Concrete pump with vibration type hopper fence

A concrete pump, vibrating technology, which is applied in the processing of building materials, earth-moving drilling, wellbore lining, etc., can solve the problems of low vibration frequency, low efficiency, and increase the maintenance cost of concrete pumps, so as to facilitate replacement and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

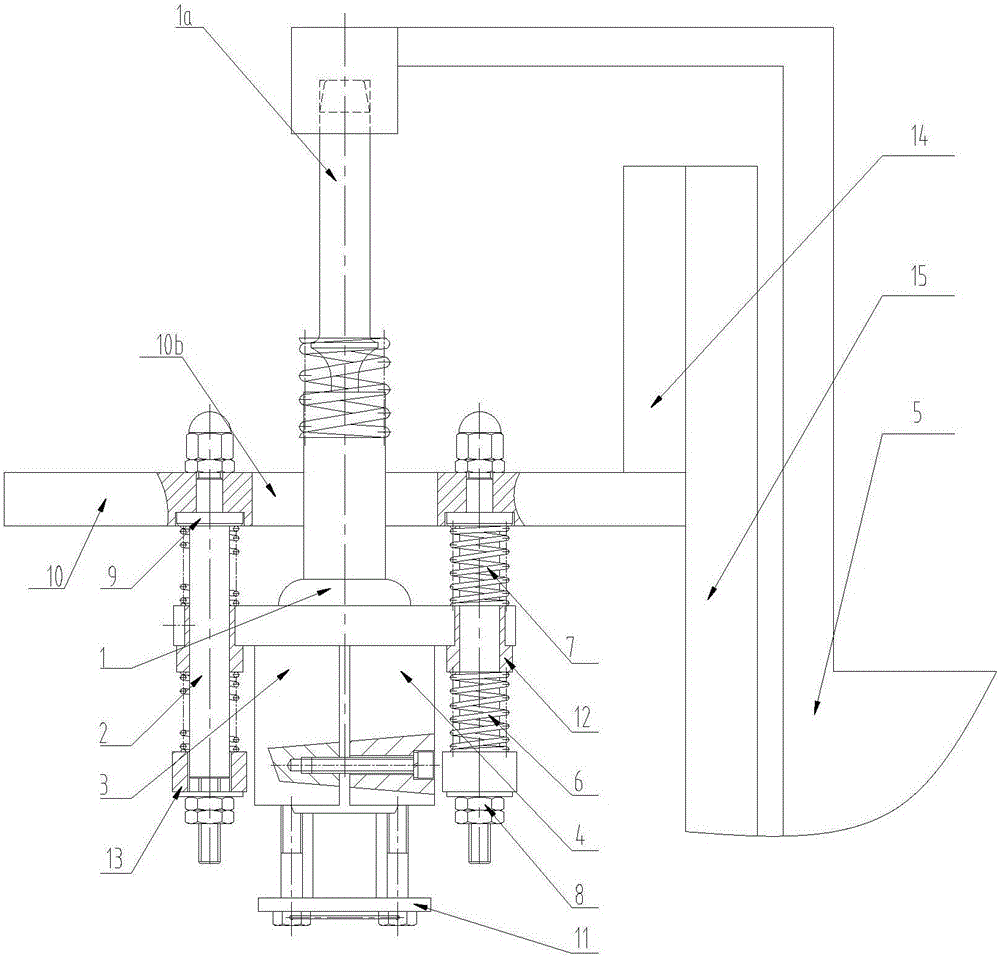

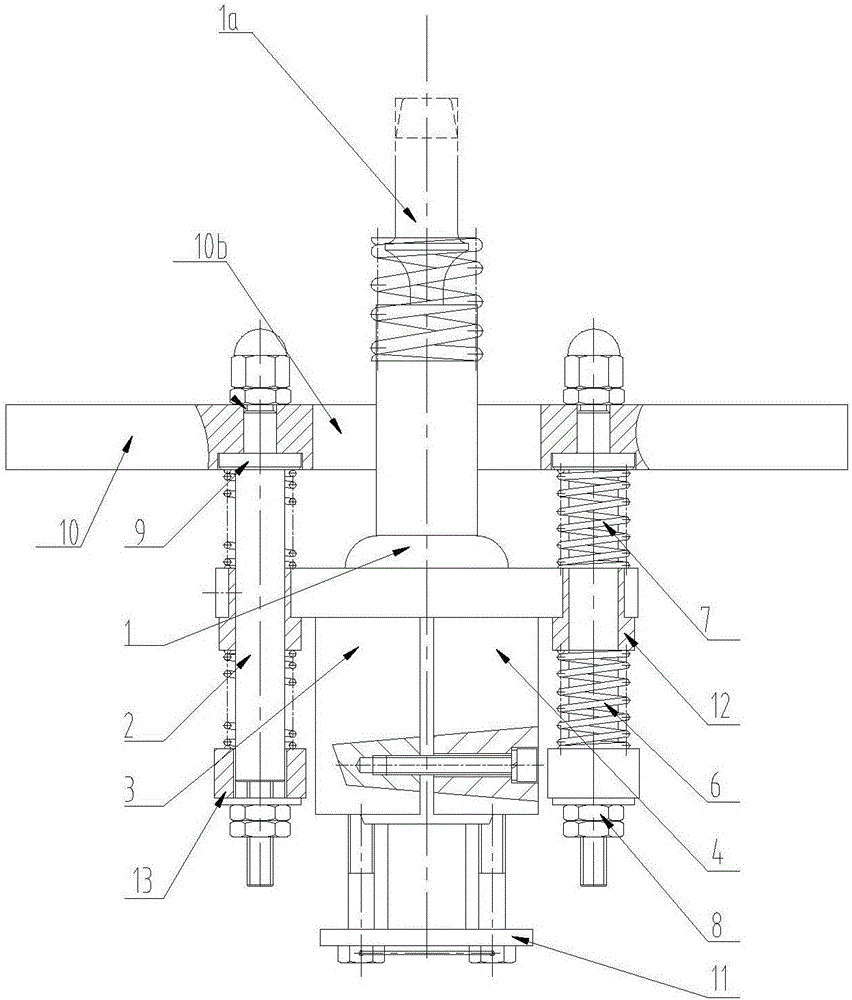

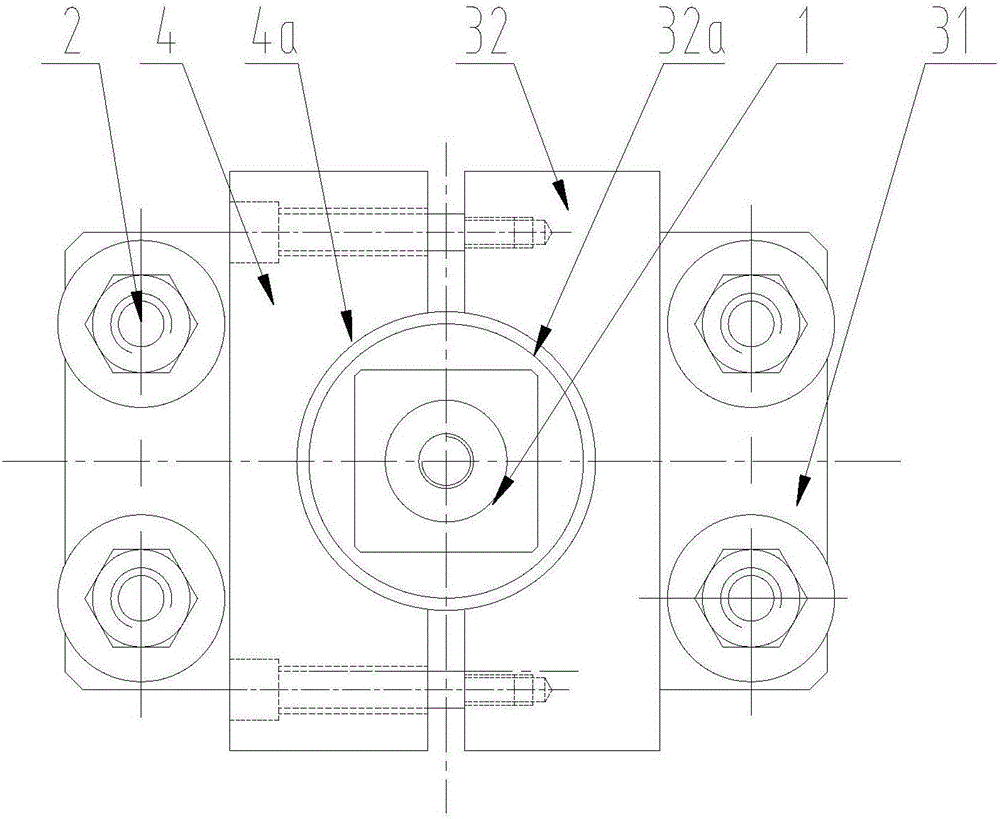

[0029] see Figure 1 to Figure 5, is a concrete pump with a vibrating hopper fence, comprising a concrete mixing device, a hopper and a fence arranged in the hopper, and a vibrating device for driving the fence, the vibrating device includes a pneumatic vibrator 1, A device for clamping a pneumatic vibrator, a guide rod 2, the device for clamping a pneumatic vibrator is composed of a clamping seat 3 and a clamp 4, and the clamping seat 3 includes a bottom plate 31 and a clamping base Seat 32, the bottom plate 31 is provided with a relief through hole 31a and a plurality of guide rod through holes 31b, the relief through hole 31a is located in the center between the plurality of guide rod through holes 31b, The seat 32 is fixed on the lower end surface of the base plate 31, and is located on one side of the through hole 31a. The clamping base 32 is provided with an arc groove 32a on the side facing the axis line of the through hole 31a. The arc groove 32a The center of the arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com