Coaxial input-output variable torque differential drive device

An input-output, differential drive technology, applied in the direction of power devices, electric power devices, transmission parts, etc., can solve the problems of reduced service life, bearing system and gear train wear, etc., to achieve small size, reduce the number of spare parts, good balance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

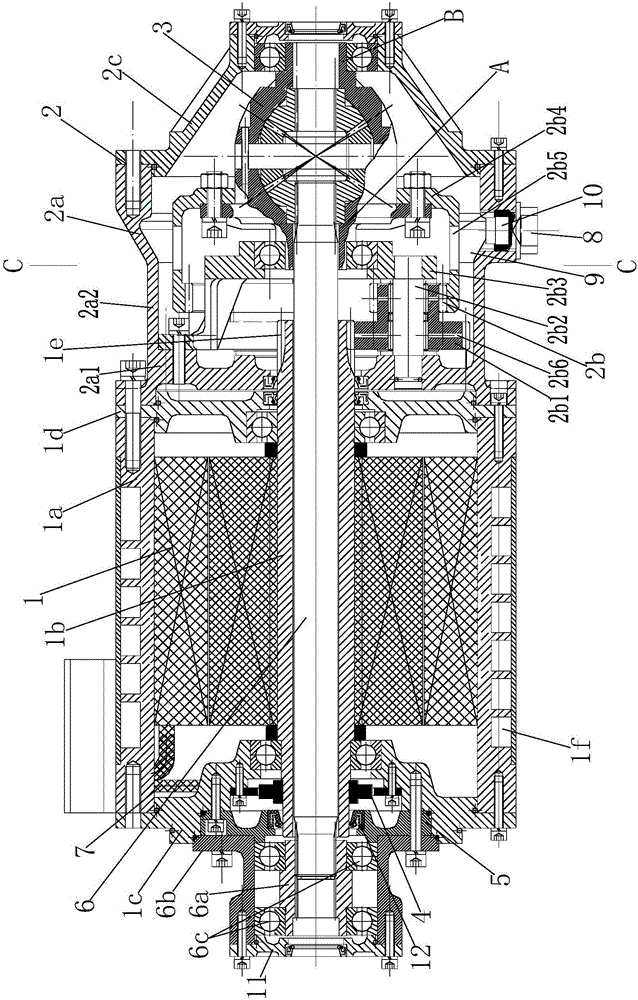

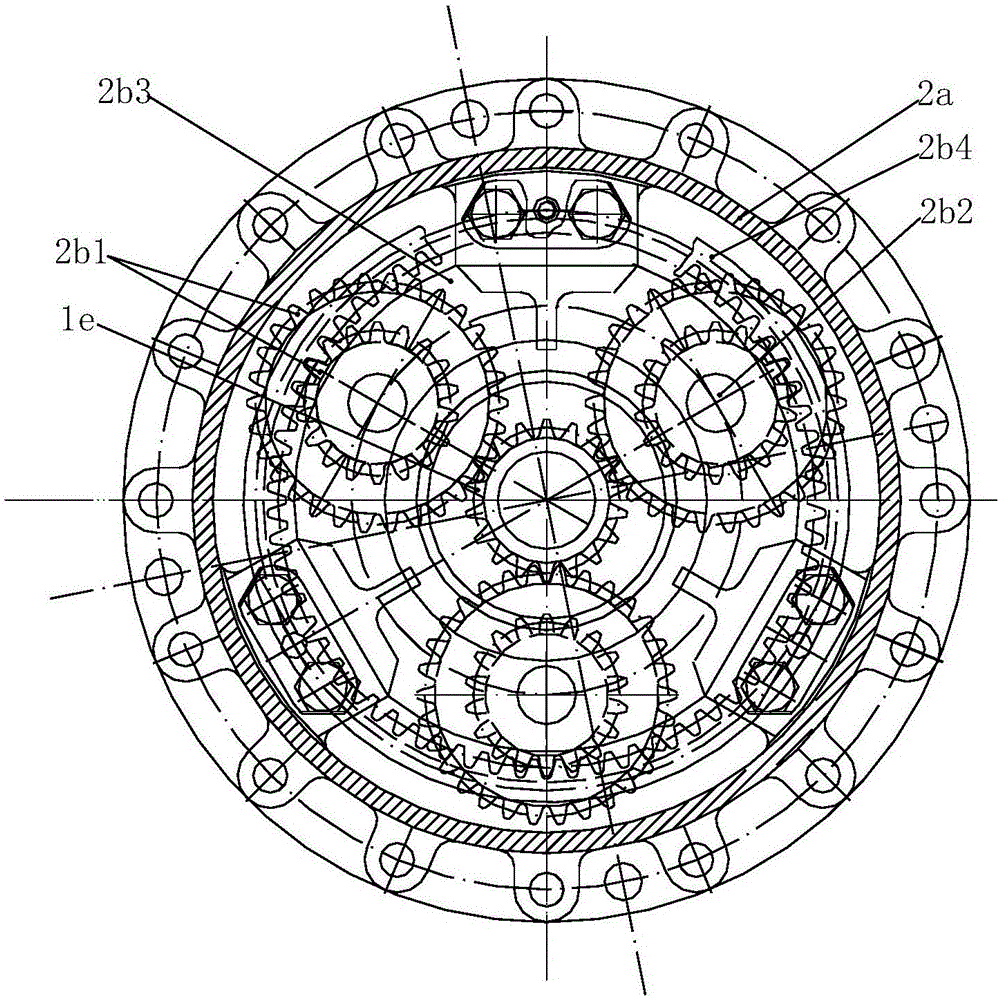

[0046] This embodiment provides a torque-variable differential drive device with coaxial input and output, including a motor subassembly 1, a torque converter subassembly 2 and a differential subassembly 3, and the motor subassembly 1 includes The motor housing 1a, the motor rear end cover 1c and the motor front end cover 1d installed at both ends of the motor housing 1a respectively, and the rotor shaft 1b movably installed on the motor rear end cover 1c and the motor front end cover 1d, The rotor shaft 1b is a hollow structure; the torque converter subassembly 2 includes a torque converter housing 2a, a speed change mechanism 2b and a torque converter end cover 2c installed at the front end of the torque converter housing 2a, the The rear end cover part 2a1 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com