Stroke control mechanism of metering pump

A stroke adjustment and metering pump technology, which is applied in pumps, pump control, mechanical equipment, etc., can solve problems such as low reliability, wear, and difficult parts processing, and achieves easy wear, simple processing technology, and good axial positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

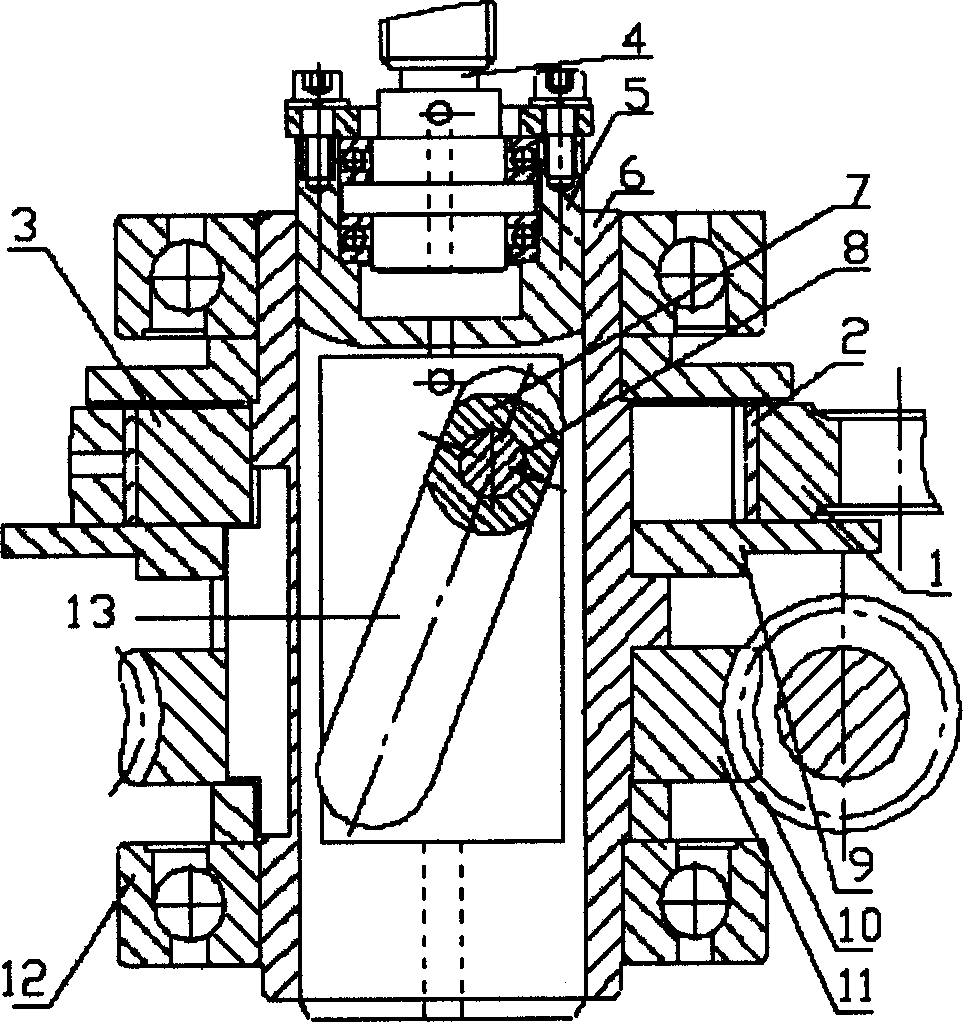

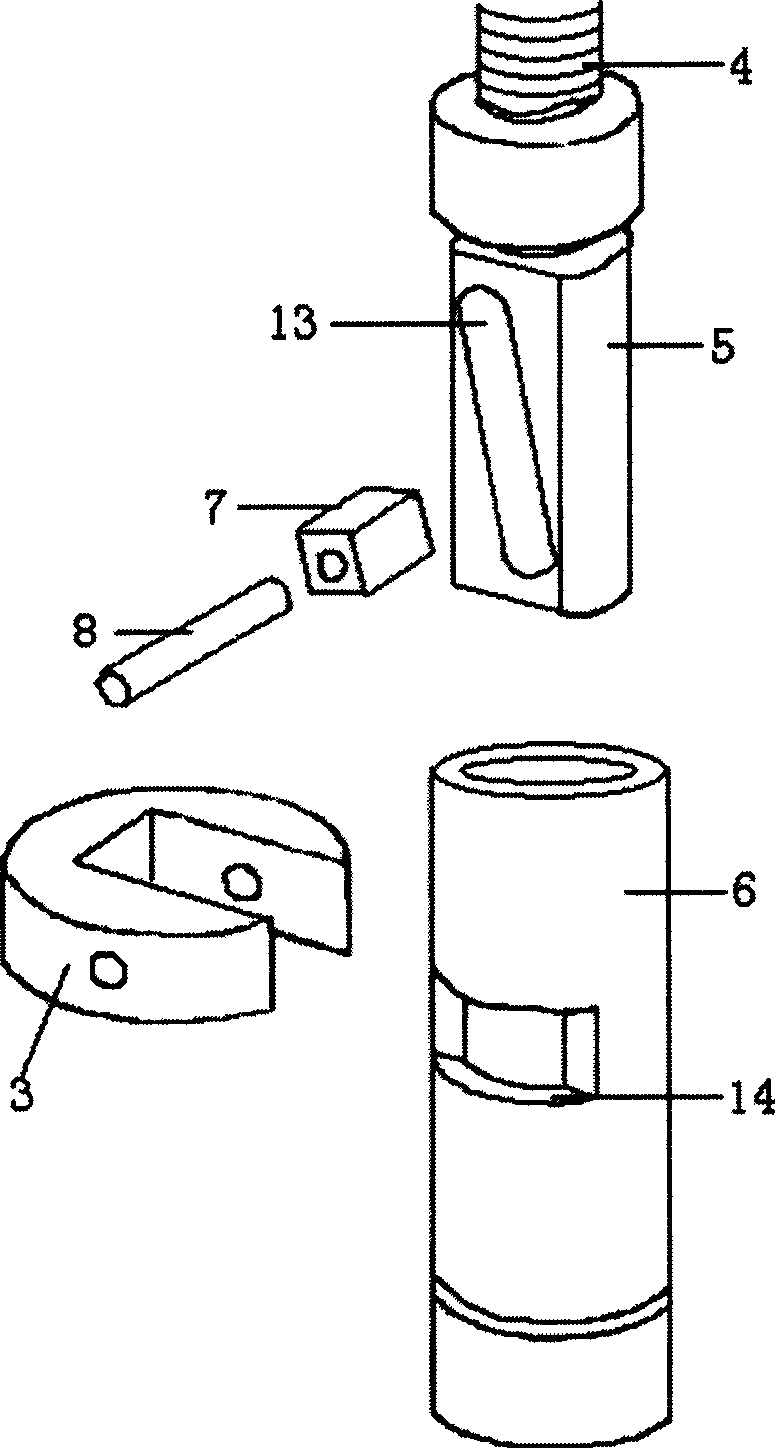

[0012] refer to figure 1 , 2 , the stroke adjustment mechanism of the metering pump, including the adjustment rod 4, the L-shaped shaft 5 fixedly connected to the adjustment rod 4 below the adjustment rod, the L-shaped shaft 5 is provided with a chute 13, and the chute 13 A pin sleeve 7 is installed inside, and a latch 8 is inserted in the pin sleeve 7. The L-shaped shaft 5 is covered with a shaft sleeve 6, and the L-shaped shaft sleeve 6 is supported on the bearing 12. Two grooves 14 are symmetrically provided on the outer circumference of the shaft sleeve 6, and an eccentric wheel 3 with a gap is set on the shaft sleeve 6 through the gap and the groove 14 on the shaft sleeve, and the latch 8 Pass through the groove on the bushing and the eccentric wheel 3; the bushing 6 is connected with the worm 11 and the worm wheel 10, the eccentric wheel 3 is connected with the connecting rod 1, and there is a connection between the connecting rod and the eccentric wheel Bushing 2.

...

Embodiment 2

[0015] refer to figure 1 , 2 , a protruding support ring 9 is arranged outside the shaft sleeve, and the connecting rod 1 is arranged on the support ring 9 . The support ring 9 is used to support the connecting rod 1 . The remaining implementation modes are the same as the first embodiment. During the working process of the connecting rod 1, due to the drop of its own weight, the gap between the connecting rod 1 and the bushing 2 is uneven, the lubrication is poor, and serious problems such as partial wear and easy failure occur. After the support ring is installed, the wear of the connecting rod and the connecting rod bushing can be improved. Significant improvement.

Embodiment 3

[0017] refer to figure 1 , 2 , The bearing supporting the bushing is an angular contact ball bearing. The remaining implementation modes are the same as the first embodiment. The axial positioning of the angular contact ball bearing is good, which can prevent the axial movement beyond the design range, ensure the position of the worm 10 and the worm wheel 11, and prevent the eccentric wear of the worm 10 and the worm wheel 11 due to excessive axial movement , Improve product reliability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com