A non-adhesive process for material-free backing roll cutting and non-adhesive

A technology without base material and film, which is applied in metal processing and other directions, can solve the problems that are not conducive to mass production, the cleanliness of glue removal is not high, and the work efficiency is low, so as to facilitate industrial mass production, save labor, and save The effect of working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described below in conjunction with specific embodiment:

[0017] A kind of non-adhesive process of material-free back adhesive roll cutting, comprising the following steps:

[0018] Clamp and fix the non-substrate-backed film on the main shaft so that it rotates synchronously with the main shaft. The cutting round knife advances and retracts in a direction perpendicular to the main shaft of the non-substrate-backed film. The cutting edge of the cutting round knife Opposite to the direction of rotation of the substrate-free film at the tangent point;

[0019] The thickness of the double-sided adhesive on the non-substrate-backed roll is less than 0.1mm;

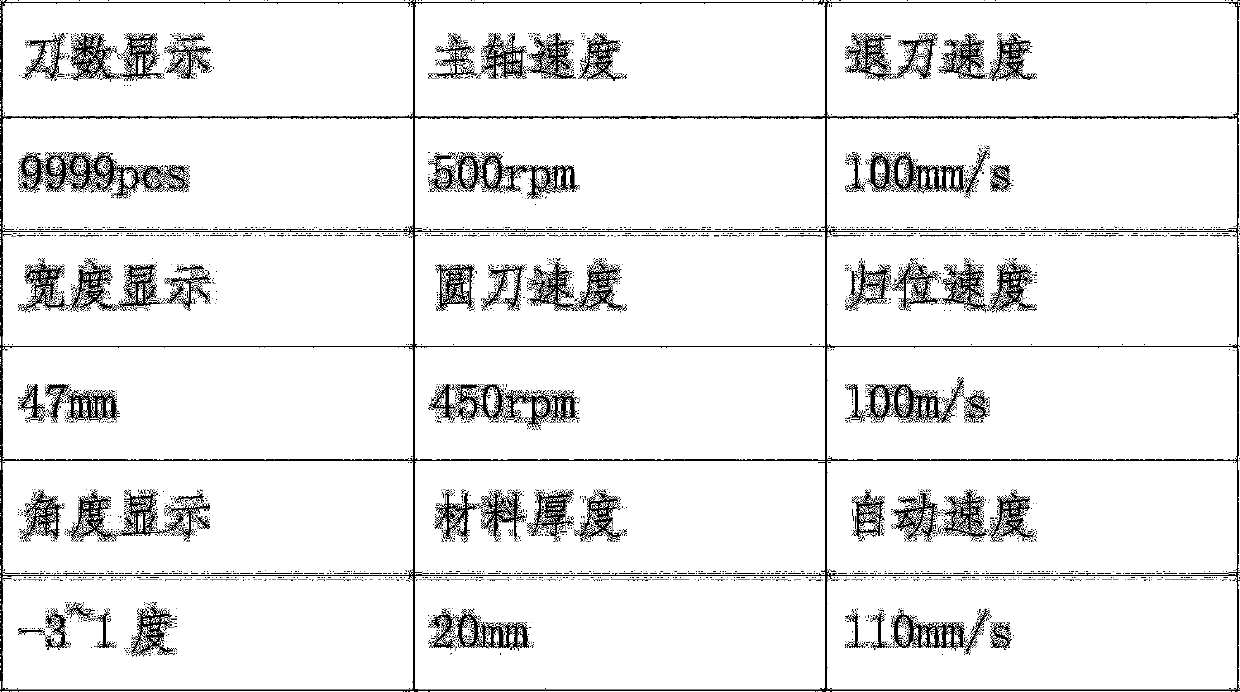

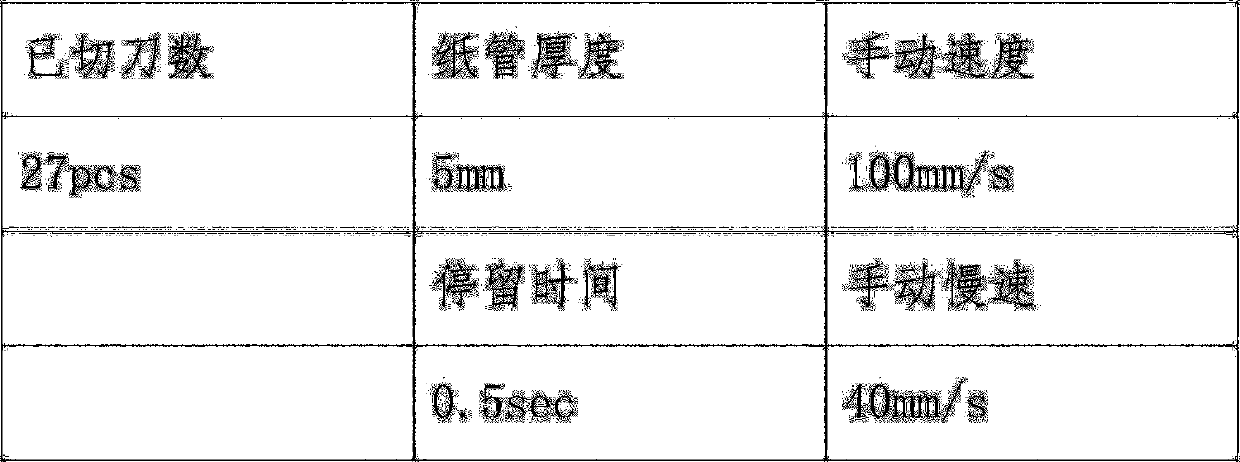

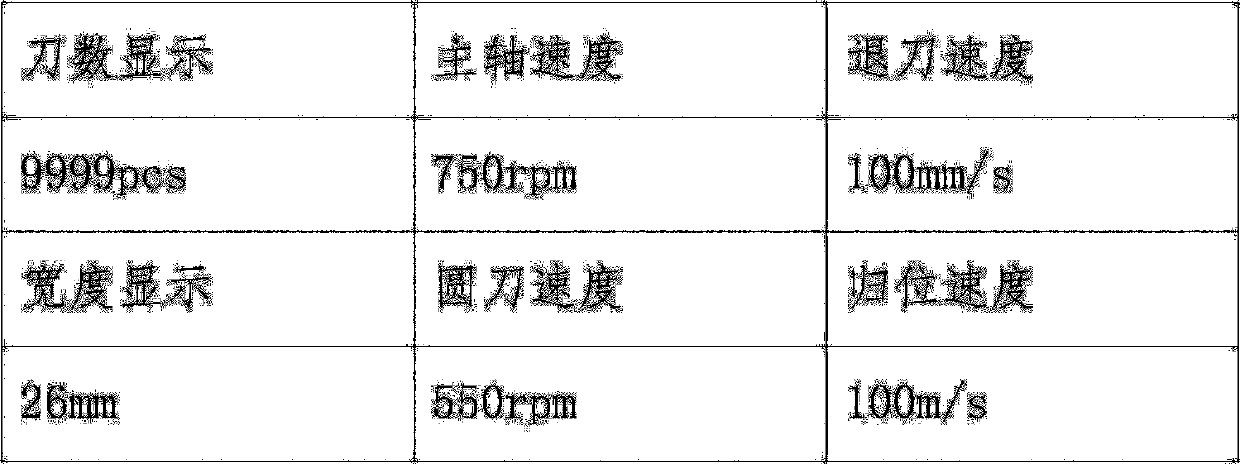

[0020] The speed of the main shaft is set at a constant speed of 700-750r / min;

[0021] The rotating speed of described material cutting circular knife is uniform speed 450-550r / min, and described material cutting circular knife feeds and cuts material sequentially according to single cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com