Conjoined film laminating machine

A film machine and film wrapping technology, which is applied in packaging and other directions, can solve the problems of unguaranteed quality, time wasting, and easy generation of air bubbles, and achieve the effects of avoiding manual turning, overcoming cumbersome operations, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

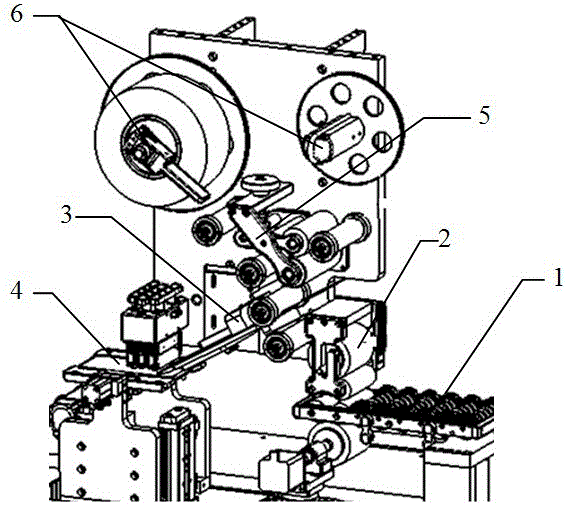

[0014] One-piece film laminating machine, including back dust sticking platform 1, front sticking dust wheel 2, clamping mechanism 3, three-axis linkage mechanism 4, feeding mechanism 5, film wrapping mechanism 6, characterized in that the front sticking dust wheel 2 is set on the back On the left side of the dust-sticking platform 1, the three-axis linkage mechanism 4 is arranged on the left side of the dust-sticking platform 1 on the back. On the upper part of the film mechanism 6, the clamping mechanism 3 is arranged on the three-axis linkage mechanism 4 and is located on the right side. The clamping mechanism 3 drives the rotatable clamping heads to clamp the workpiece through the cylinders on both sides. There are multiple feeding mechanisms 5, and multiple feeding mechanisms 5 are arranged side by side. The coating mechanism 6 is provided with a coating cutter. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com