Lubricating oil allocation device for automobile part maintenance

A technology of auto parts and lubricating oil, which is applied in the field of lubricating oil configuration equipment for auto parts maintenance, which can solve the problems of insufficient configuration and low configuration efficiency, and achieve the effect of increasing configuration speed, stirring speed and stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

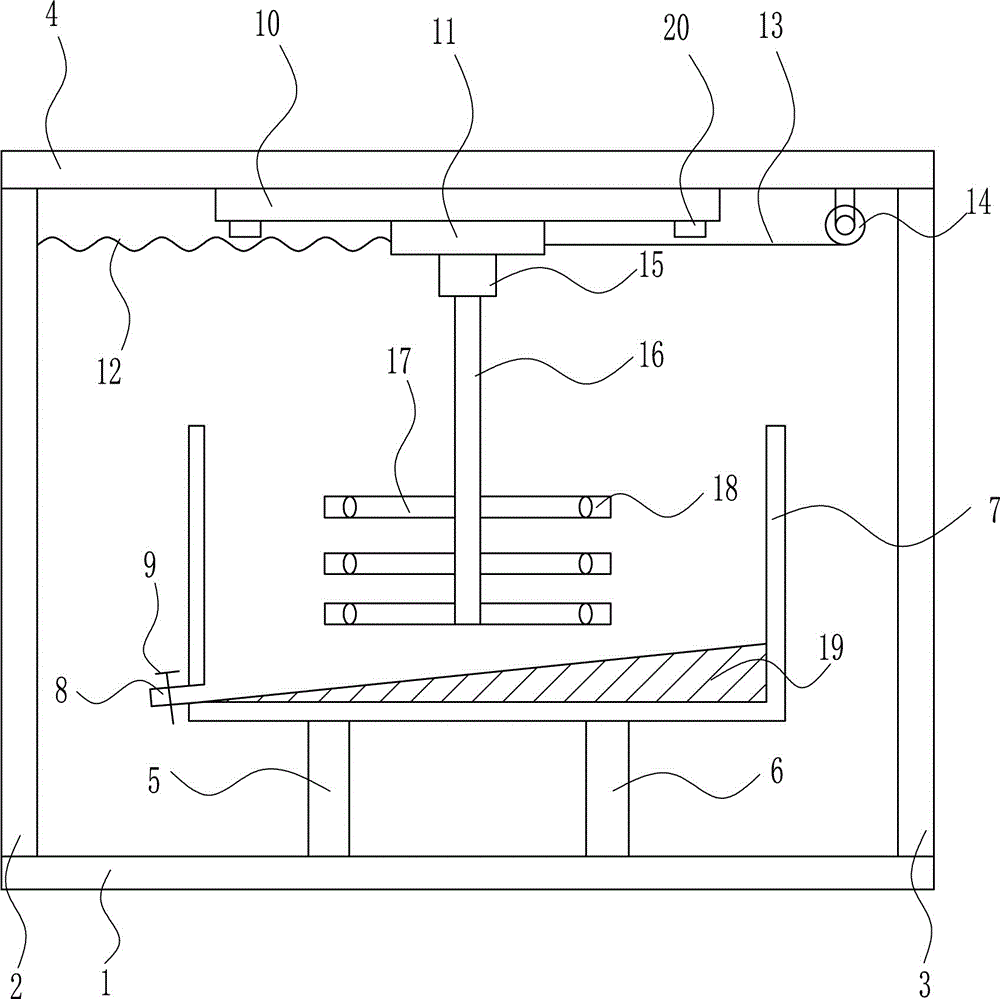

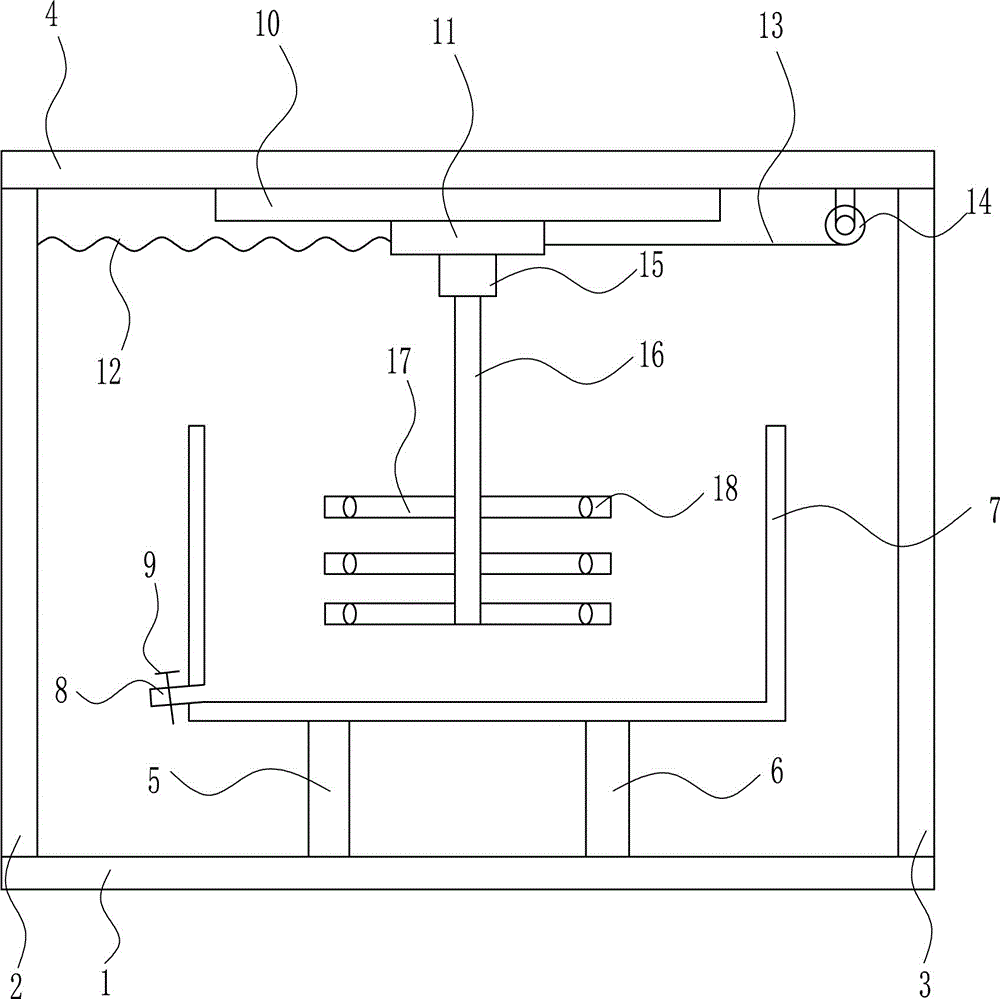

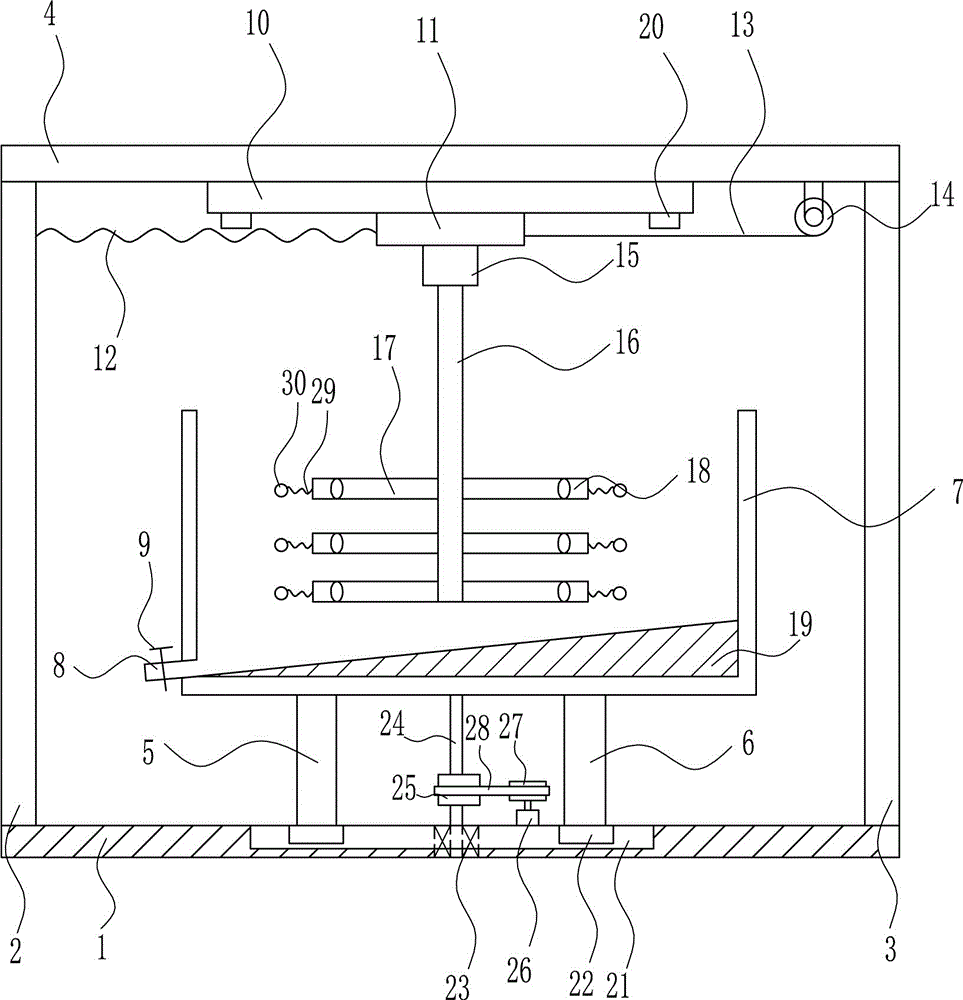

[0036] A lubricating oil configuration equipment for auto parts maintenance, such as Figure 1-7As shown, it includes bottom plate 1, left frame 2, right frame 3, top plate 4, first pole 5, second pole 6, configuration frame 7, discharge port 8, electric control valve 9, slide rail 10, moving Block 11, first spring 12, pull wire 13, electric reel 14, first motor 15, stirring rod 16 and stirring blade 17, left frame 2 and right frame 3 are symmetrically connected by welding at the left and right ends of the bottom plate 1 A top plate 4 is connected by welding between the tops of the left frame 2 and the right frame 3, and a first strut 5 and a second strut 6 are symmetrically connected in the middle of the top of the bottom plate 1 by a bolt connection, and the first strut 5 and the The top of the second pole 6 is connected with the configuration frame 7 by means of bolt connection, the bottom of the left wall of the configuration frame 7 is provided with a discharge port 8, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com