Automatic film laminating machine

A film laminating machine and automatic technology, applied in packaging, climate sustainability, final product manufacturing, etc., can solve the problems of manual film lamination difficulty and labor intensity increase, inaccurate film lamination position, low film lamination accuracy, etc., to simplify the film lamination process , good consistency, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the specific drawings.

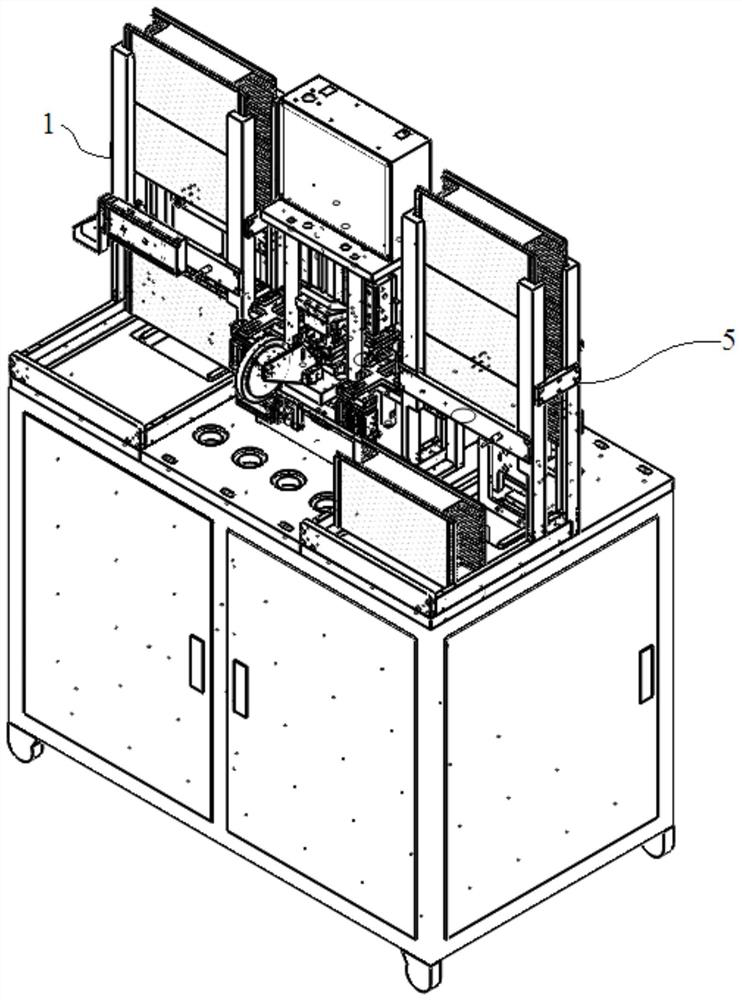

[0030] like figure 1 As shown, the automatic film laminating machine of the present invention includes a feeding component 1 , a material moving component 2 , a film pulling component 3 , a film pressing component 4 and a material receiving component 5 .

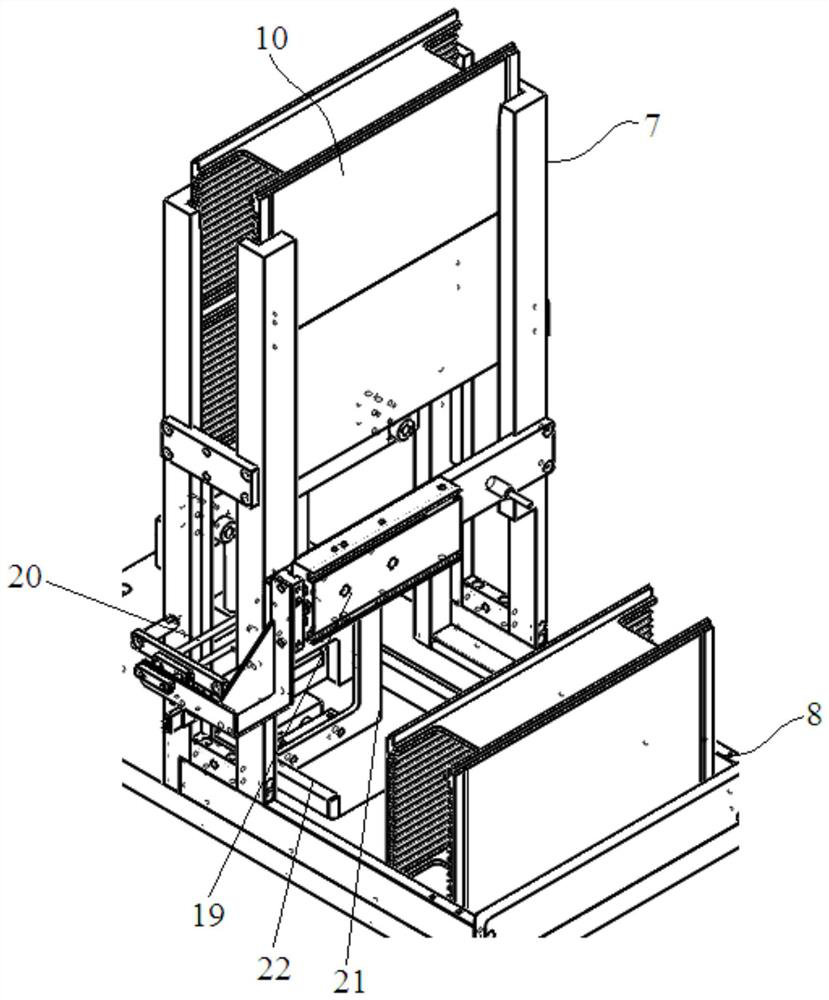

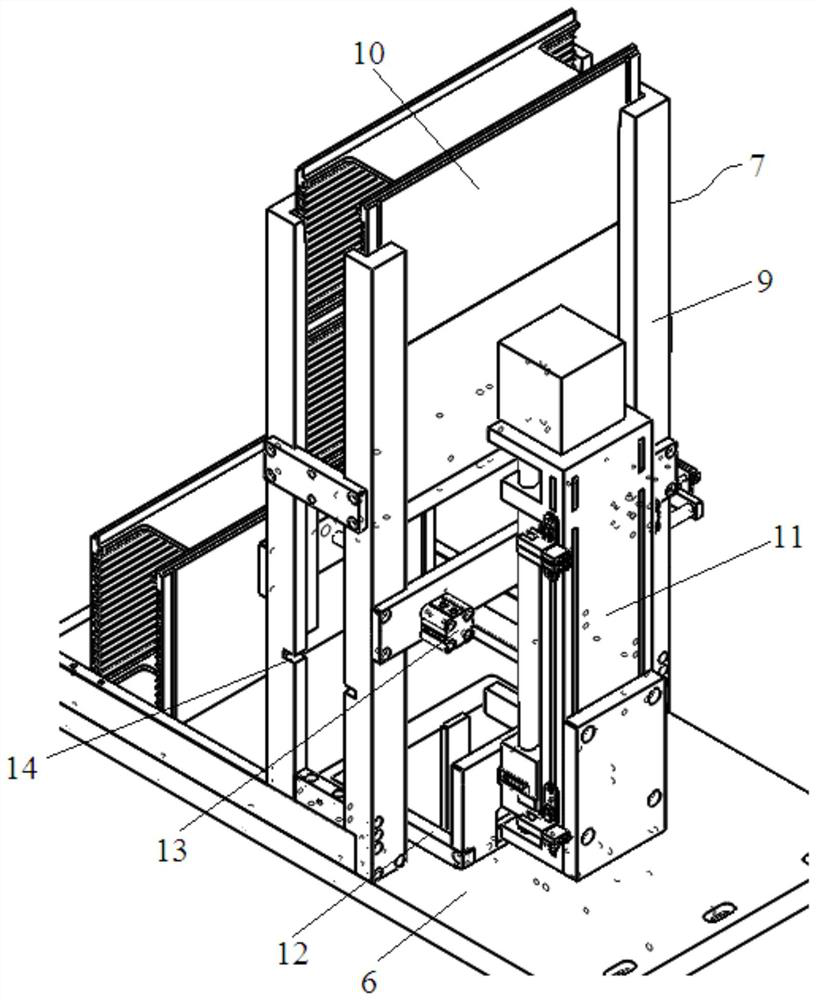

[0031] like figure 2 , image 3 As shown, the loading assembly includes a loading base plate 6 on which a loading area 7 and an empty material box area 8 are set. The loading area 7 is surrounded by four loading frames 9. The loading area 7 Containers 10 stacked in sequence from top to bottom are accommodated in the middle, and a lift 11 is installed on the side of the loading base plate 6 away from the empty container area 8. Located below the bottommost material box 10, a material pressing cylinder 13 is installed on one side of the charging area 7. When the extension rod of the material pressing cylinder 13 is ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com