Bogie skirting board installation structure of high-speed EMU

An installation structure and bogie technology, applied in the direction of bogie, railway car body, transportation and packaging, etc., can solve the problems such as vibration noise, loose skirt lock thread, skirt plate falling off, etc. Air drag reduction effect, increase service life, avoid collision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

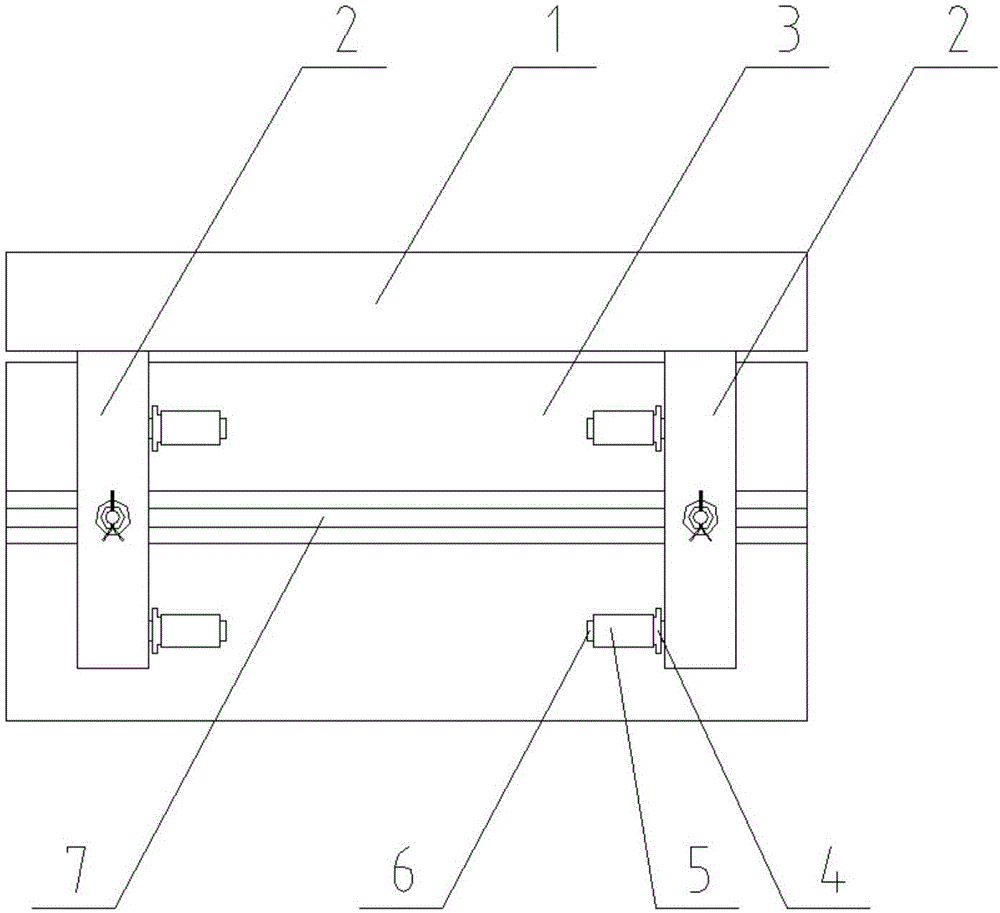

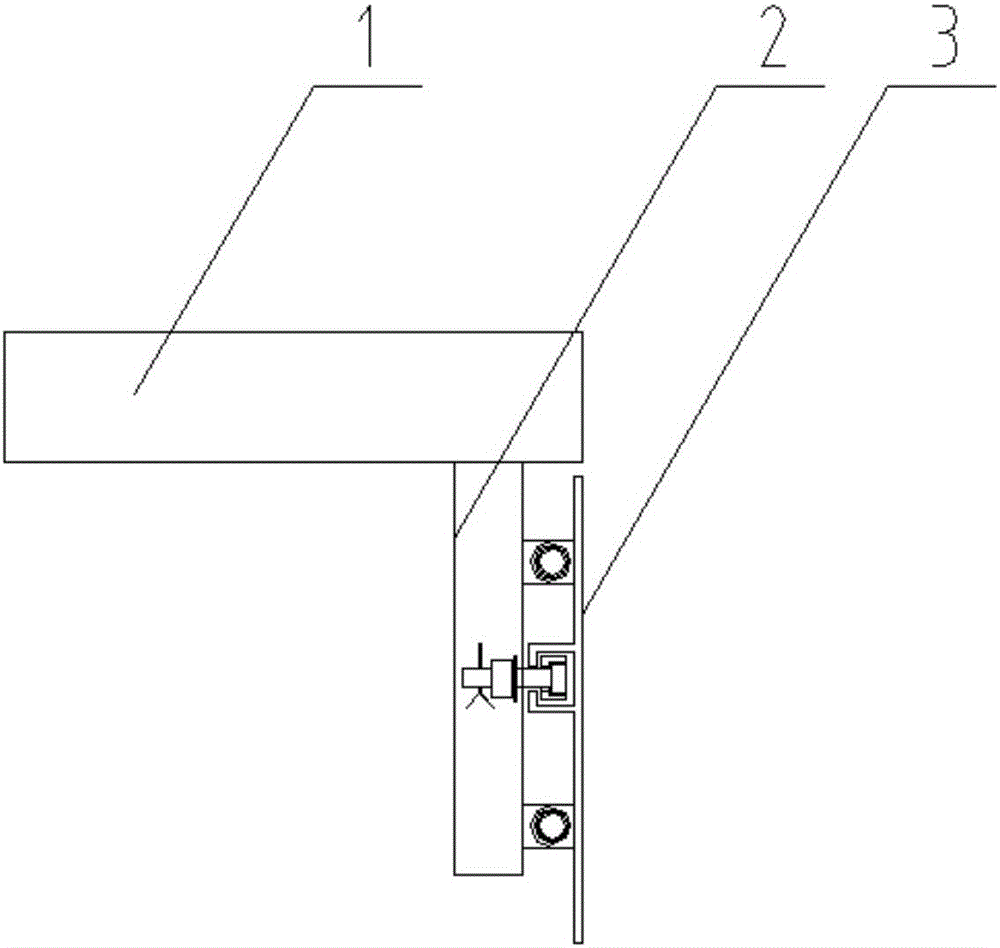

[0017] refer to figure 1 , figure 2 , the present invention includes a bogie skirt plate 3, a fixed bracket 2, an anti-rotation slider 9, a fastening bolt 8, a locknut 11, and a safety pin 12, and four sleeves 5 are arranged on the bogie skirt plate, and the The fixed bracket is provided with 4 fixed pins 6, and the 4 sockets of the bogie skirt plate and the 4 fixed pins of the fixed bracket are inserted and installed. The inner surface of the bogie skirt plate is provided with a chute 7, and an anti-rotation The slider 9 and the fastening bolt 8 are placed in the anti-rotation slider 9, and pass through the fixed bracket 2 to fasten the bogie skirt and the fixed bracket together through the locknut 11 and the safety pin 12 to form a stable anti-rotation Loose structure.

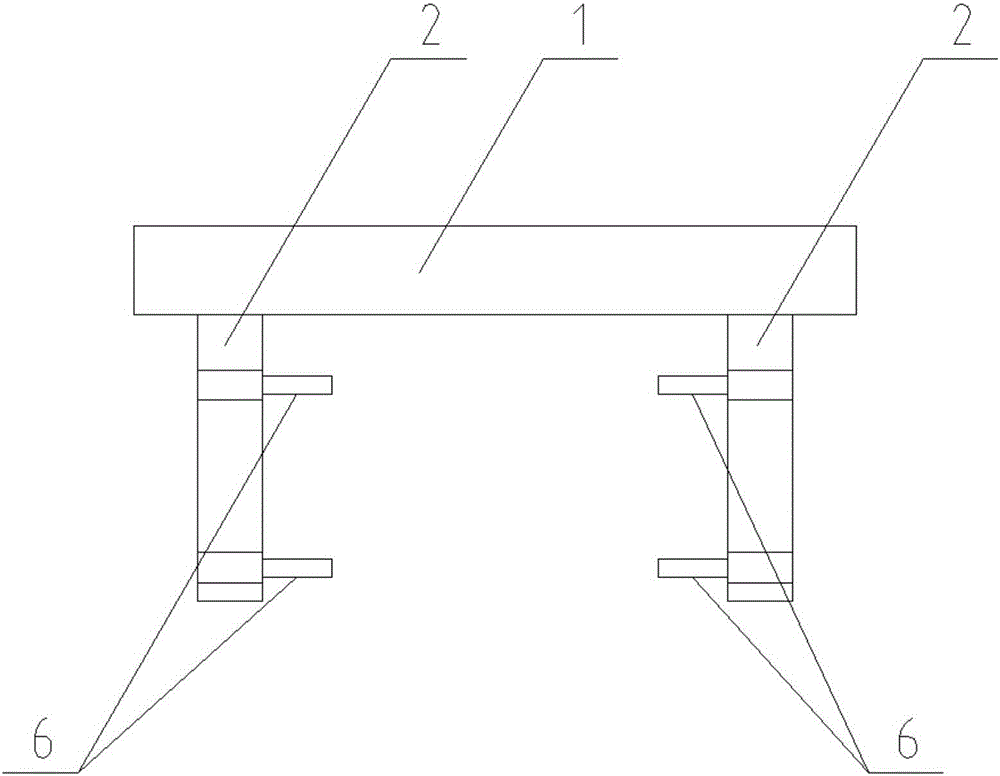

[0018] refer to image 3 , Figure 4 , a fixed bracket 2 is arranged under the side beam 1 of the underframe of the vehicle body, and a fixed pin 6 is arranged on the fixed bracket 2 .

[0019] refer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com