Front lower fender of engine and truck

A fender and engine technology, applied in the direction of the deflector, upper structure, vehicle parts, etc., can solve the problems of belt wear, increase vehicle resistance, belt slippage, etc., achieve reasonable structural design, prolong service life, and reduce economic burden. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

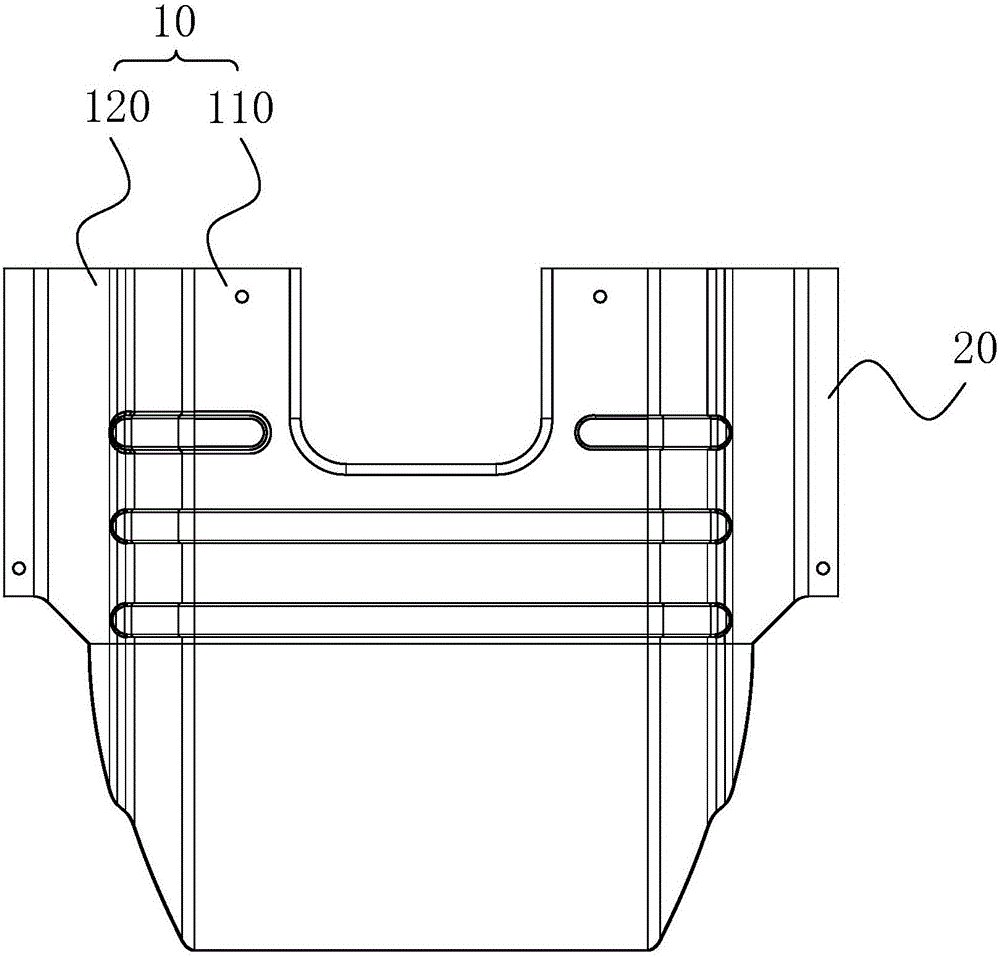

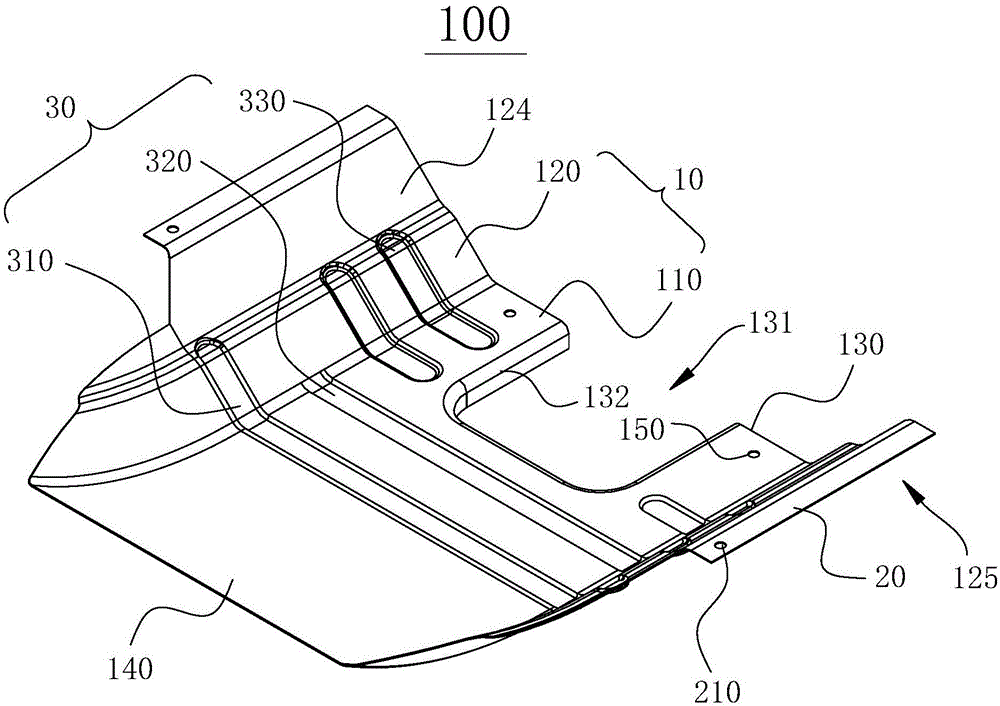

[0033] Please refer to figure 1 , the present embodiment provides a front lower fender 100 of an engine, which includes a fender body 10 and a connecting portion 20 .

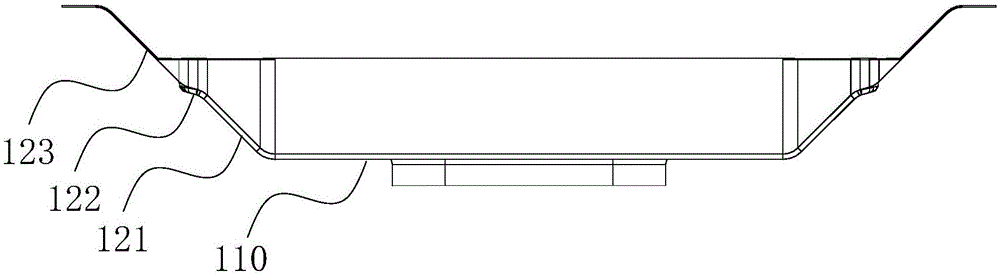

[0034] like figure 2 As shown, the fender body 10 includes a bottom plate 110 and two side plates 120. The side plate 120 is divided into a first side plate 124 and a second side plate 125. The two side plates 120 are symmetrically arranged on both sides of the bottom plate 110. The plate 120 is inclined relative to the bottom plate 110, that is, there is an included angle between the side plate 120 and the bottom plate 110 (such as image 3 shown).

[0035] In this embodiment, the fender body 10 includes a first end 130 and a second end 140 disposed opposite to each other. The first end 130 is provided with a U-shaped notch 131, and the opening of the U-shaped notch 131 faces away from the second end 140, that is, as figure 2 As shown in , the U-shaped opening faces to the right. The edge of the second ...

no. 2 example

[0049] This embodiment provides a truck, including the vehicle frame and the fender 100 at the front lower part of the engine provided by the first embodiment. For other unmentioned parts, refer to the first embodiment or the prior art.

[0050] In this embodiment, the engine is fixed on the vehicle frame, and the front lower fender 100 of the engine is located at the lower front position of the engine, and is connected with the vehicle frame by fasteners. The front lower fender 100 of the engine is arranged outside the engine, so that the engine has a shielding layer, which can block the muddy water and dust splashed by the vehicle during work, so that the engine is well maintained and the service life of the engine is extended, which is equivalent to increasing the service life of the truck , for the user to reduce the economic burden.

[0051] In summary, the present invention provides an engine front lower fender and a truck. The structure of the engine front lower fender ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com