Efficient grinding fluid preparation device for maintenance of electrical and mechanical equipment

A technology for electrical machinery and grinding fluid, applied in the field of high-efficiency preparation devices for grinding fluid for maintenance of electrical machinery and equipment, can solve the problems of slow preparation speed, uneven stirring, inconvenient movement, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

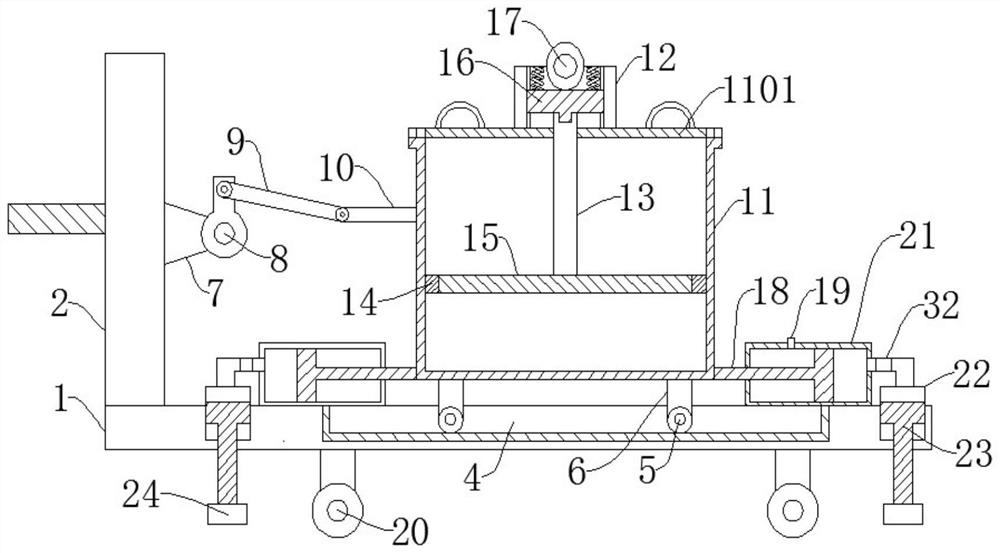

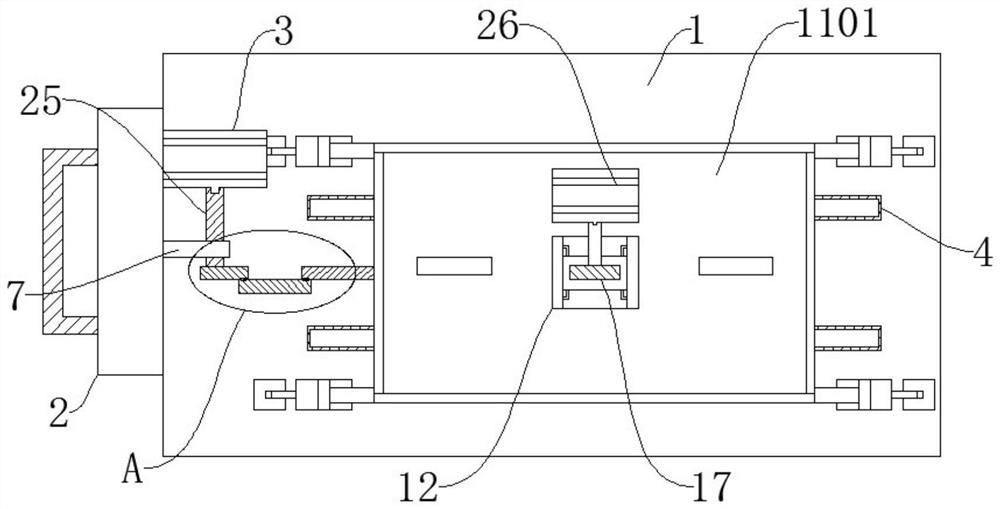

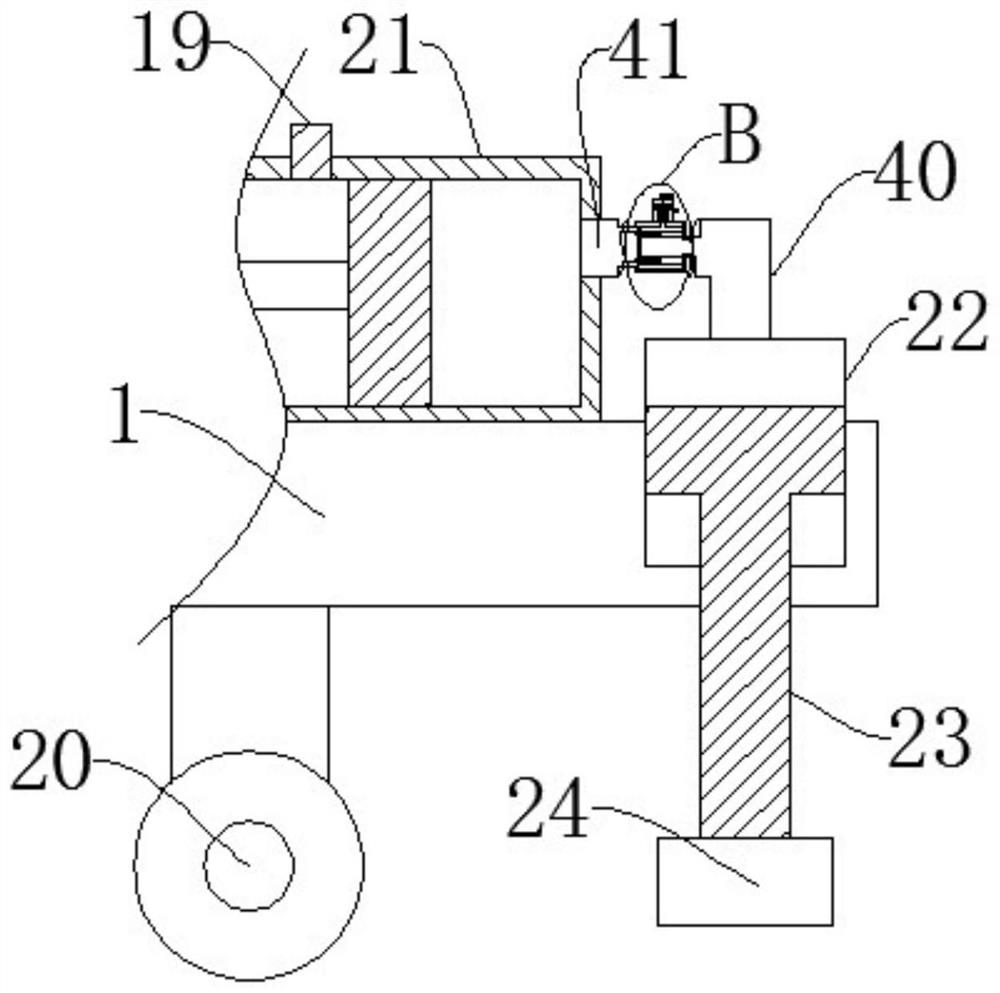

[0029] refer to Figure 1-7, an efficient preparation device for grinding fluid for maintenance of electrical mechanical equipment, comprising a base 1 and a mixing box 11, the base 1 is provided with a first chute 4, and the bottom sides of the mixing box 11 are fixedly connected with support rods 6 to support The bottom of the rod 6 is rotatably connected with a pulley 5, the pulley 5 rotates in the first chute 4, the side of the base 1 is fixedly connected with the vertical plate 2, and the side of the vertical plate 2 close to the mixing box 11 is fixedly connected with the first motor 3, The output end of the first motor 3 is fixedly connected with a first rotating shaft 25, the first rotating shaft 25 is rotatably connected with the mounting frame 7, the mounting frame 7 is fixedly connected with the vertical plate 2, and the first rotating shaft 25 is rotatably connected with one end away from the first motor 3 There is a crank 8, the other end of the crank 8 is rotatab...

Embodiment 2

[0032] refer to Figure 1-7 , a high-efficiency preparation device for grinding fluid for maintenance of electrical mechanical equipment, which is basically the same as in Embodiment 1, and furthermore: the upper end of the stirring box 11 is provided with a box cover 1101, and a second motor 26 is fixedly connected to the box cover 1101. The output end of the second motor 26 is fixedly connected with the cam rotating device 17, and the side of the case cover 1101 near the second motor 26 is fixedly connected with the fixed box 12, and the cam rotating device 17 rotates in the fixed box 12, and the fixed box 12 is provided with a slide A third motor 16 is slidingly connected in the chute, a return spring 28 is fixedly connected to the upper end of the third motor 16, the other end of the return spring 28 is fixedly connected to the fixed box 12, and the output end of the third motor 16 is fixedly connected to a The second rotating shaft 13, the other end of the second rotating...

Embodiment 3

[0034] refer to Figure 1-7 , a high-efficiency preparation device for grinding fluid for maintenance of electrical machinery equipment, which is basically the same as that of Embodiment 1, and furthermore: the pressing plate 15 is provided with several round holes, so that the raw materials in the mixing box 11 are continuously extruded through the round holes , and then stir more thoroughly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com