Fixture suitable for flange part machining

A part processing and flange technology, which is applied in the field of fixtures, can solve the problems that the fixtures cannot realize or partially realize the angular orientation, end face and center positioning of the parts to be processed, the accuracy of the clamping position is not enough, and the processing efficiency is low, etc., to achieve The effect of shortening the loading time, simple structure, and convenient loading of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

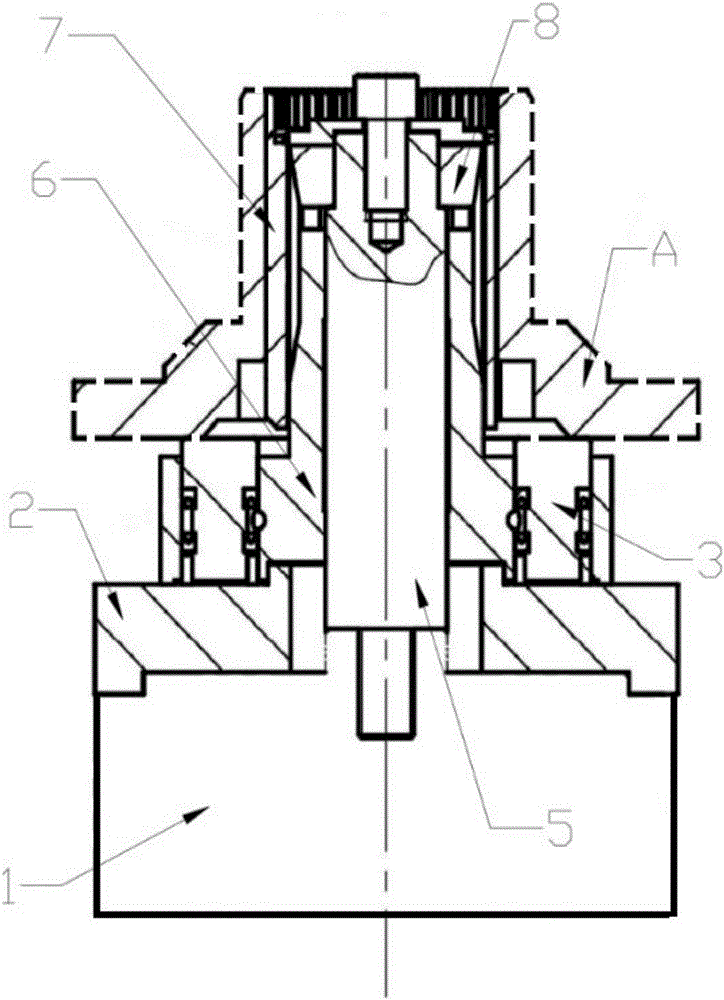

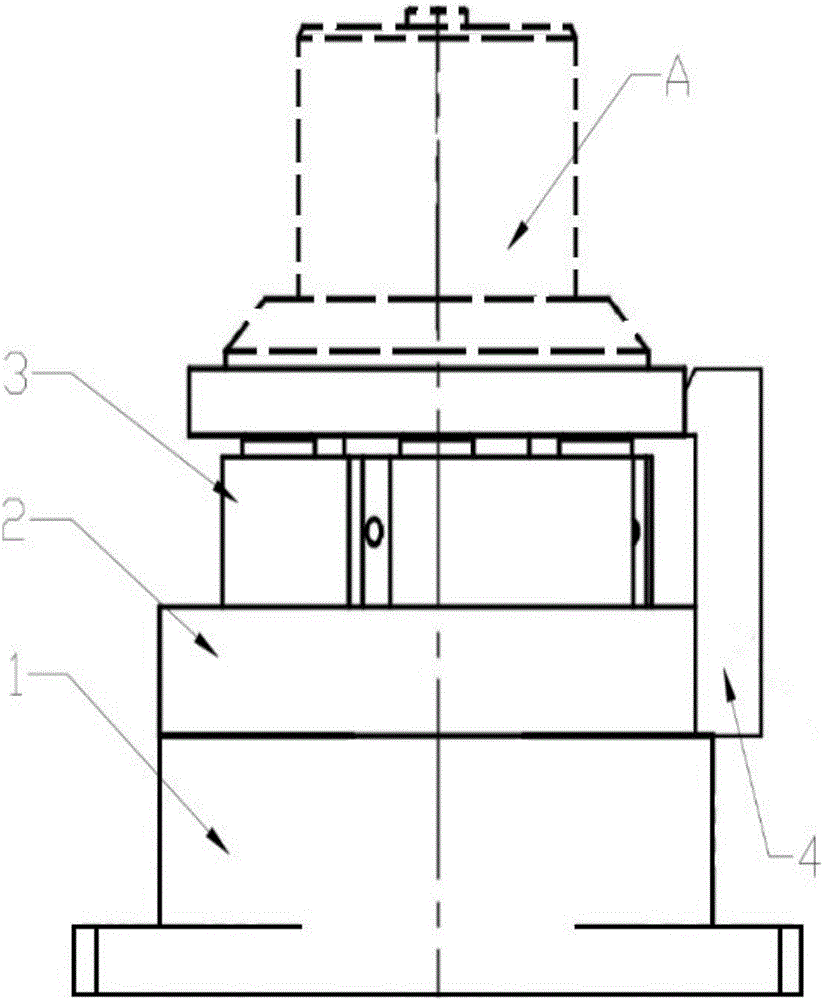

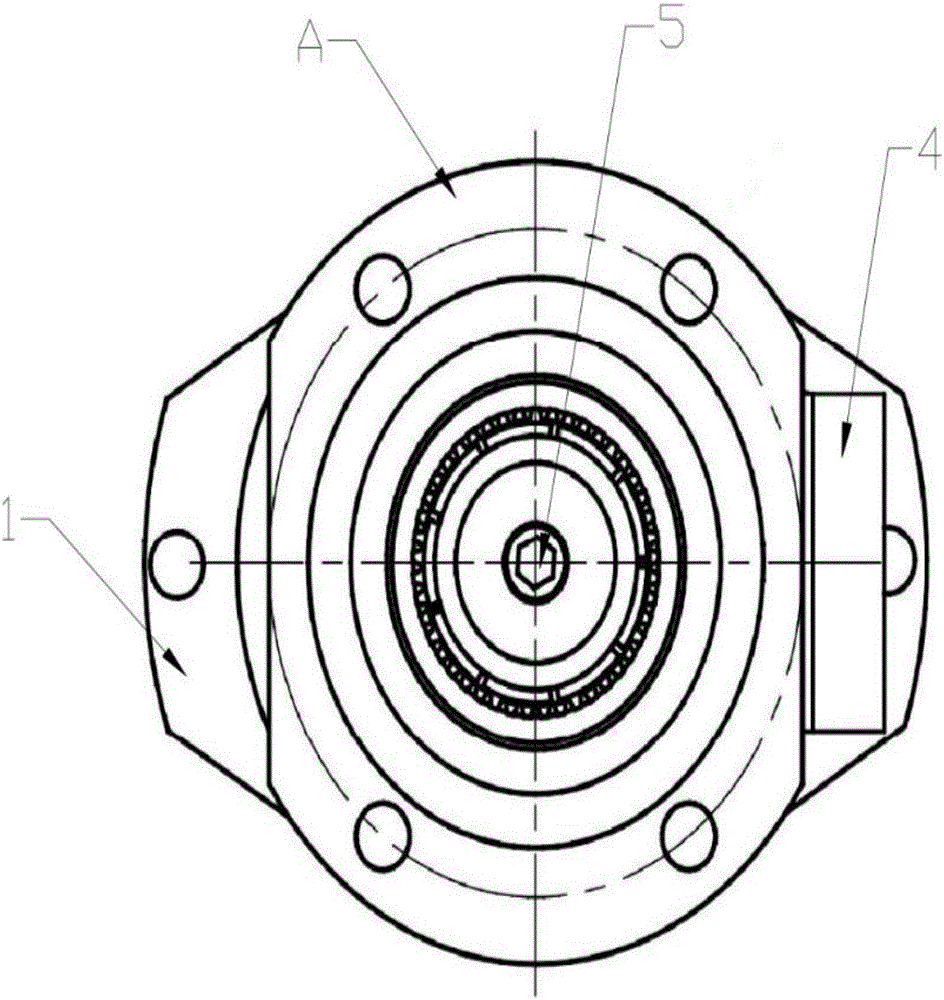

[0027] Embodiment: A fixture suitable for machining flange parts, including a chuck cylinder 1 and a support 2, wherein the chuck cylinder 1 is a straight cylindrical cylinder; the upper end of the chuck cylinder 1 is fixed with a support 2. A floating positioning block 3 is fixed above the support 2; an elastic angular positioning block 4 is fixed on the side of the support 2; the central position of the chuck cylinder 1 is connected with a tie rod 5 in the vertical direction; 5 sets of tie rods There is a tensioning mandrel 6; the outer side of the tensioning mandrel 6 is sleeved with a spline expansion sleeve 7; the outer sleeve of the spline expansion sleeve 7 is for processing flange parts A; the tensioning mandrel 6 is away from the chuck One end of the oil cylinder 1 is sleeved with a tensioning block; the chuck oil cylinder 1 is provided with two ear seats on the side near the lower end surface, the two ear seats are opposed to the chuck oil cylinder 1, and each ear seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com