High speed ceiling nail having gunpowder

A technology of ceiling nails and gunpowder, applied in nailing tools, manufacturing tools, etc., can solve problems such as poor support effect, low efficiency of operation mode, and misoperation, so as to simplify ceiling operation, improve operation efficiency, and prevent misoperation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The invention will be further described below by means of drawings and specific embodiments. The specific embodiments described here are only for explaining the invention, and are not intended to limit the protection scope of the present invention.

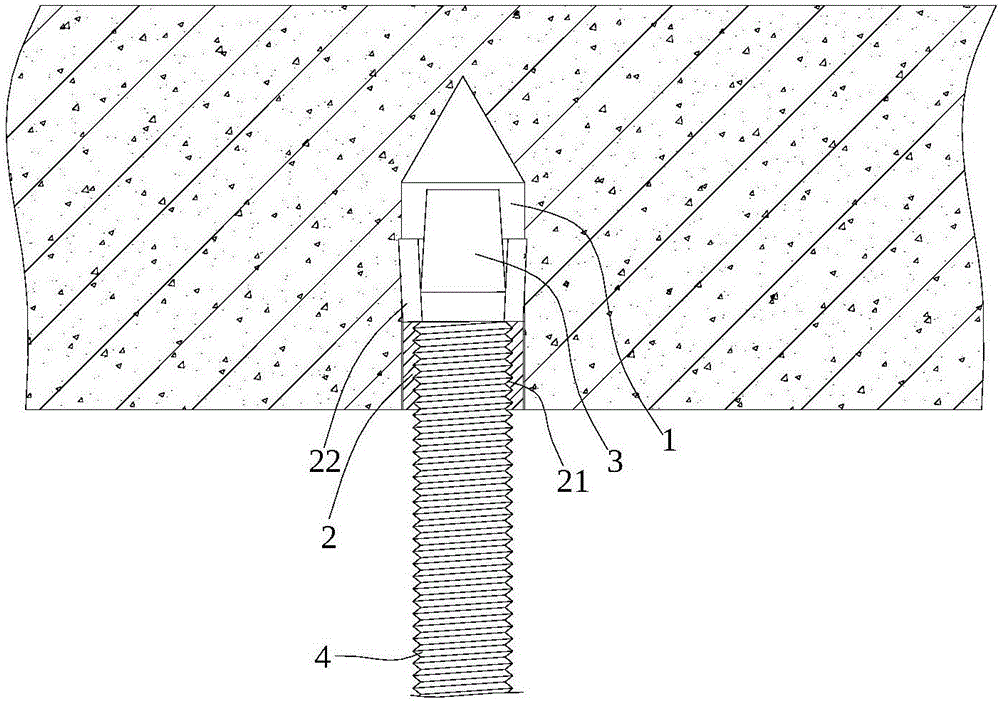

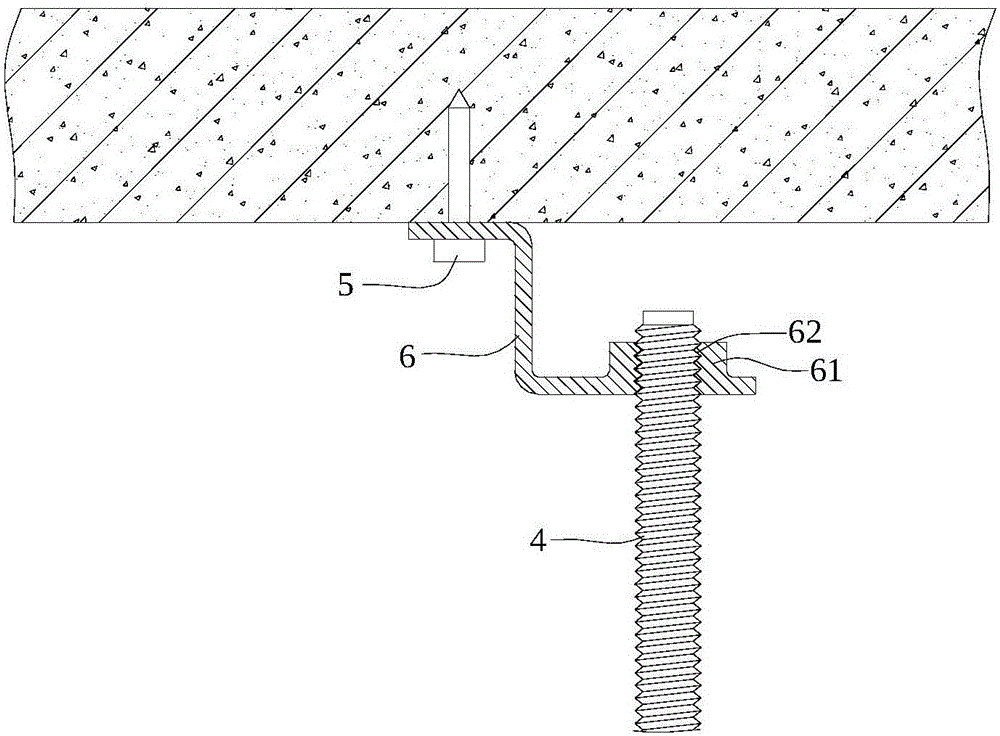

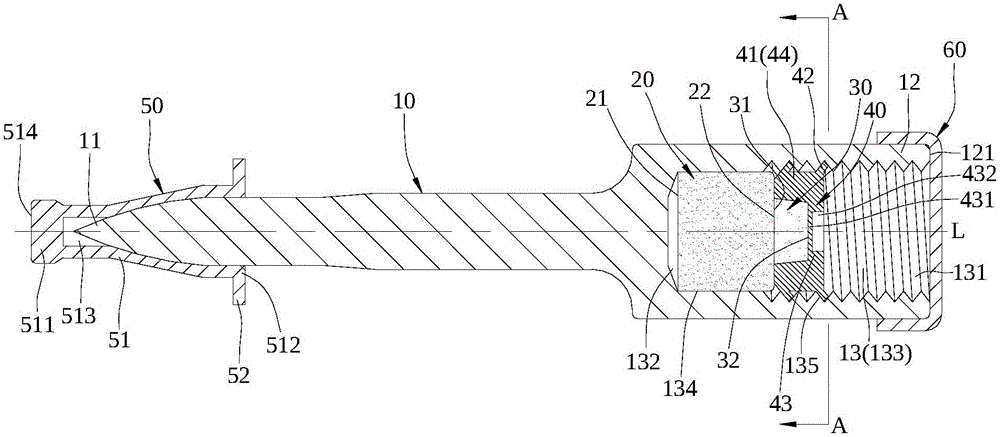

[0014] High-speed ceiling nails with gunpowder, such as Figure 3 ~ Figure 5 As shown, it includes a body 10 , propellant powder 20 , primer powder 30 , primer seat 40 , shield 50 and cover 60 .

[0015] The main body 10 extends along the central axis L and is in the shape of a stepped rod. One end of the main body 10 is the firing tip 11, and the other end is the impacted part 12. The impacted part 12 has an end surface that is opposite to the firing tip 11 and perpendicular to the central axis L. 121, the impacted portion 12 has an accommodating chamber 13 recessed toward the firing tip 11, the accommodating chamber 13 has an open end 131 adjacent to the end face 121 and a bottom end 132 opposite to the open end 131, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com