Fixture holding mechanism

A technology of jigs and clamping mechanisms, which is applied in the direction of manufacturing tools, metal processing, workpiece clamping devices, etc. It can solve problems such as obstacles to the development of automation equipment, misalignment of pick-and-place positions, and inaccurate product alignment, etc., and achieves fast speed. , avoid repetitive actions, and facilitate the effect of taking and placing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

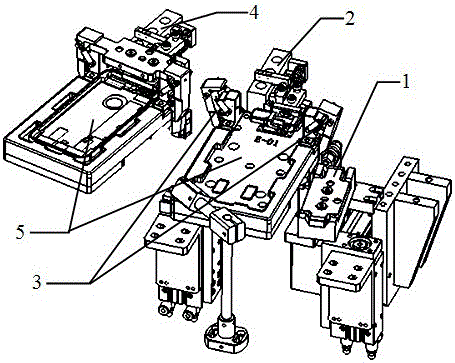

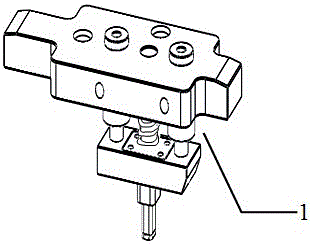

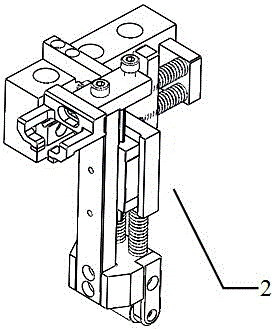

[0013] Fixture pressure holding mechanism, including glue pressure mechanism 1, pressure head mechanism 2, clamping mechanism 3, slotted jacking mechanism 4, workpiece fixture 5, characterized in that clamping mechanism 3 is divided into left and right parts, pressure head mechanism 2 Set between the left and right parts of the clamping mechanism 3, the glue pressing mechanism 1 is set on one side of the clamping mechanism 3, the slotted jacking mechanism 4 is set on the other side of the clamping mechanism 3, and the workpiece fixture 5 follows the position of the processing station. The different parts are respectively arranged under the glue pressing mechanism 1, the clamping mechanism 3, and the slotted jacking mechanism 4. Glue pressing mechanism 1 resets by spring. The pressure head mechanism 2 is reset by a spring. The clamping mechanism 3 clamps the workpiece thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com