Conical tooling

A tooling and cone-shaped technology, applied in the field of cone tooling, can solve the problems of large resin sand manpower, increased production costs, waste of printing resources, etc., to achieve the effects of reducing manufacturing costs, preventing axial movement, and reducing the amount of sand consumed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A technical solution of the embodiment of the invention will be further elaborated in detail with reference to the accompanying drawings of the invention.

[0024] In the present invention, unless otherwise specified and limited, the terms should be understood in a broad sense, and those skilled in the art can understand the specific meanings of the terms in the present invention according to specific situations.

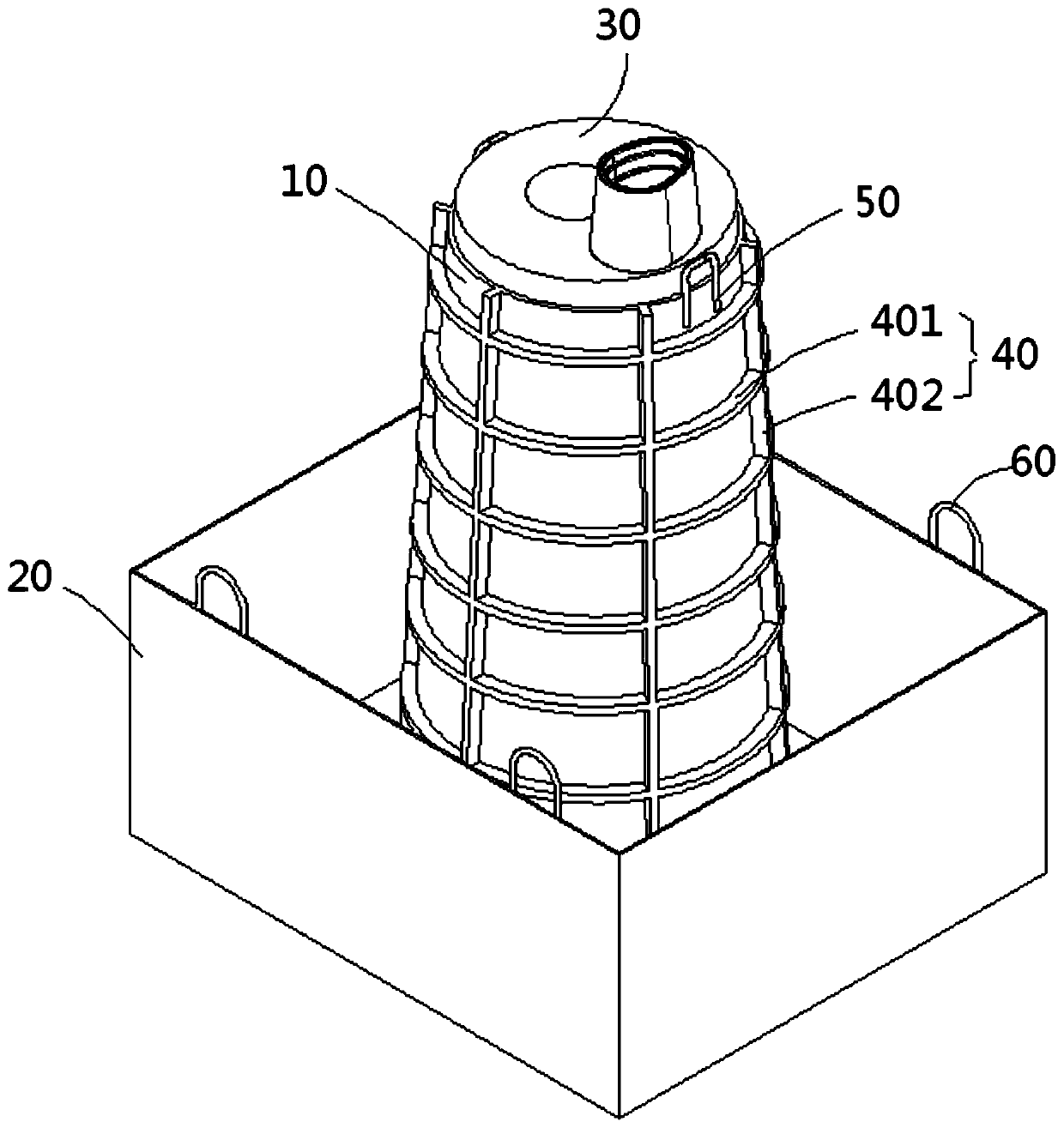

[0025] Please see attached figure 1 As shown, the present invention provides a tapered tooling including a tooling main body 10 and a tooling tray 20. The upper and lower parts of the tooling main body 10 are open structures, and the inner contour of the tooling main body 10 is a tapered structure enlarged from top to bottom. The tray 20 is arranged below the tool body 10 , and the sand mold 30 is assembled inside the tool body 10 , and the inner contour of the tool body 10 is the same as the taper of the outer contour of the sand mold 30 .

[0026] In this ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com