One-time forming method for S-shaped pouring gate of large-sized shell casting

A molding method and serpentine technology, applied in casting molding equipment, mold components, molds, etc., to achieve the effect of reducing processes, reducing dosage, and reducing sand consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

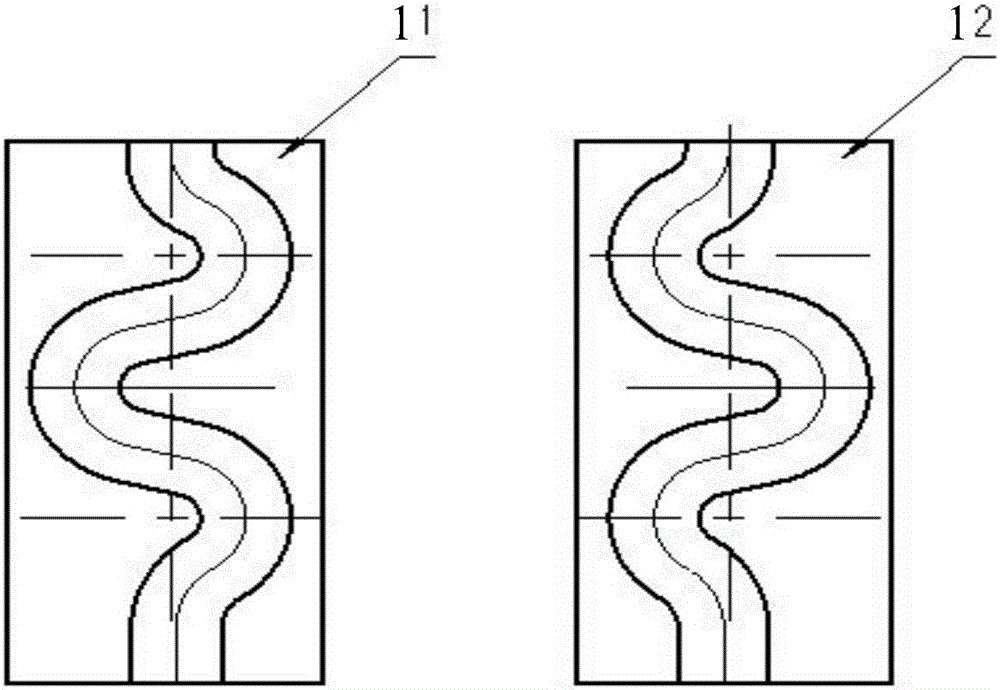

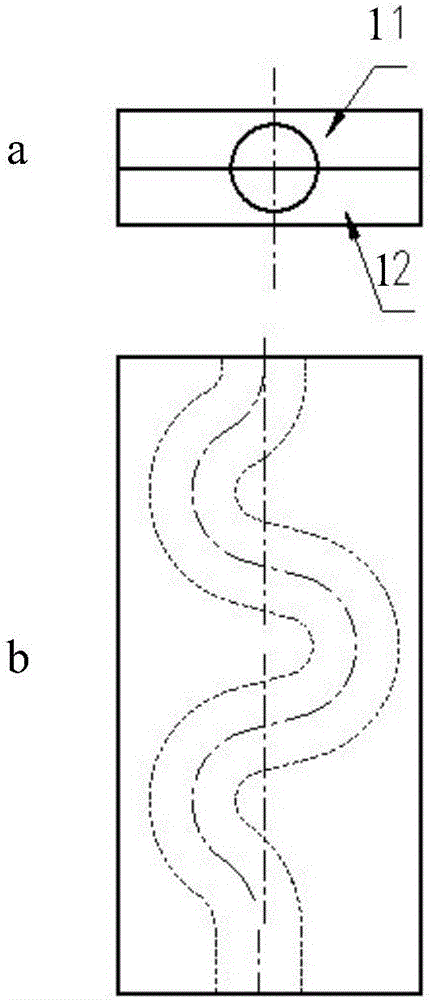

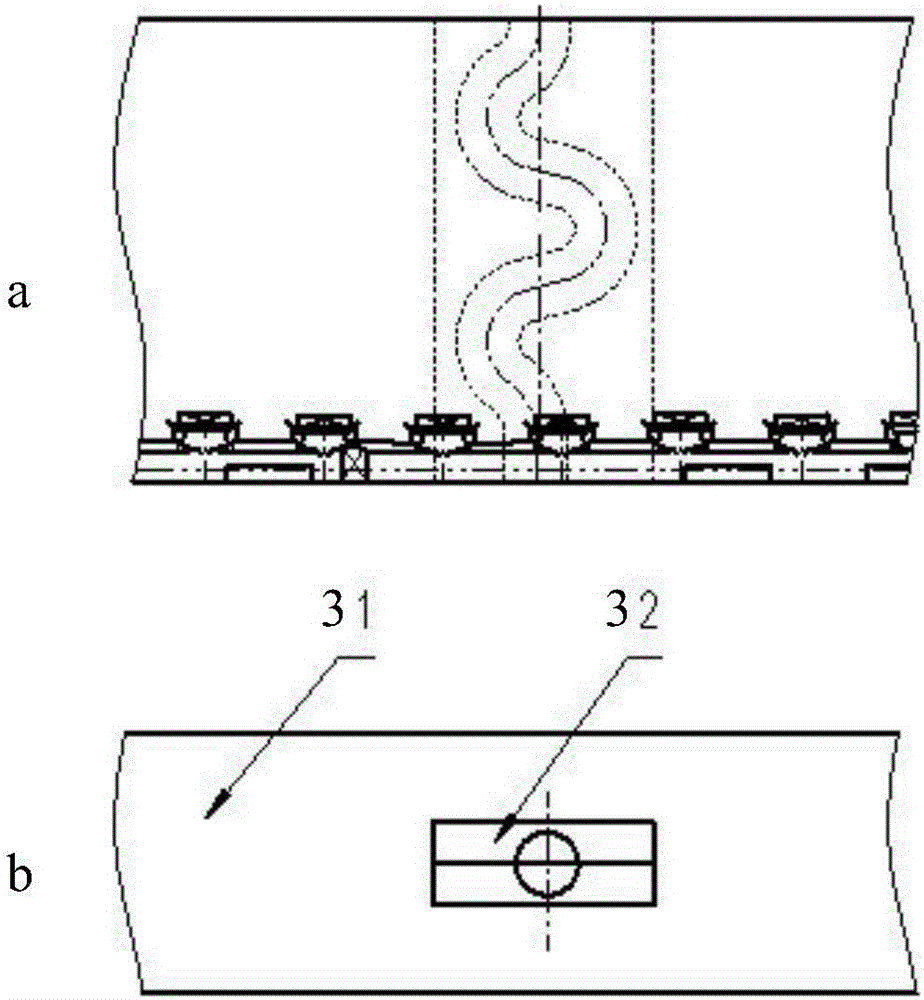

[0031] The invention specifically relates to a process for directly forming a serpentine runner by using resin sand, water glass sand, cement sand and the like. In the production process of castings, the part used to receive molten metal and fill the mold cavity in an orderly manner is called the gating system. The gating system is generally divided into straight sprue, horizontal sprue, and inner sprue. In the category of sprue, the gating system of this structure is often used in the production of some large complex thin-walled castings. The serpentine sprue has a multi-"S"-shaped structure. The filtering effect can avoid the splash of molten metal caused by the excessive drop of ordinary sprue, reduce the generation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com