Pressure injection mold for shock pad

A shock-absorbing pad and mold technology, which is applied in the field of injection molds, can solve the problems of not effectively removing burrs, lengthening the processing process of rubber products, and consuming human resources, etc., and achieves the effects of accurate molds, improved production efficiency, and cost savings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

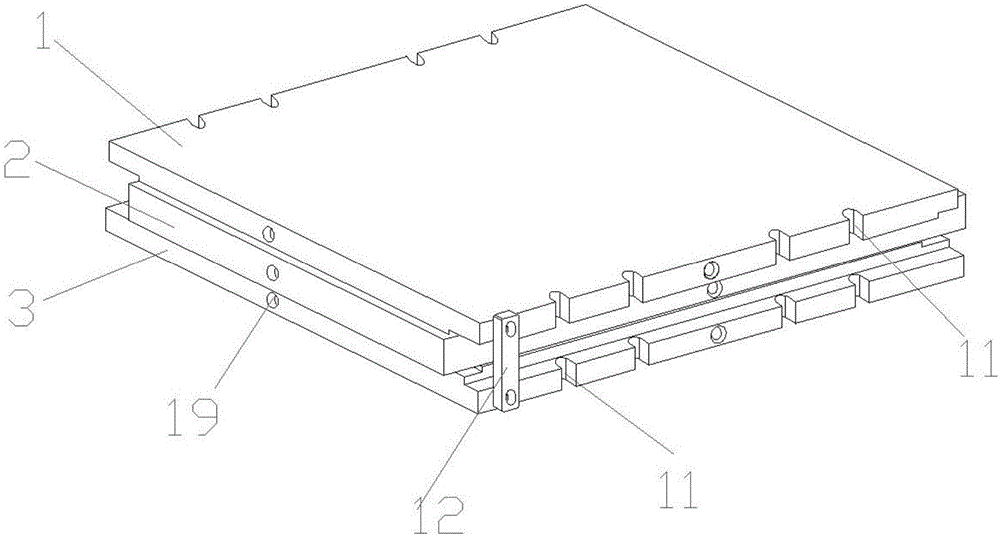

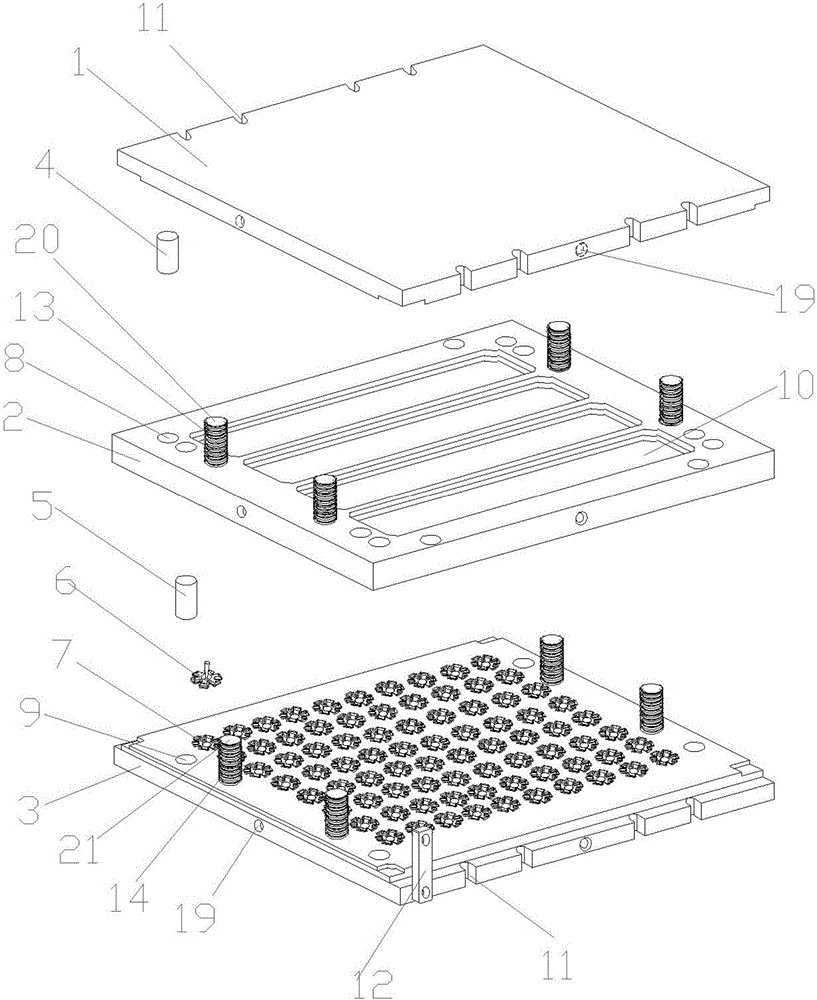

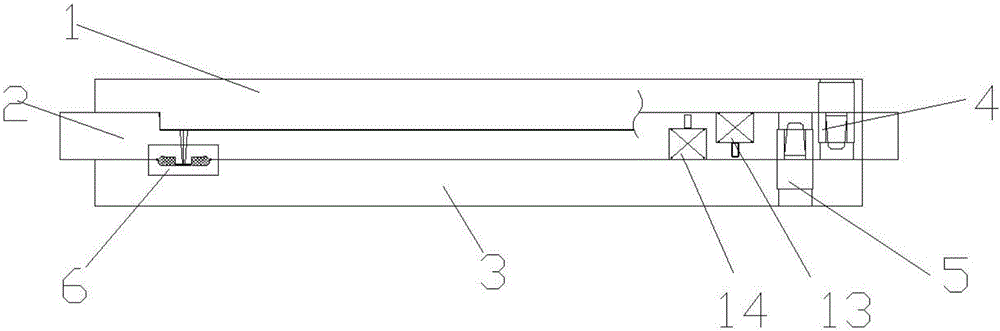

[0027] As shown in the figure, a shock absorbing pad injection mold of the present invention includes a mold and a heating and pressing mechanism. The mold includes a pressing plate 1, an upper template 2 and a lower template 3. Four fixing grooves 11 are respectively provided, and a hanging die hole 19 is provided on the side of the pressure plate 1 . The upper template 2 is provided with glue injection grooves 10, and the number of the glue injection grooves 10 is four, and several evenly distributed glue injection ports are arranged below the glue injection grooves 10, and the upper template 2 is also provided with a pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com