Undetachable tube connector and method of preventing detachment of tube connector

A pipe joint and body technology, applied in the field of pipe joints, can solve the problems of refrigerant leakage, non-disassembly, and expansion of the use range of flammable refrigerants, and achieve the effects of easy installation, convenient processing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

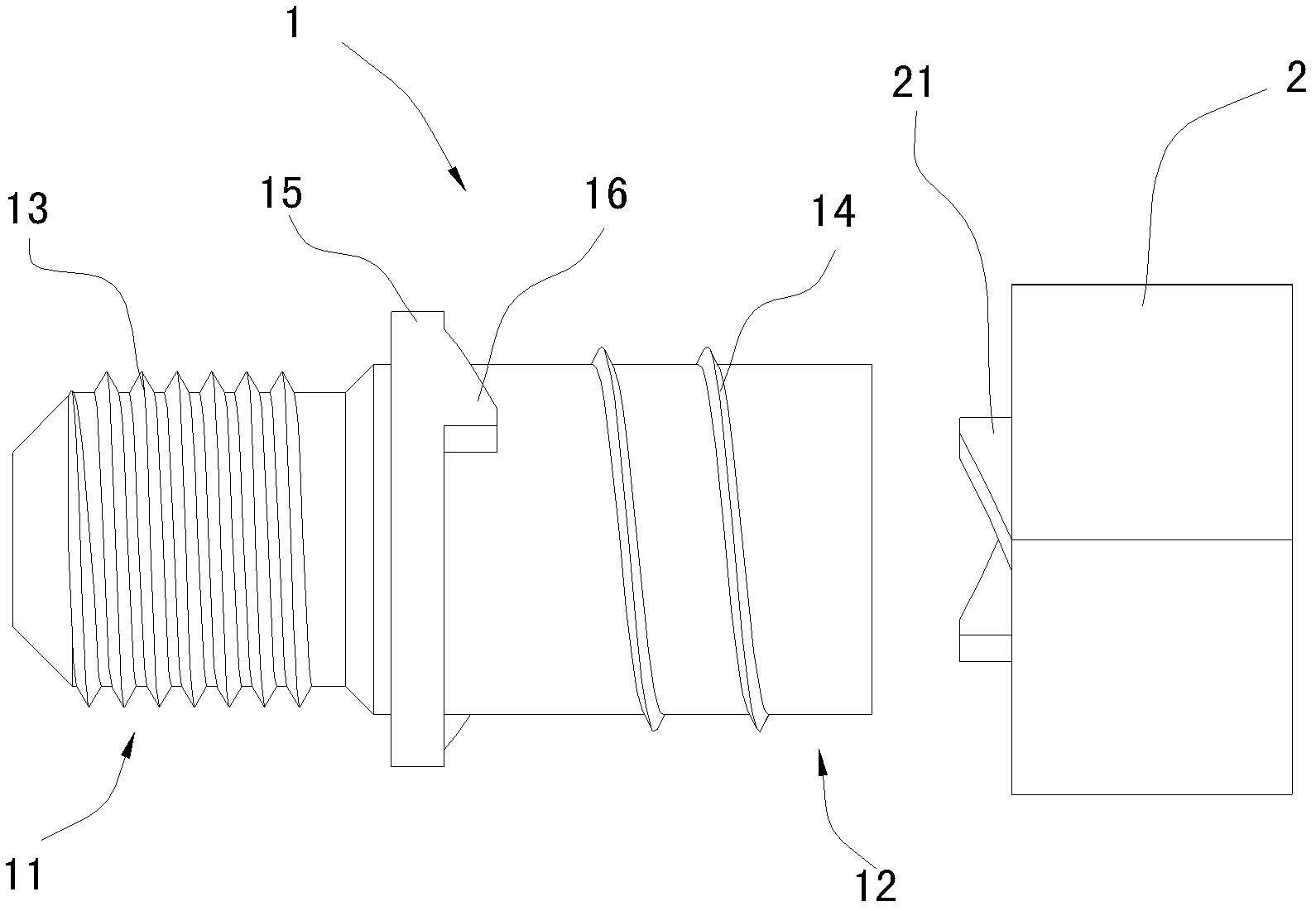

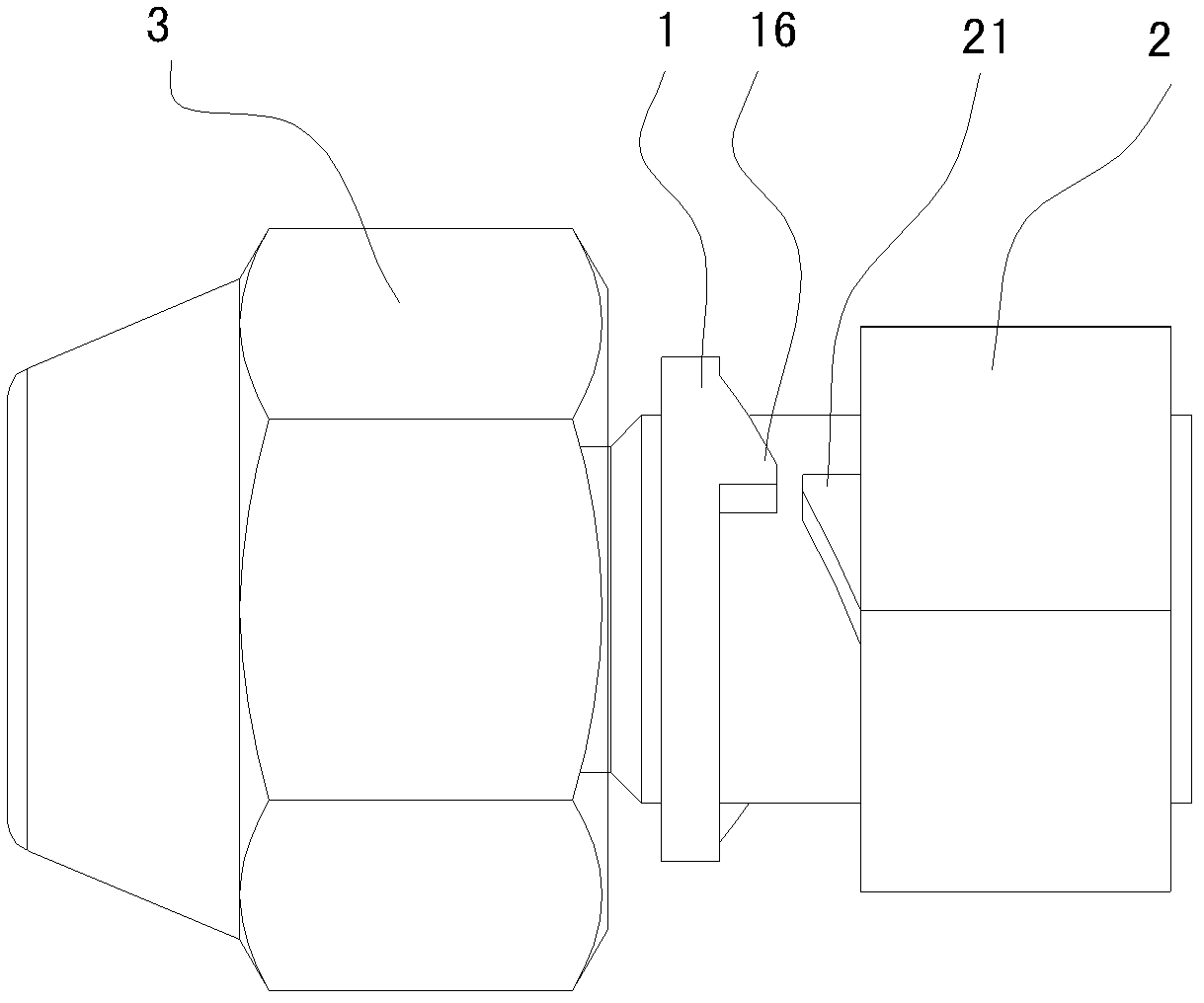

[0028] see Figure 1 to Figure 3 , the non-detachable pipe joint in this embodiment includes a pipe joint body 1 independent of each other and a rotating part 2 for tool rotation, the first end 11 and the second end 12 of the pipe joint body 1 are respectively provided with first external threads 13 and the second external thread 14. The first external thread 13 is used to connect with the union nut 3, and the second external thread 14 is used to connect with the rotating part 2, so that the rotating part 2 remains on the pipe joint body 1, and prevents the rotating part 2 from breaking away from the pipe joint body 1 when it vibrates. ring. Preferably, the pitch of the second external thread 14 is greater than the pitch of the first external thread 13, the lead angle of the second external thread 14 is greater than the lead angle of the first external thread 13, and the rotating part 2 The withdrawal stroke is greater than the withdrawal stroke of the union nut 3 threadedly...

Embodiment 2

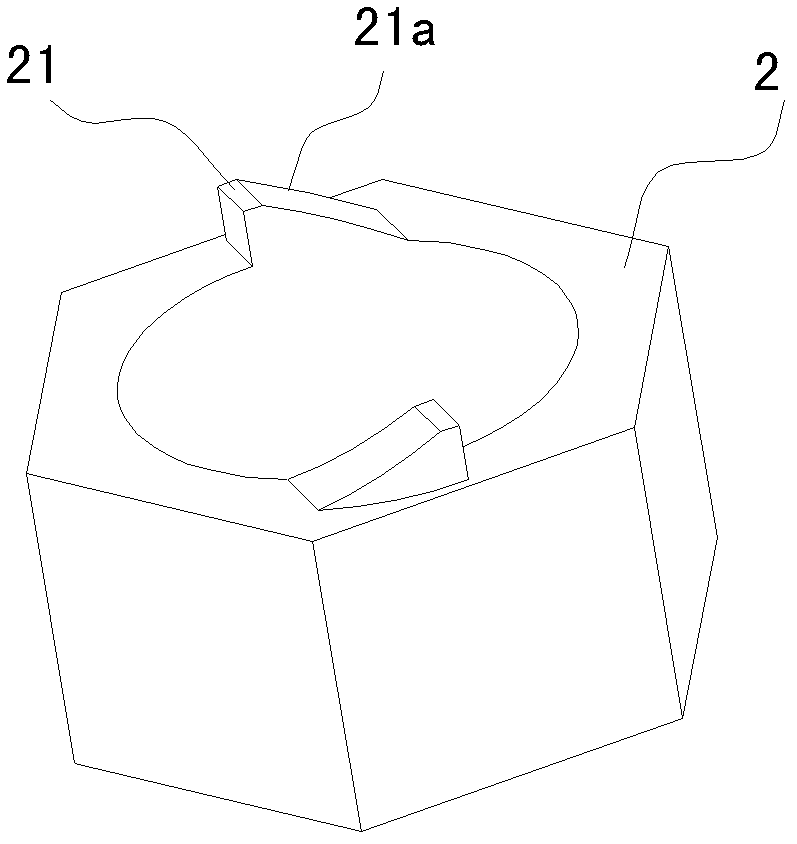

[0034] see Figure 4 and Figure 5 The difference between this embodiment and Embodiment 1 is that: the active part is two notches 22 arranged obliquely at one end of the rotating part 2, and the driven part is arranged on the outer wall of the middle part of the pipe joint body 1 Two positioning posts 17 extending outward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com