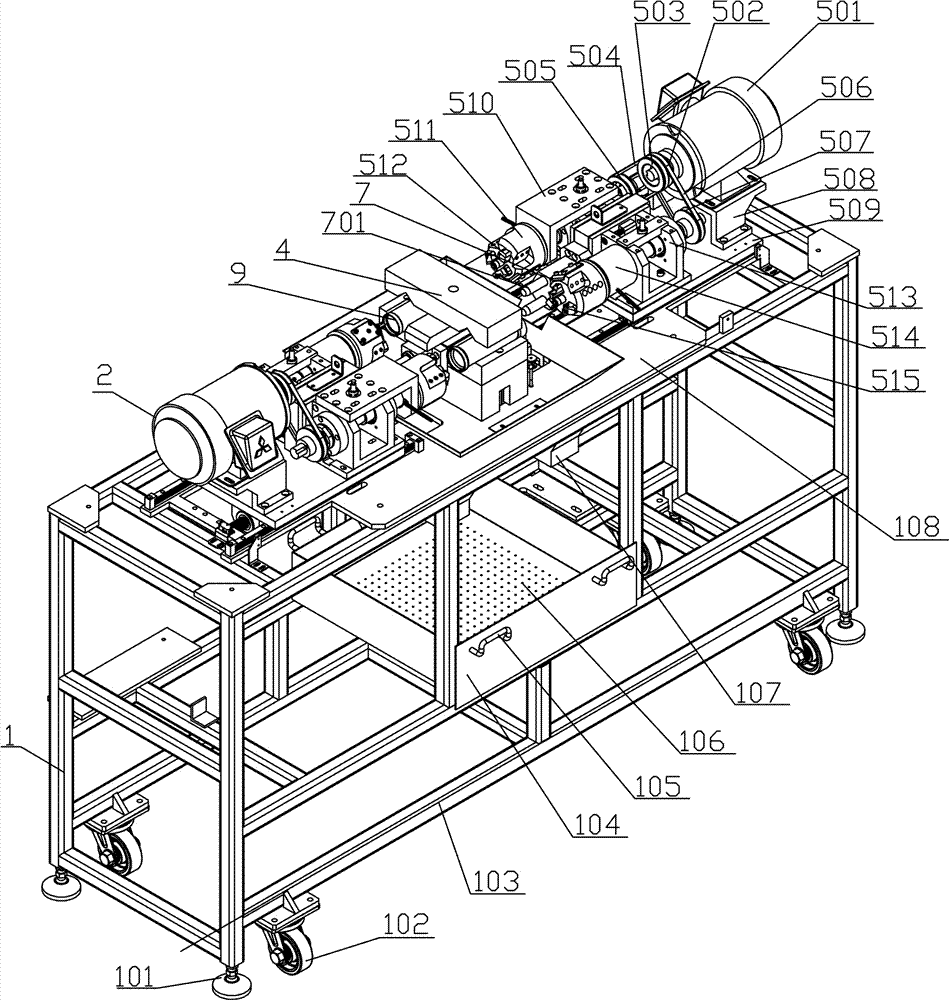

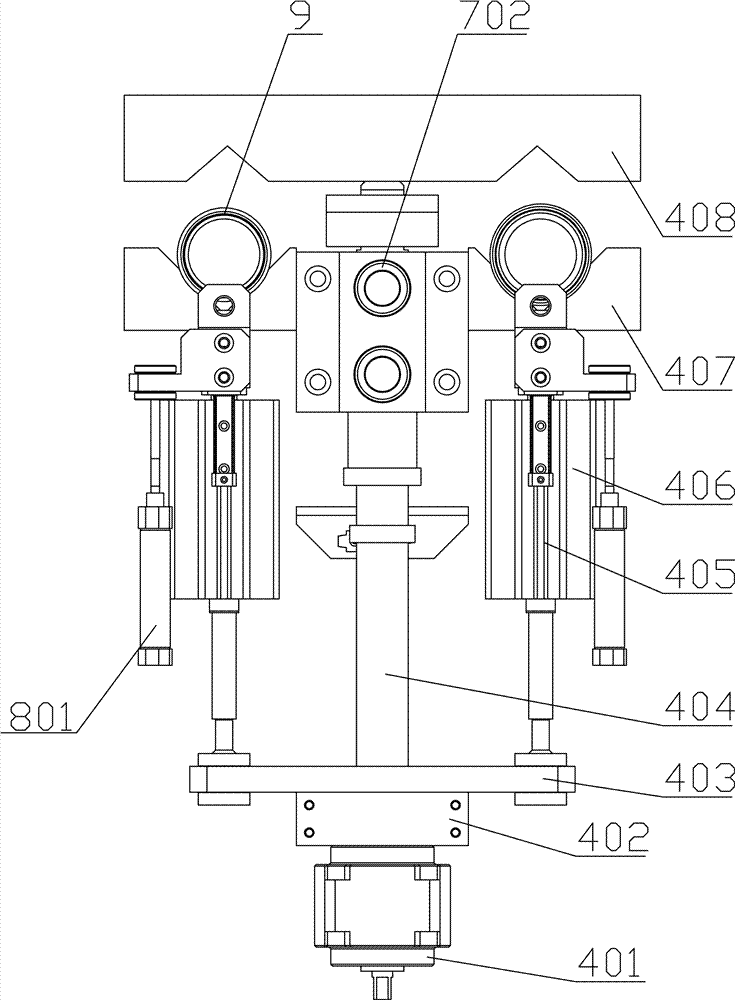

[0044] Such as Figure 1-5 As shown, a bushing automatic boring equipment, which includes a support structure 1, a workbench 108 is installed on the top of the support structure 1, and a left main cutting device 2 is fixedly installed on the upper left side of the workbench 108. The left main cutting device 2 is installed on the left feed device 3, and the left feed device 3 is installed on the left lower bottom surface of the workbench 108; Cutting device 5, the main cutting device 5 on the right side is installed on the feeding device 6 on the right side, and the feeding device 6 on the right side is installed on the lower bottom surface of the right side of the workbench 108; the main cutting device 2 and the main cutting device on the left side A clamping device 4 is arranged between the main cutting devices 5 on the right side, and a workpiece positioning mechanism 8 is arranged on the lower bottom of the clamping device 4, and the clamping device 4 is connected with the ...

Embodiment 2

[0058] A method for processing a bush with automatic boring equipment for a bush, comprising the following steps:

[0059] 1. Tool setting operation, according to the processing requirements of the bush to be processed, select the appropriate left tool 512 and right tool 515, and install the left tool 512 and right tool 515 on the left spindle 511 and right spindle 514 respectively, and install them at the same time The tool on the left main cutting device 2 pushes the left main cutting device 2 and the right main cutting device 5 to move on the corresponding slide rails respectively, and adjusts the height position of the workpiece supporting seat 407 so that the guide pin shaft 701 is aligned with the positioning pin. The matching positioning of the sleeve 702 realizes the tool setting operation of the tool.

[0060] 2. Clamp the workpiece, drive the limit cylinder 801, lift the limit block 805, put the workpiece 9 into the wedge-shaped hole between the workpiece support sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com