U-shaped vehicle assembling tool

A tooling and U-shaped technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of low production efficiency and achieve the effect of improving production efficiency and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

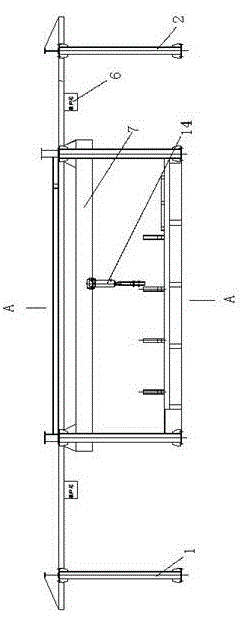

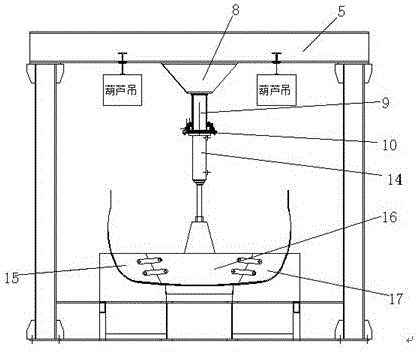

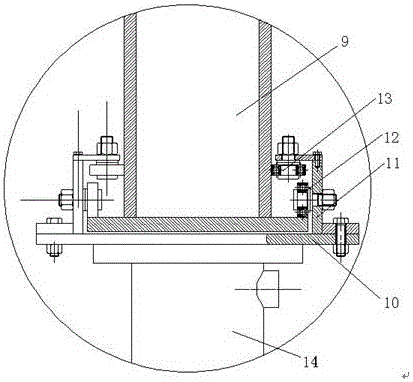

[0020] See attached picture.

[0021] A U-shaped car assembly tooling, including a front and rear feeding and discharging system and an intermediate pressing system between them. The front and rear feeding and discharging system includes a feeding and discharging frame. Two side-by-side left and right beams are erected, and suspension beams 5 are arranged between the left and right beams at both ends. Two spaced hoist cranes 6 are respectively installed on the suspension beams 5. The middle pressing system includes The fixed beam 7 on the outside of the crossbeam and supported by the column, the lower end of the fixed beam 7 is equipped with a moving mechanism that cooperates with it, and the bottom end of the moving mechanism is equipped with a pressing mechanism.

[0022] The moving mechanism includes a turntable 8, the two sides of the turntable 8 guide and cooperate with the fixed beam, the two sides of the turntable are provided with hobbing gears, and the hobbing teeth c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com