Automobile part drying case

A technology of auto parts and drying box, which is applied in coating, surface pretreatment, transportation and packaging, etc. It can solve the problems of uneven drying, difficult drying, and low drying efficiency, so as to improve drying efficiency , good ventilation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

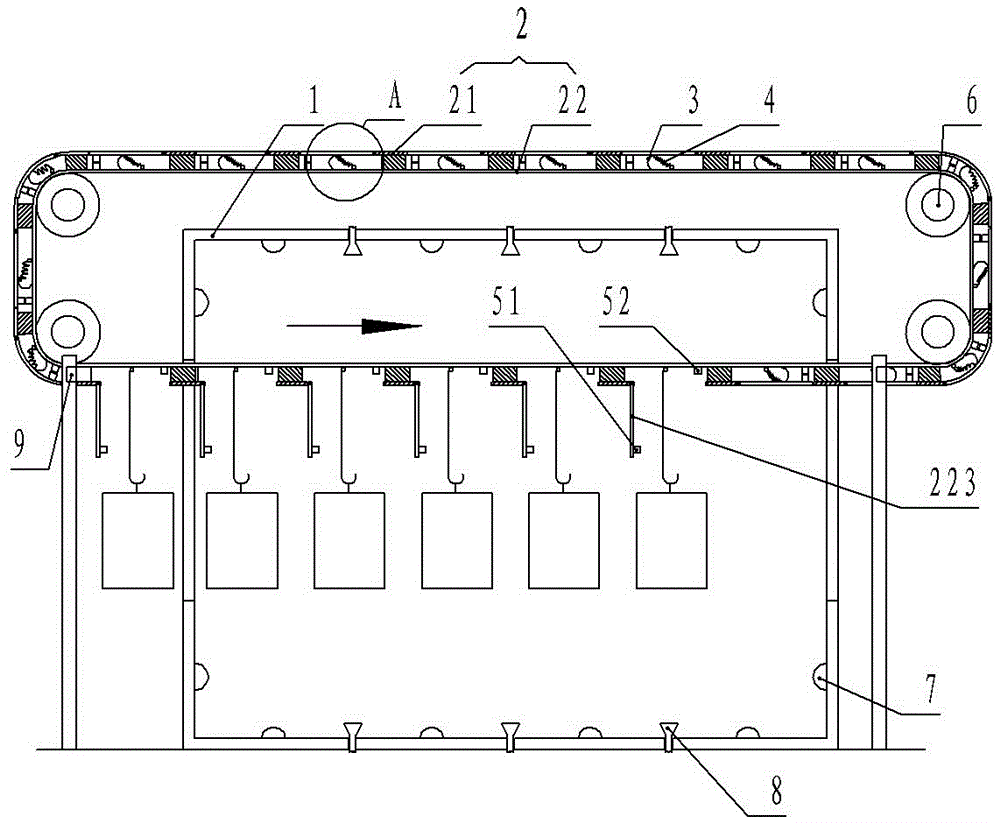

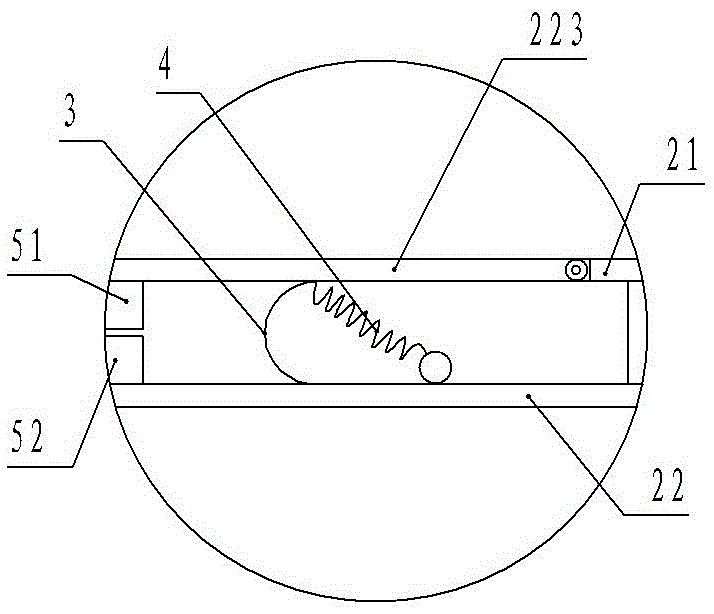

[0012] figure 1 The auto parts drying box shown includes a box body 1 and an endless conveyor belt 2. The opposite side walls of the box body 1 are provided with doors for the auto parts to enter or exit, and the inner wall of the box is provided with air nozzles 8 and drying Dry spotlight 7, the descending belt of the endless conveyor belt 2 passes through the door and is installed in the box body 1; the endless conveyor belt 2 is composed of an inner ring belt 22 and an outer ring belt 21, and there is a A plurality of socket heads 3 fixed on the inner ring belt 22 by spring cables 4; the socket heads are hooks or clips; corresponding to the outer ring belt 21 of each socket head 3, a plurality of socket heads 3 are stretched out or contracted. The switch plate 223 that enters is provided with the first electromagnet block 51 on the switch plate 223;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com