Detection device for bearing base of thrust ball bearing

A technology of thrust ball bearings and testing equipment, which is applied to chemical instruments and methods, cleaning methods using liquids, cleaning methods and appliances, etc. It can solve the problems of insufficient system and comprehensive measurement items, inconvenient transportation and movement, and bulky equipment. Achieve the effect of simple structure, no need for manual operation, and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

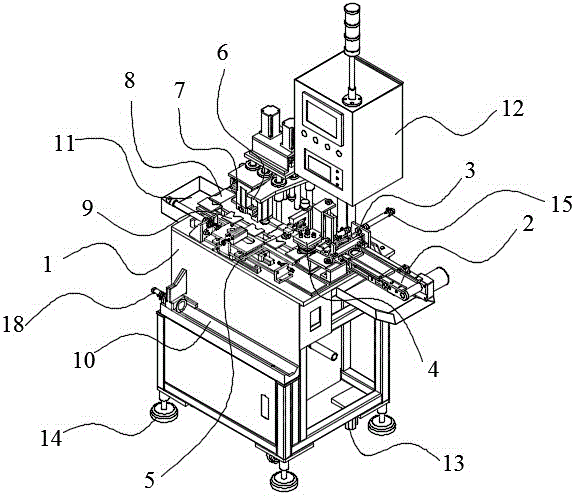

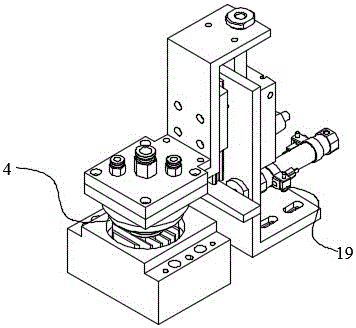

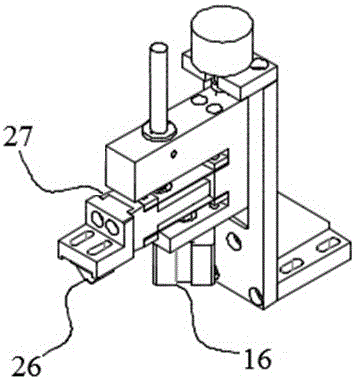

[0024] Thrust ball bearing housing testing equipment in this embodiment, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, it includes: a frame 1, a conveyor belt 2, a push-pull rod 3 arranged at equal intervals on one side of the upper surface of the frame, a flushing nozzle 4, a groove depth measuring head 5, an inner diameter measuring head 6, and an outer diameter measuring head 7. Qualified product turning and unloading table 8, the bearing seat push-pull transmission plate 9 arranged on the other side of the upper surface of the frame 1 and the finished product groove 10 arranged on the side of the frame 1 outside the bearing seat push-pull transmission plate 9; push-pull rod 3. Flushing nozzle 4, groove depth measuring head 5, inner diameter measuring head 6, outer diameter measuring head 7, qualif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com