Automatic feed type conveying cutting device for cutting of labeling mechanism

A technology of automatic feeding and cutting device, applied in the directions of labeling machine, transportation and packaging, labeling, etc., can solve the problems of waste, the release paper cannot be reused, etc., and achieve the effect of good effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

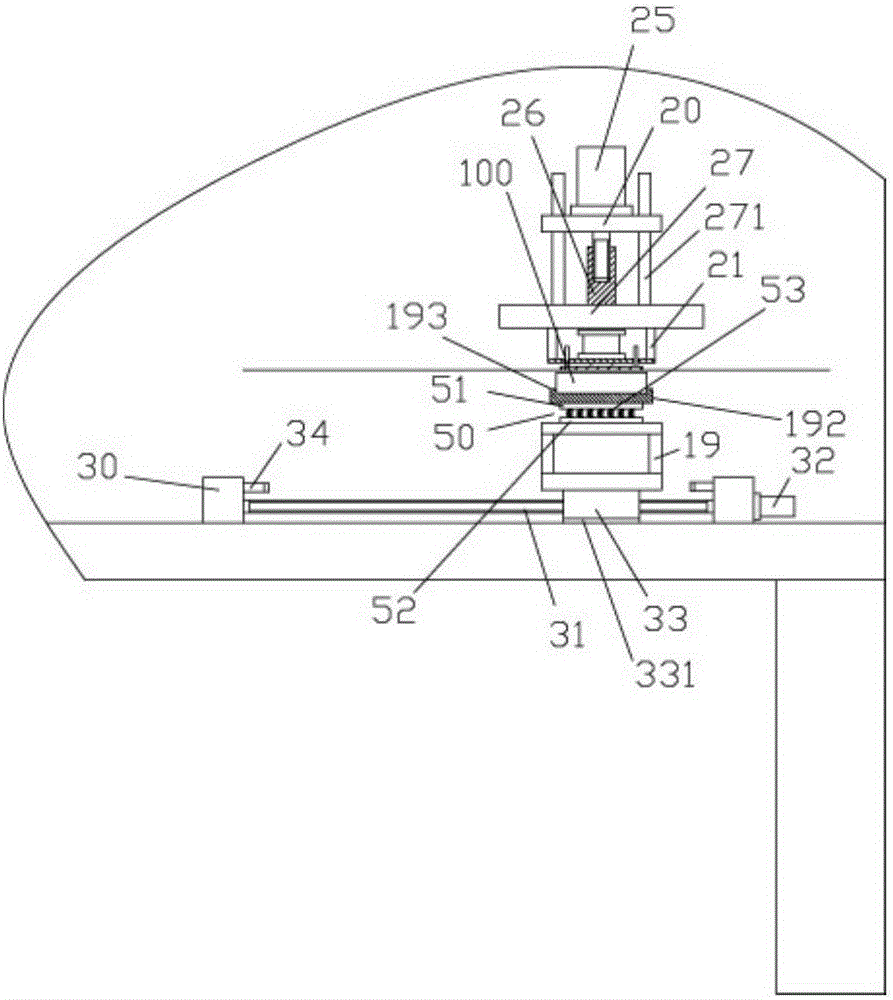

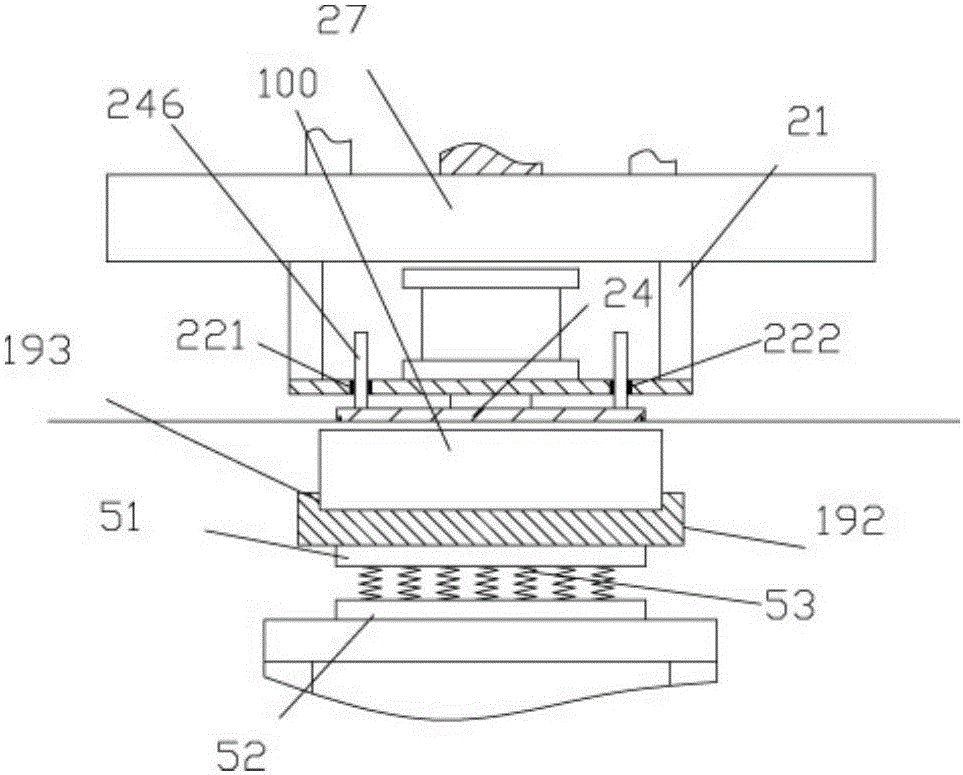

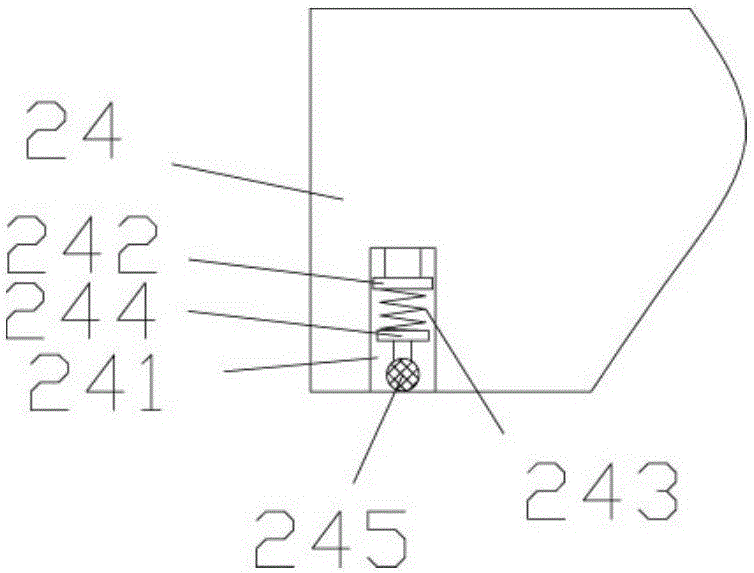

[0022] Examples, see e.g. Figure 1 to Figure 3 Shown, a kind of automatic feeding type cutting and labeling mechanism is used conveying and cutting device, comprises frame 10, and the rear side place top surface of the top plate of described frame 10 is fixed with main supporting board 11, and the front of described main supporting board 11 The connecting plate 20 is fixed on the wall, and the top surface of the connecting plate 20 is fixed with a primary lifting motor 25. The output shaft of the primary lifting motor 25 extends downwards from the connecting plate 20 and is screwed with a primary adjusting screw sleeve 26. The primary adjusting screw sleeve 26 The bottom end of the primary lifting plate 27 is fixed with a bottom frame 21, the top surface of the bottom plate 22 of the bottom frame 21 is fixed with a compression cylinder 23, and the push rod of the compression cylinder 23 passes through the bottom plate 22 and is fixed with cutting and pressing plate 24;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com